Reflector switching device with crank cam driven by lead screw to follow up

A screw drive and switching device technology, applied in installation, optics, instruments, etc., can solve problems such as complex limit and self-locking mechanisms, poor repeat positioning accuracy, complex processing and adjustment, etc., to achieve stable and smooth transmission, ensure The effect of precision, processing and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

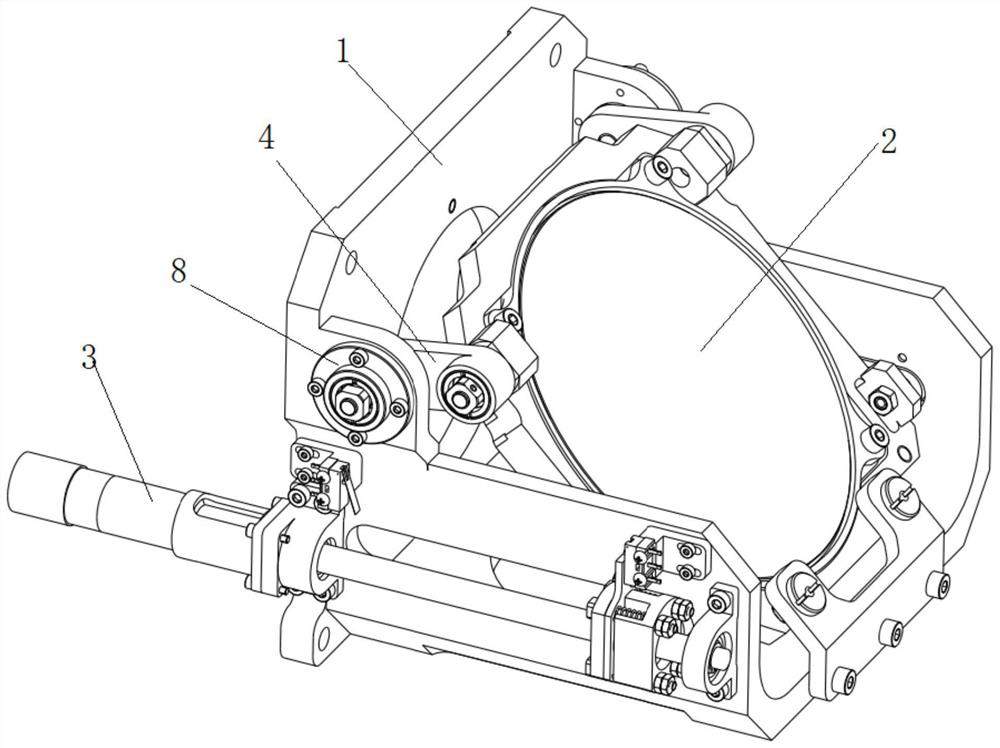

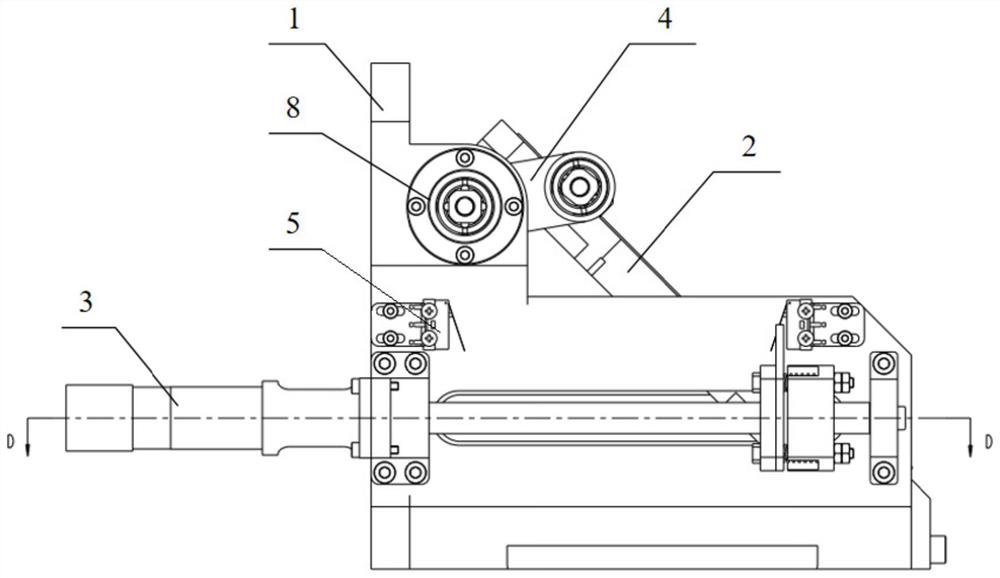

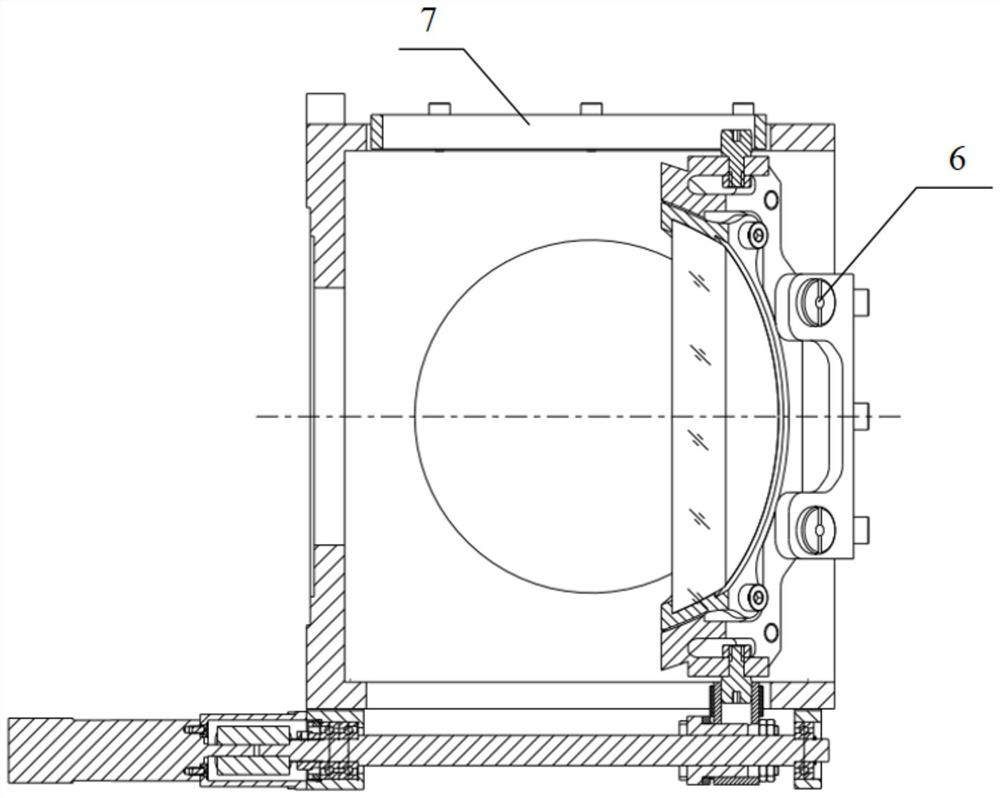

[0028] Such as Figure 1 to Figure 9 As shown, a screw-driven crank cam follow-up mirror switching device includes a support 1, a reflector assembly 2 and a driving mechanism 3 installed on the support 1; The crank 4, the two sides of the lower part are provided with forward and backward linear grooves 7, the middle of the lower front side is provided with a magnet 6 for limiting, and the two ends of the linear groove 7 on one side are provided with micro switches 5, and the upper two sides of the mirror assembly 2 respectively pass through Rotating shaft 13 is connected with the swing end of crank 4 on both sides, cam follower 12 is arranged on both sides of the lower part, and magnetic attraction part 14 corresponding to magnet 6 is arranged in the middle of the lower part front side, and driving mechanism 3 includes ball screw 16 and screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com