Milling device with automatic dredging function for rice processing

A rice processing and grinding technology, applied in the application, solid separation, grain smoothing and other directions, can solve the problems of rice flour accumulation on the top of the separation screen, clogging of the separation screen, reducing the convenience of the grinding device, etc. The effect of smoothness, improving convenience and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

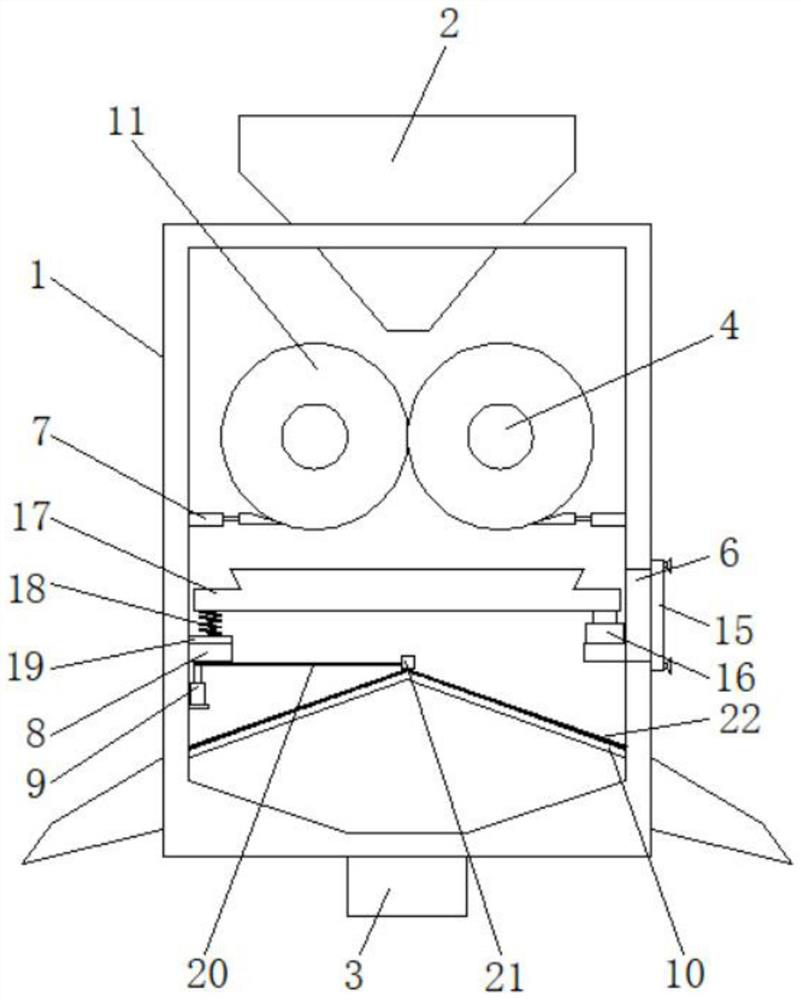

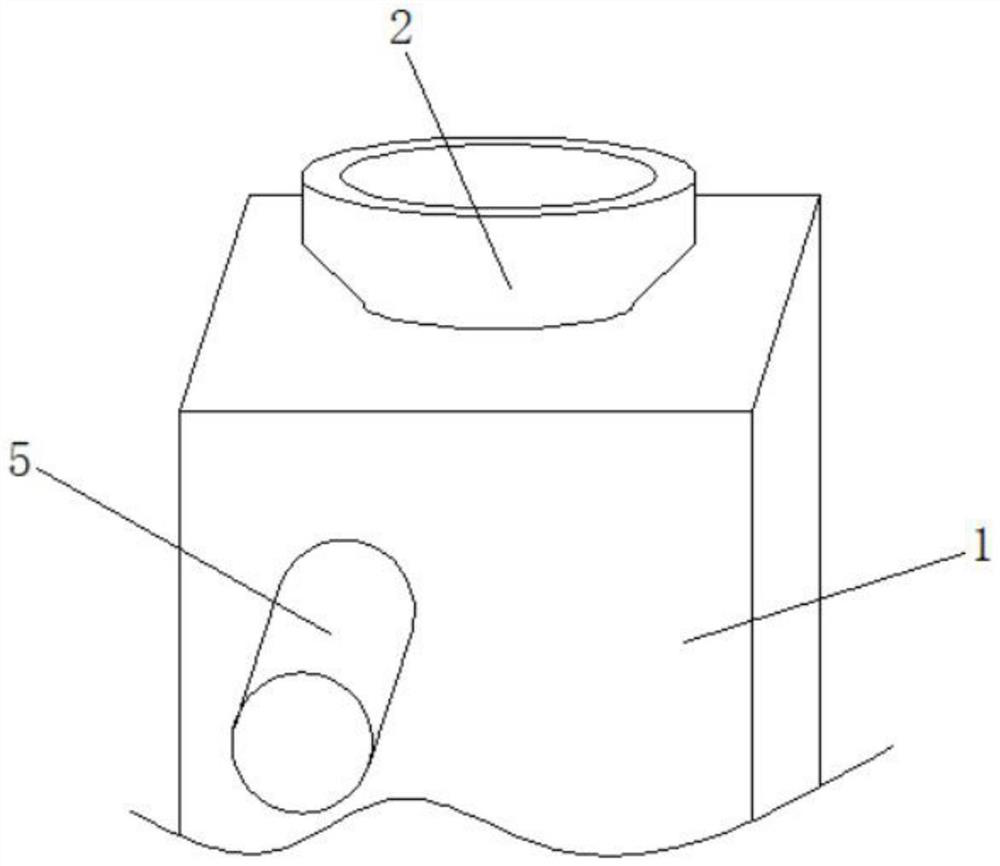

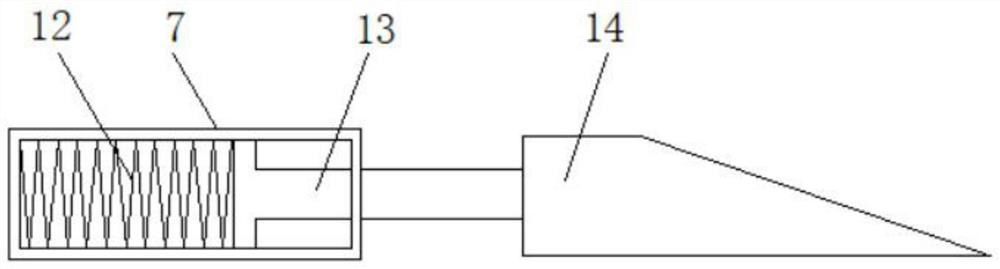

[0015] see Figure 1-Figure 3 , the present invention provides a technical solution: a milling device with automatic dredging for rice processing, comprising a milling box 1, the milling box 1 is provided with a feed hopper 2, a discharge chute 3, a bearing 4, a drive Motor 5, through groove 6, hollow column 7, magnetic suction plate 8, electric push rod 9 and separation net plate 10, described feeding hopper 2 is fixedly connected on the upper end of described milling box 1, and described treatment discharge trough 3 are provided in three, and are respectively fixedly connected to the left surface, right surface and bottom of the grinding box 1, the bearing 4 is fixedly connected to the inner wall of the grinding box 1, and the driving motor 5 is fixedly connected to the The outer surface of the grinding box 1, the through groove 6 is located at the right end of the grinding box 1, the hollow column 7 is fixedly connected to the inner wall of the grinding box 1, and the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com