Kitchen waste dry-wet separation treatment device

A kitchen waste, dry and wet separation technology, applied in separation methods, filtration separation, grain processing and other directions, can solve the problem of inconvenient use of viruses and pathogenic bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

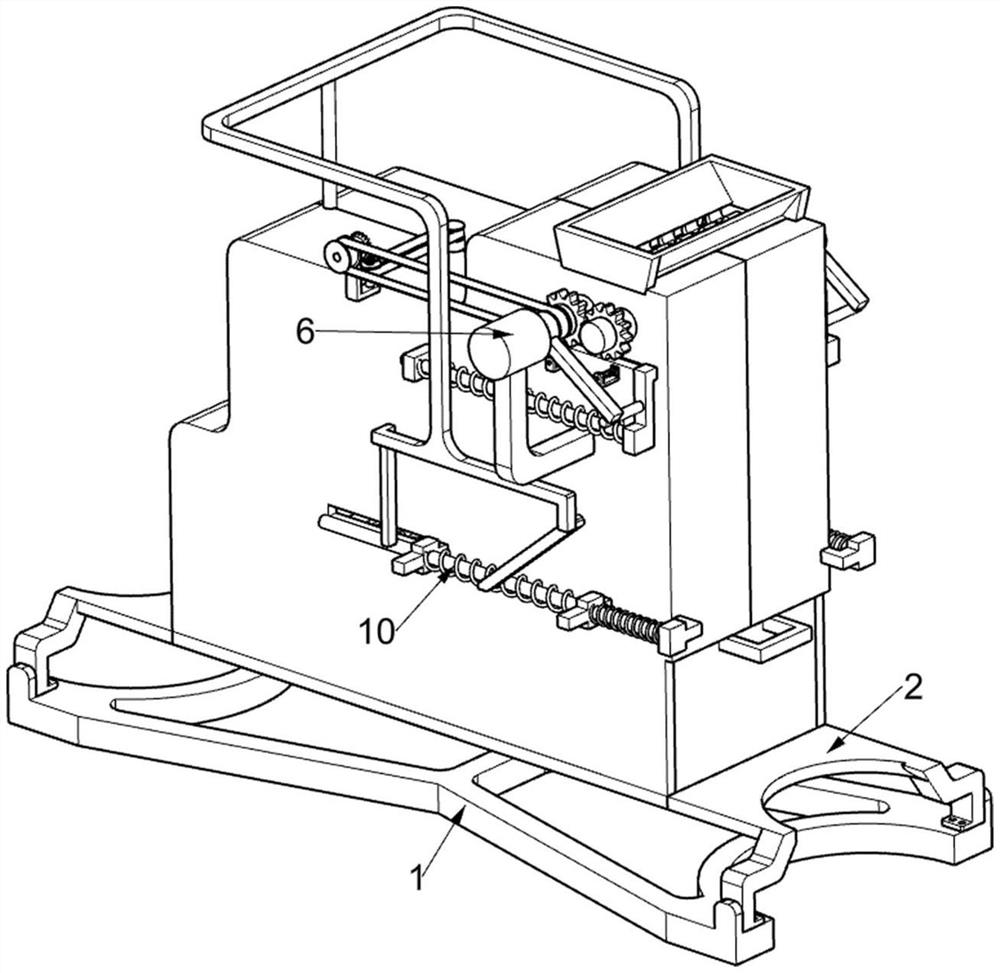

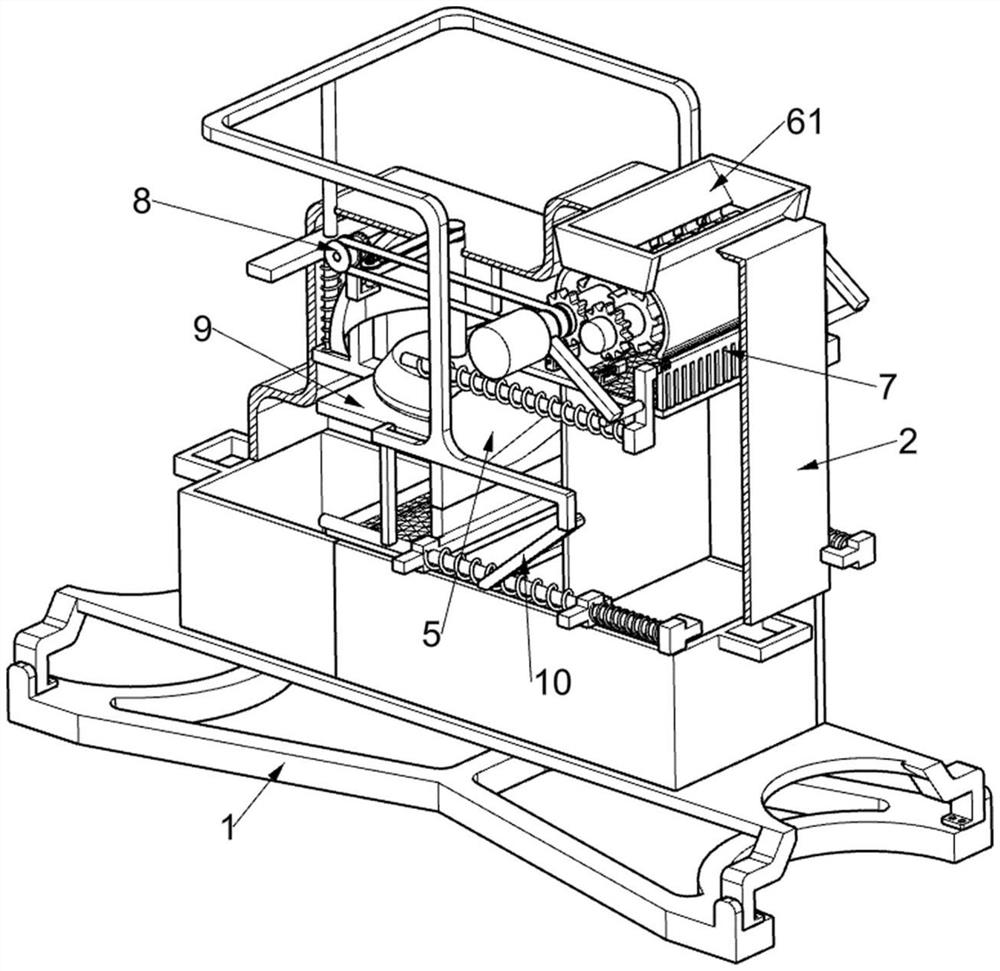

[0037] A kind of dry-wet separation processing device for kitchen waste, such as Figure 1-8As shown, it includes a bottom frame 1, a fixed frame 2, a solid holding frame 201, a liquid holding frame 202, a first filter screen 3, a second filter screen 4, an arc plate 5, a crushing mechanism 6 and a first push-out mechanism 7. The bottom frame 1 is connected to the fixed frame 2 by means of fasteners. The solid storage frame 201 is slidably connected to the bottom of the fixed frame 2. The liquid storage frame 202 is also slidably connected to the bottom of the fixed frame 2. The fixed frame 2 is provided with a first filter screen 3 for filtering the moisture in the kitchen waste, the second filter screen 4 is also arranged in the fixed frame 2, the curved plate 5 is fixedly installed in the fixed frame 2, the curved plate 5 and The first filter screen 3 is fixedly connected, the fixed frame 2 is provided with a crushing mechanism 6 for crushing kitchen waste, and the fixed fr...

Embodiment 2

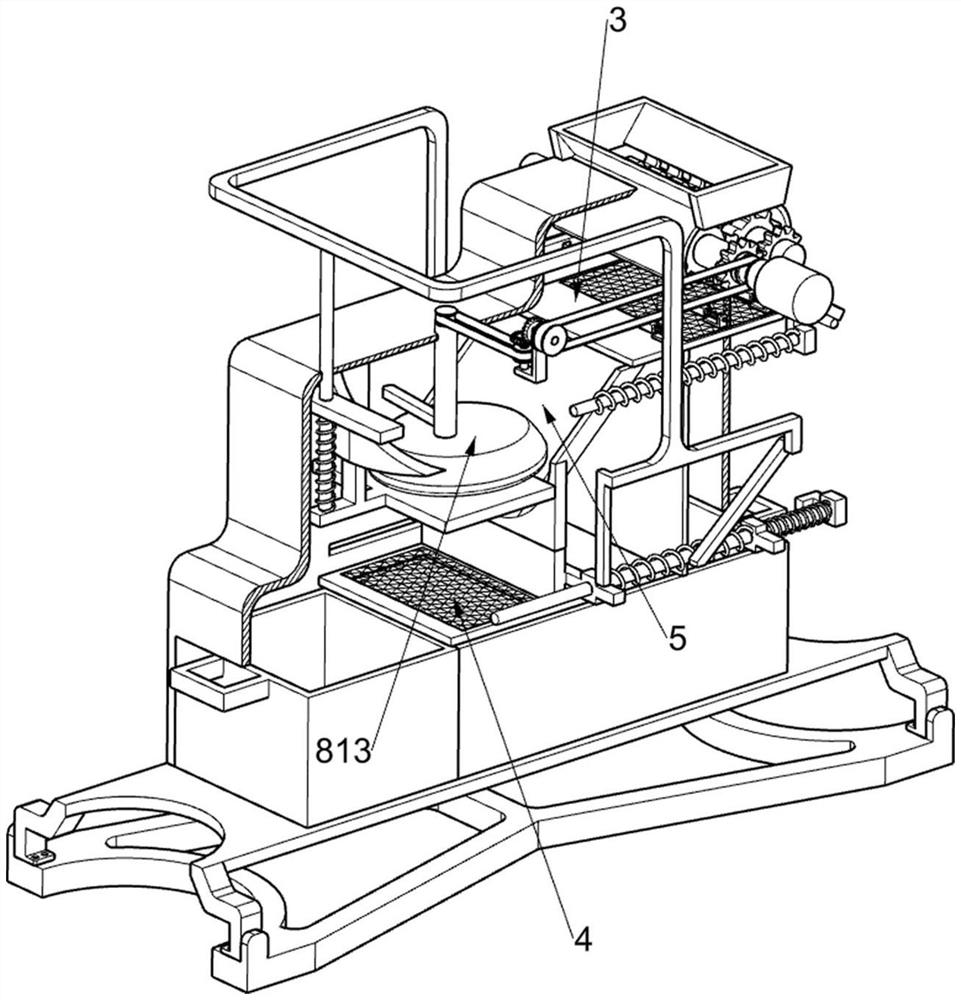

[0043] On the basis of Example 1, such as Figure 9-10 As shown, a grinding and pressing mechanism 8 is also included. The fixed frame 2 is provided with a grinding and pressing mechanism 8. The grinding and pressing mechanism 8 is used to further crush kitchen waste. The grinding and pressing mechanism 8 includes a second fixed frame 81 and a first rotating shaft 82. , the second rotating wheel 83, the first bevel gear 84, the first belt 85, the second rotating shaft 86, the third rotating wheel 87, the second bevel gear 88, the third rotating shaft 89, the fourth rotating wheel 811, the second The belt 812 and the grinding plate 813 are fixedly connected with a second fixed frame 81 above the fixed frame 2, and the second fixed frame 81 is rotatably connected with a first rotating shaft 82, and is fixedly connected with a second rotating wheel on the first rotating shaft 82. 83, one end of the first rotating shaft 82 away from the second rotating wheel 83 is provided with a ...

Embodiment 3

[0046] On the basis of Example 2, such as Figure 9 , 11 As shown, an extruding mechanism 9 is also included, and the fixed frame 2 is provided with an extruding mechanism 9. The extruding mechanism 9 is used to extrude the moisture in the kitchen waste. The extruding mechanism 9 includes a fixed plate 91, a second slide Rod 92, extrusion plate 93, arc frame 94, third return spring 95 and rotating bar 96, fixed plate 91 is fixedly installed in fixed frame 2, and the middle part of fixed plate 91 is connected with the second slide bar 92 in the mode that can lift , the second slide bar 92 passes through the fixed frame 2, and the bottom end of the second slide bar 92 is welded with an extruding plate 93, which is used to extrude the kitchen waste on the second filter screen 4, and the extruding plate 93 An arc-shaped frame 94 is fixedly installed on the top, and the arc-shaped frame 94 is in contact with the fixed frame 2. A third return spring 95 is connected to the extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com