Tampon with built-in catheter easy to push and preparation method of tampon

A technology of tampons and catheters, applied in the direction of tampons, absorbent pads, etc., can solve the problems of inconvenient carrying, wear and tear of users, increase the difficulty of operation, etc., and achieve the effect of being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A tampon with a built-in easy-to-push catheter and a preparation method thereof, comprising the following operations:

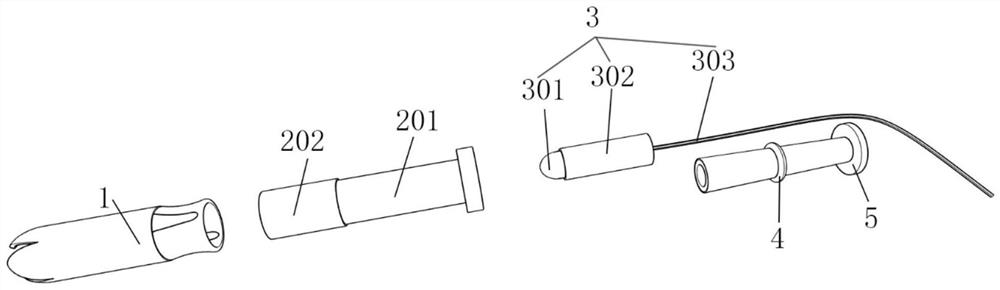

[0036] S1, cotton sliver production: make cotton core 301, and the covering layer 302 on the outer surface of cotton core 301 is mesh structure simultaneously, and combine with cotton thread 303 at the end of cotton core 301, extrusion molding, and covering layer 302 Thickening the connection with the cotton thread 303 can complete the production of the sliver;

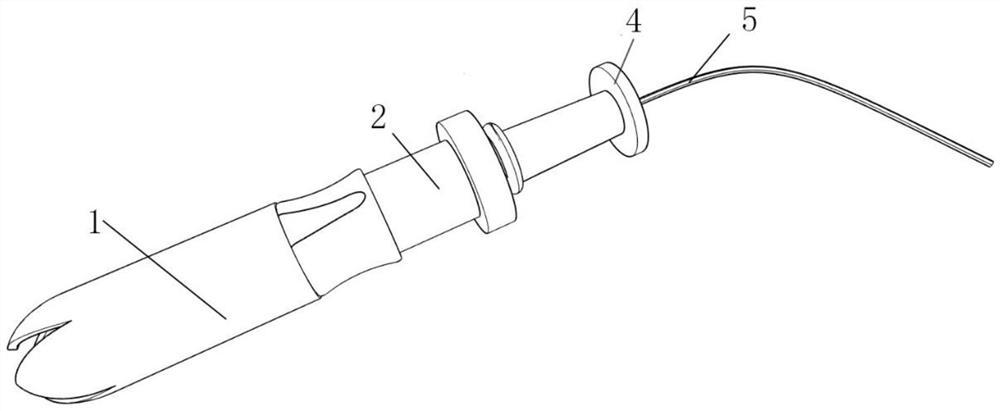

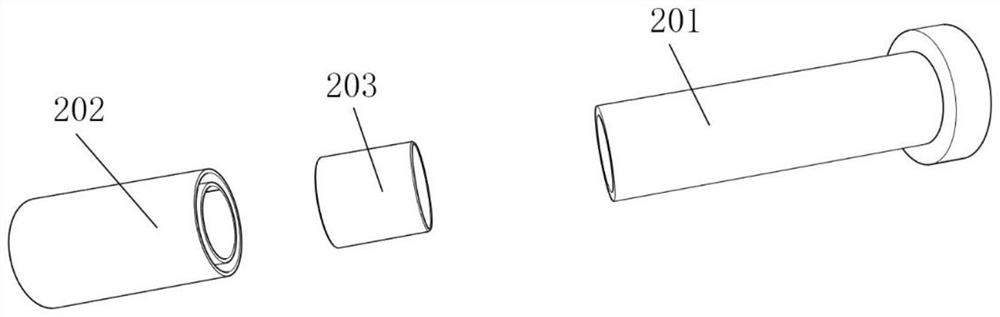

[0037] S2, tampon installation: install the tampon 3 in the auxiliary pushing device 2, fix the wrapping structure 202 on the inner wall of the catheter 1, fix the rubber ring 4 in the extruding rod 201 at this time, and make the lubricating bag 203 pack at the same time In the extrusion groove 2022 of the wrapping structure 202, ensure that the cotton thread 303 stays on the inner wall of the push rod 5, while the cotton thread 303 stays on the outer wall. At this time, the installation and p...

Embodiment 1

[0039]When in use, the push rod 5 is pushed so that the rubber ring 4 touches the extrusion rod 201. When the extrusion rod 201 contacts the rubber ring 4, the extrusion rod 201 moves toward the extrusion groove 2022 due to the action of the rubber ring 4. The bottom moves, and when the bottom of the extruding rod 201 touches the lubricating bag 203, it will continue to extrude the lubricating bag 203, causing the lubricating bag 203 to rupture. At this time, the lubricating fluid in the lubricating bag 203 will flow out. , so that the extrusion rod 201 cannot move forward, thereby due to the soft rubber structure of the rubber ring 4, the restriction between the extrusion rod 201 and the rubber ring 4 is released, thereby continuing to push the push rod 5, so that the tampon 3 moves toward the nozzle, When the tampon 3 touches the mesh 2021, the lubricating fluid from the lubricating bag 203 will flow out from the mesh 2021, so that the surface of the tampon 3 is attached with...

Embodiment 2

[0041] When in use, the push rod 5 is pushed so that the rubber ring 4 touches the extrusion rod 201. When the extrusion rod 201 contacts the rubber ring 4, the extrusion rod 201 moves toward the extrusion groove 2022 due to the action of the rubber ring 4. The bottom end moves, and when the bottom end of the extruding rod 201 touches the lubricating bag 203, it will continue to extrude the lubricating bag 203, so that the lubricating bag 203 contacts the piercing cone 2023 at the bottom of the extrusion groove 2022, so that the piercing cone 2023 Puncture the lubricating bag 203, and now the lubricating fluid in the lubricating bag 203 will flow out. At this time, due to the resistance, the extruding rod 201 cannot move forward, so that the extruding rod 201 and the rubber ring 4 will contact each other due to the soft rubber structure of the rubber ring 4. The ring 4 limit is released, so as to continue to push the push rod 5, so that the tampon 3 moves to the nozzle. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com