Acoustophoretic composite flow focusing micro-nano jet printing method and device

A composite flow and inkjet printing technology, applied in printing, climate sustainability, typewriters, etc., can solve problems such as difficult steps, inability to achieve precise control of fine patterns, difficulty in reducing droplet size, etc., and achieve the effect of high-resolution printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

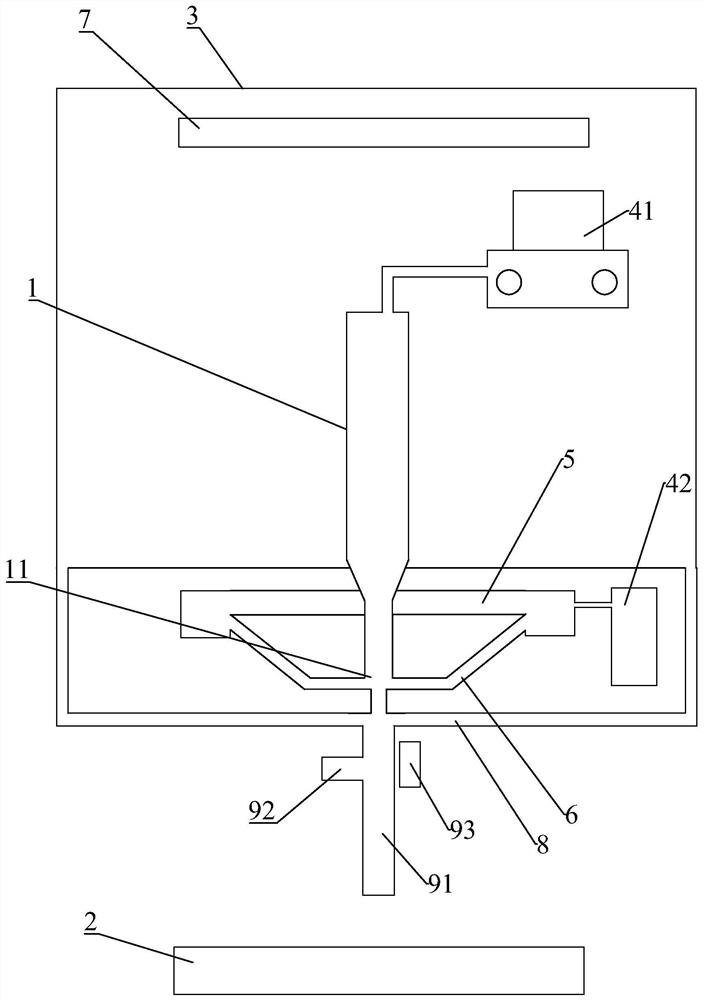

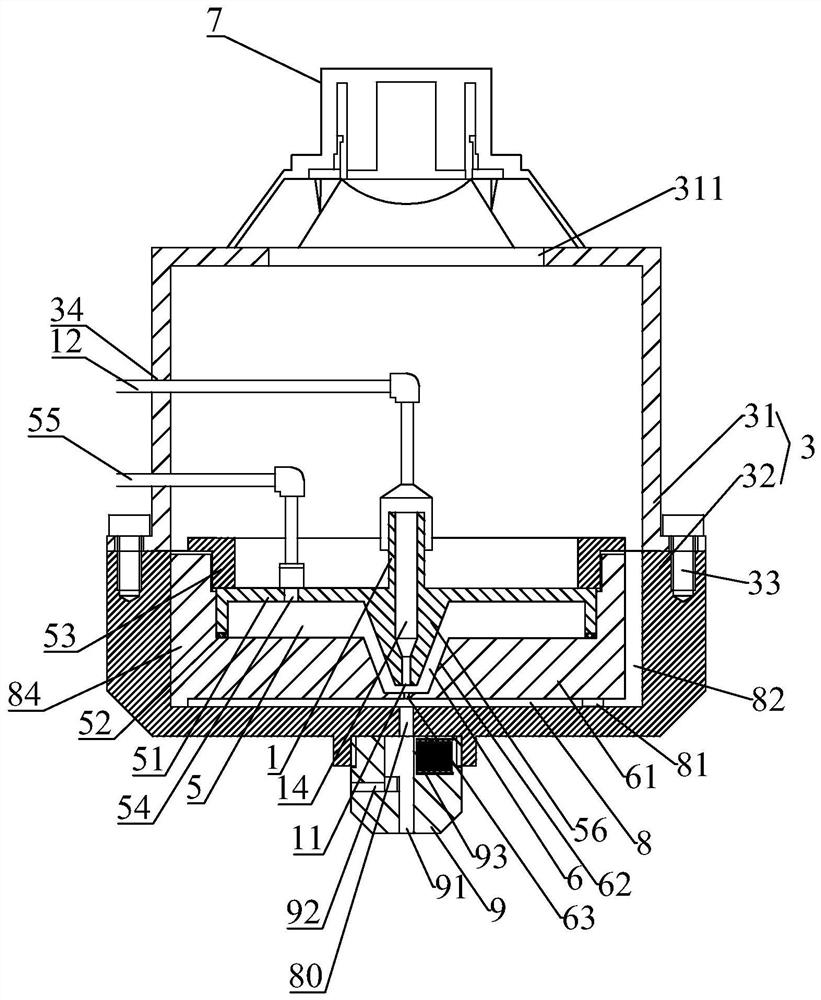

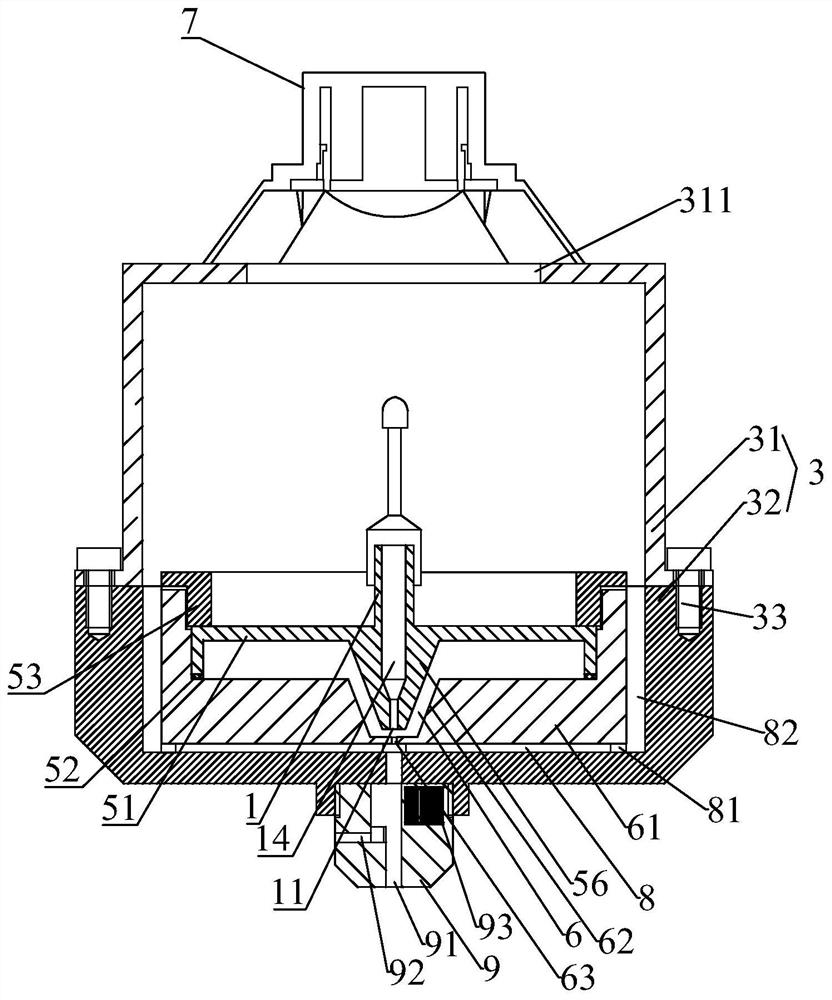

[0030] The present invention discloses an acoustophoretic composite flow focusing micro-nano jet printing device, such as Figure 1-3 As shown, it is a preferred embodiment of the present invention, such as figure 1 As shown, the micro-nano jet printing device includes an inner nozzle 1 communicated with a jet printing fluid supply device 41 and a flow focusing assembly and an acoustophoretic focusing assembly distributed outside the inner nozzle 1. The inner nozzle 1 is provided with a liquid outlet 11, and the outlet Below the liquid port 11, there is a substrate 2 for receiving the printing droplets; the printing fluid is output from the liquid outlet 11, and the flow focusing component first performs flow focusing on it, so that the printing fluid is aggregated to form a slender micro-jet, and the micro-jet is in the After fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com