A preparation method of a shape support device for processing military figurines

A support device and shape technology, which is applied in the field of preparation of shape support devices for processing military figurines, can solve the problems of the influence of steel wire mesh shape, troublesome construction process, and difficulty in manufacturing military figurines, so as to reduce the difficulty of shaping and ensure installation The effect of stability and precise docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

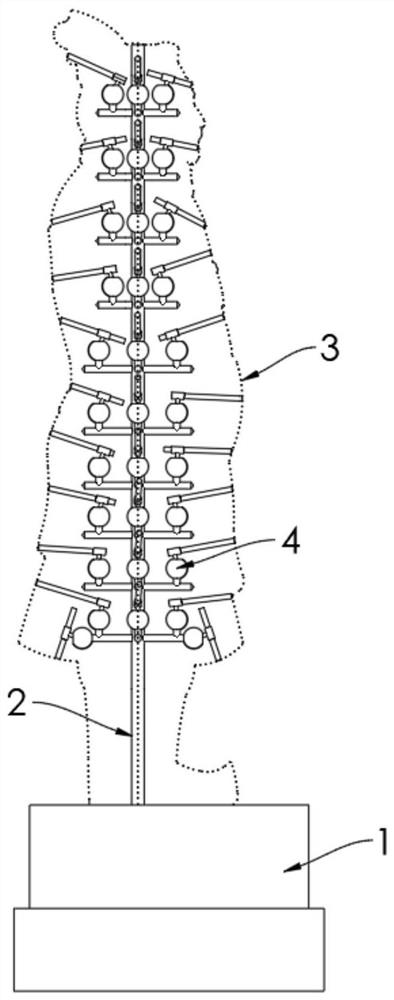

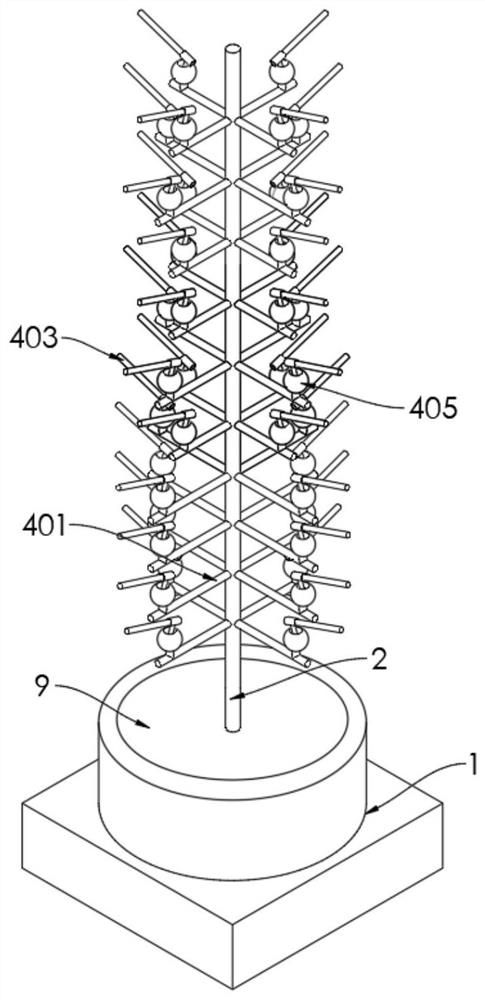

[0038] refer to Figure 1-6 , a shape support device for processing military figurines, comprising

[0039]Base 1, the middle of the base 1 is affixed with a support rod 2 upwards, and four corresponding molding rods 3 are affixed upward at an equal angle of 90° on the base 1, and the bottom of the molding rod 3 fixed on the base 1, and the tops of the molding rods 3 are respectively fixed on the top ends of the supporting rods 2;

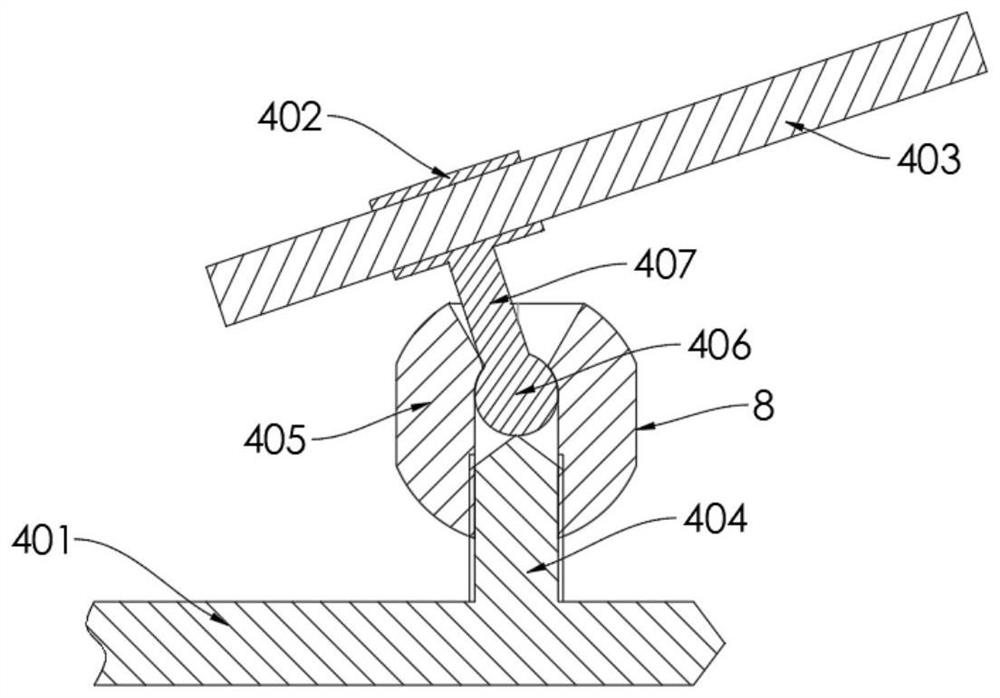

[0040] The support mechanism 4 includes four rows of horizontal support rods 401 fixed side by side on the support rods 2 at equal angles. The outer ends of the lateral support rods 401 are respectively located inside the corresponding molding rods 3. Corresponding installation pipes 402 are installed on the rods 401 with adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com