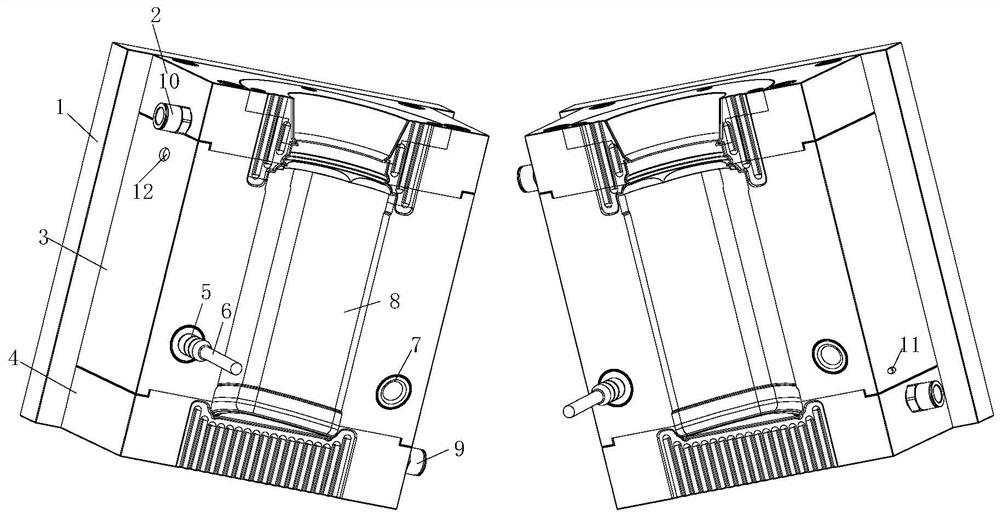

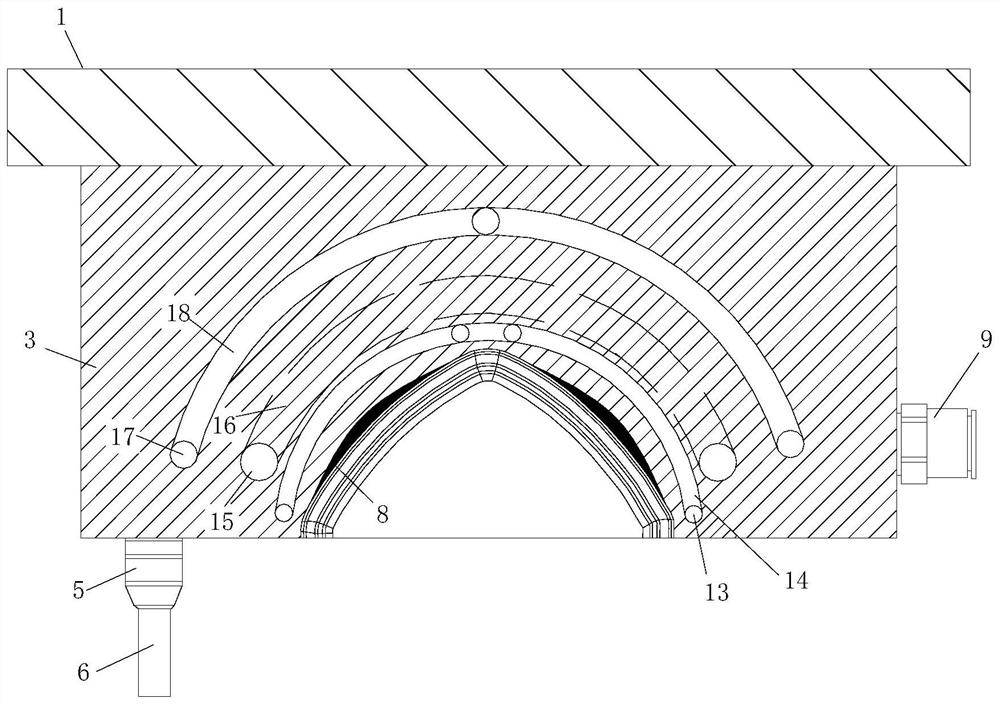

PET bottle preform mold

A mold and preform technology, applied in the field of molds, can solve problems such as uneven wall thickness and difficulty in shaping the bottle body, and achieve the effects of uniform wall thickness of the bottle body, improved quality, and accelerated cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

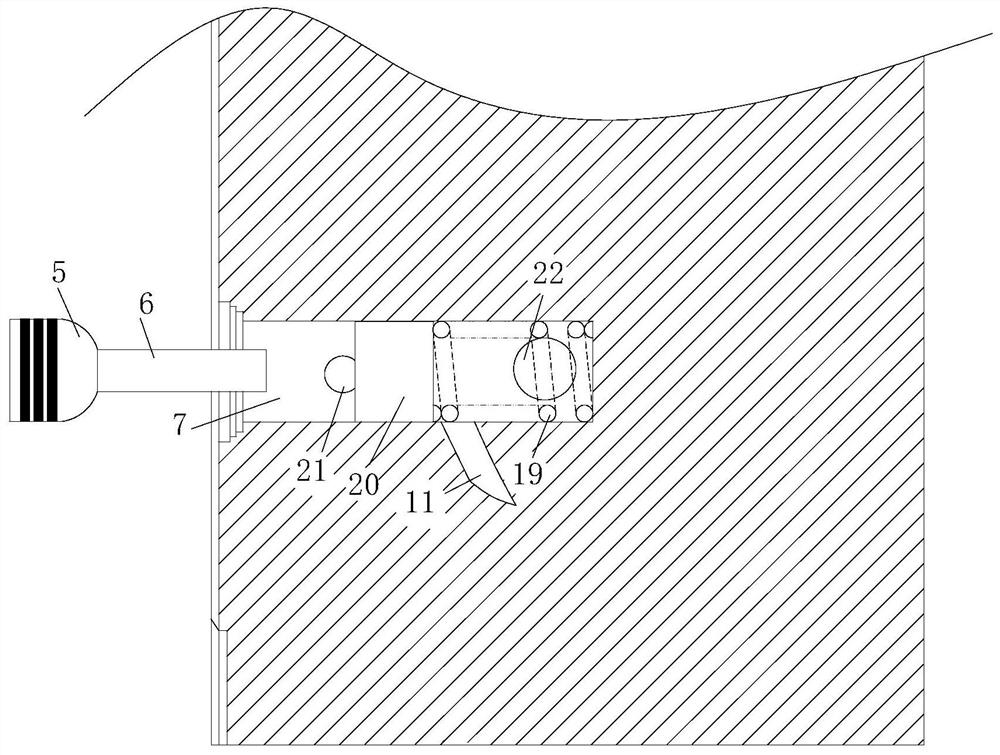

[0028] As an embodiment of the present invention, multiple groups of throat pipes 23 with inner diameters smaller at the top and larger at the bottom are arranged in the first passage 13, and a passage connecting the mold cavity and the first passage 13 is provided at the throat pipe 23. Air gap 24. In the first channel 13, multiple groups of throat pipes 23 with a small upper diameter and a larger lower diameter are arranged, so that the air flow can generate negative pressure in the throat pipes 23, so that when high-pressure air is introduced into the first passage 13, the pressure in the mold cavity The air can be drawn out quickly to avoid the quality problems of flat body, collapsed shoulders, depressions and unclear patterns of square bottle preforms caused by the difficult discharge of gas inside the mold cavity at the initial stage of blow molding, thus improving the quality of blow molding.

[0029] As an embodiment of the present invention, the front ends of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com