Variable-spacing battery cell taking and placing device

A pick-and-place device and battery cell technology, which can be used in battery assembly, transportation and packaging, climate sustainability, etc., can solve the problems of inapplicability of the variable distance mechanism, achieve simple structure, low cost of control and maintenance, and avoid The effect of error accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

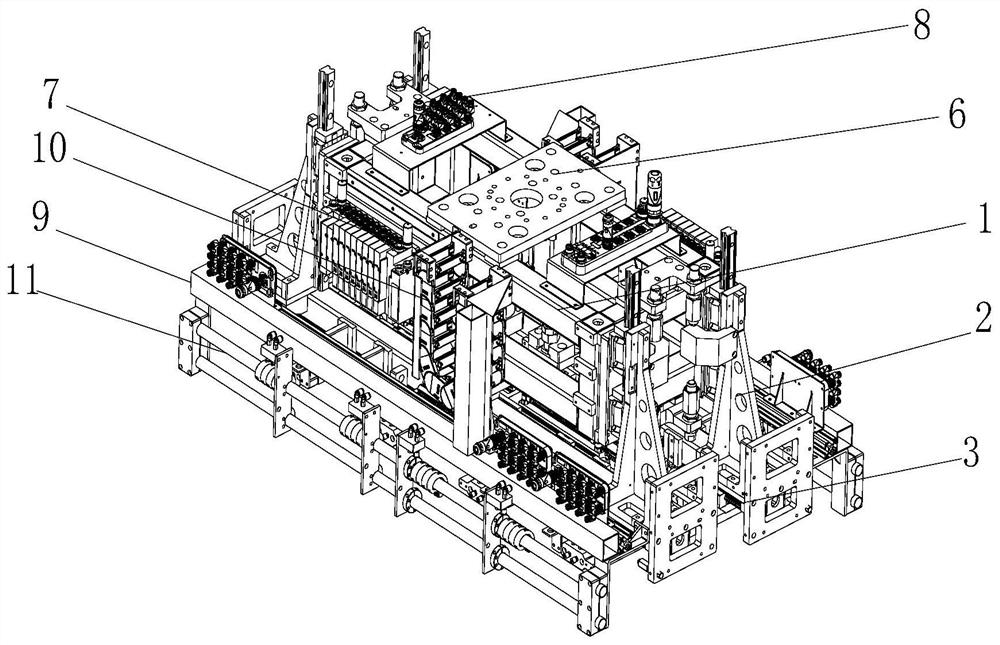

[0041] refer to Figure 1-Figure 3 As shown, the variable pitch cell pick-and-place device of this embodiment includes:

[0042] Mounting bracket 1;

[0043] The lifting frame 2 is arranged on the installation bracket 1 and slides along the height extension direction of the installation bracket 1;

[0044] The slide rail 3 is arranged on the lifting frame 2 and slides up and down with the lifting frame 2;

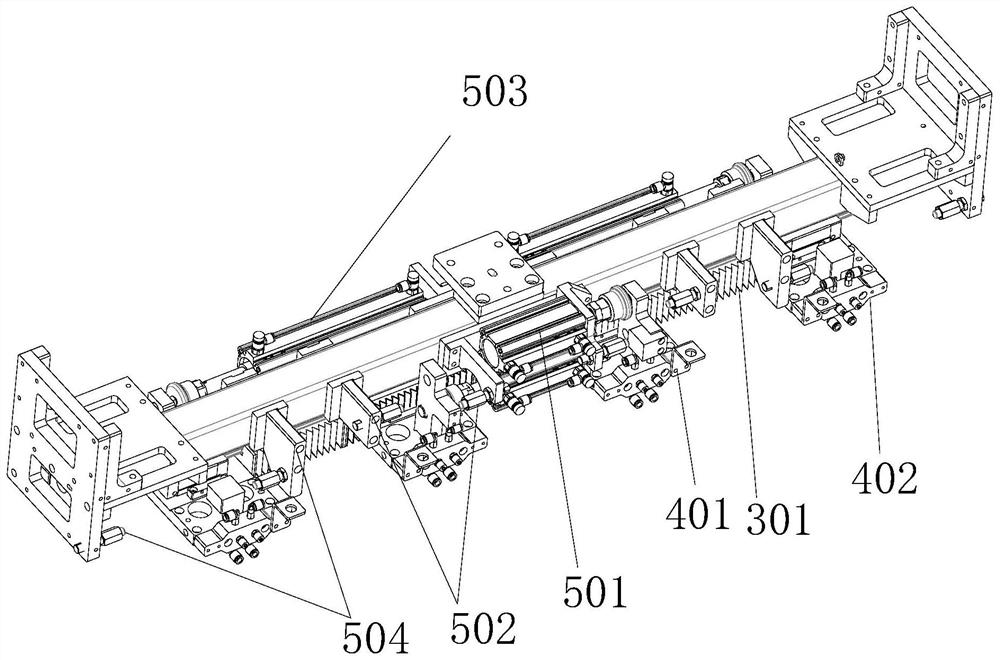

[0045] The cell gripper 4 is used to grab the cell, including two middle cell grippers 401 slidably arranged at the center of the slide rail and side cell grippers 402 arranged on both sides of the middle cell gripper ;

[0046] Distance changing mechanism 5, described distance changing mechanism 5 comprises:

[0047] The short variable distance driving source 501 is arranged at the center of the two middle cell grippers 401, and pushes the two middle cell grippers 401 to move on the slide rail;

[0048] The first limiting member 502 includes two first limiting blocks ...

Embodiment 2

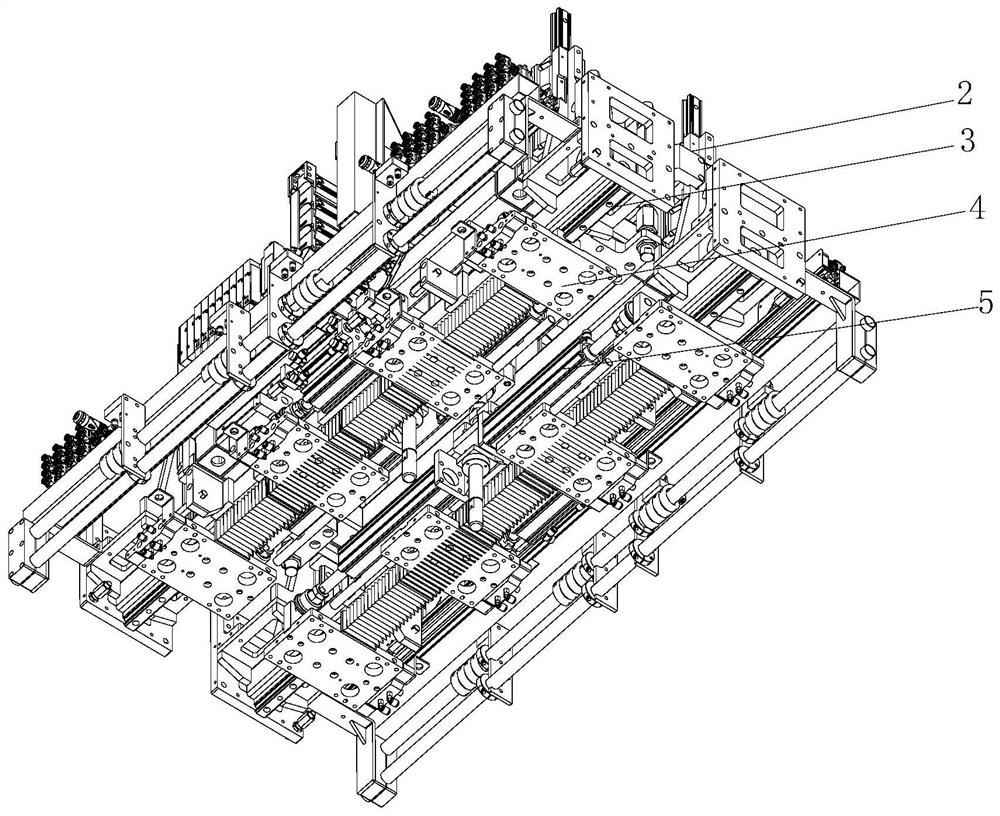

[0069] refer to Figure 5 As shown, the variable-pitch battery pick-and-place device of this embodiment includes: the installation bracket 1 in the above-mentioned embodiment 1, the lifting frame 2, the slide rail 3, the battery clamp jaw 4, the pitch-changing mechanism 5, and the installation adapter plate 6. The valve island 7, the remote IO communication module 8, the trunking 9, the tank chain 10, and the battery gripper wire pipe 11 can realize all the actions and functions of the above-mentioned embodiments. On this basis, considering the In the process of changing the distance of the battery cell, the problem of the battery core falling off occurs. In this embodiment, a bottom mechanism 12 is also provided. The bottom mechanism 12 is arranged on the lifting frame 2 and moves up and down together with the lifting frame 2 , can always maintain the relative position with the cell gripper 4, the pocket bottom mechanism 12 includes an anti-fall bar 1201 and a pocket drive so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com