AGV for intelligent manufacturing production line

An intelligent manufacturing and production line technology, applied in the direction of lifting devices, etc., can solve problems such as unstable center of gravity, dumping of the car body, and poor stability, so as to avoid tipping and rollover, maintain stability, and have good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

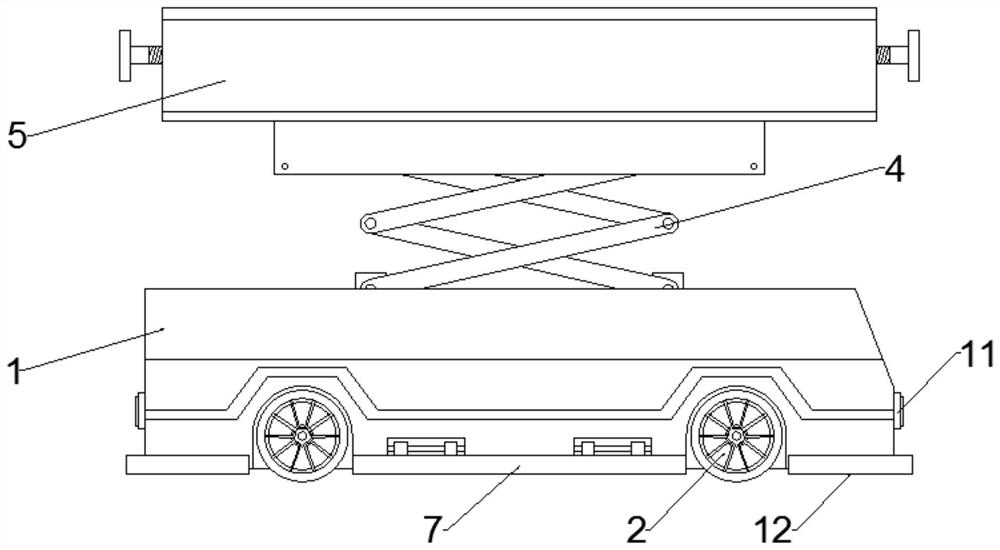

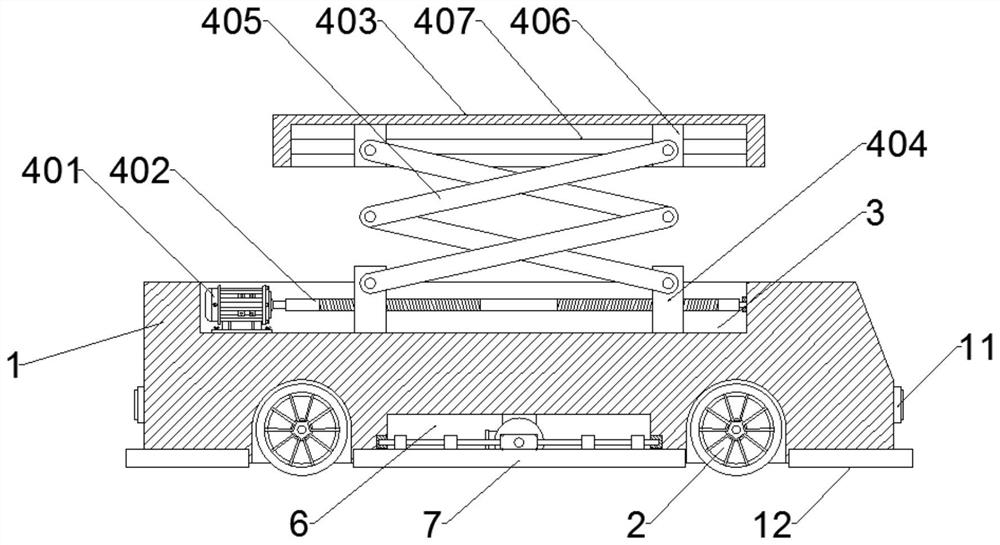

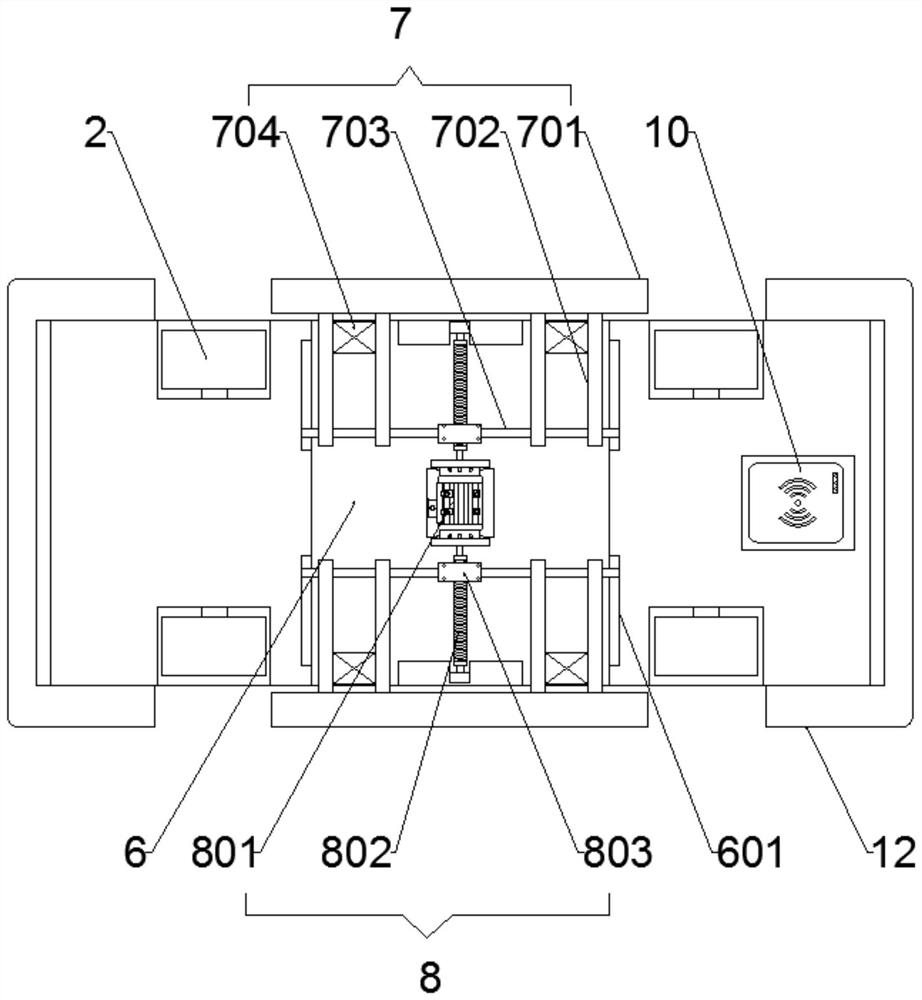

[0025] Such as figure 1 As shown, the present invention provides an anti-dumping AGV car with adjustable shelf positions for intelligent manufacturing production lines, including a car body 1, wheels 2 are arranged at the bottom of the car body 1, and a first setting groove 3 is opened on the upper end of the car body 1. A lifting rod assembly 4 is arranged in the first setting groove 3, a cargo bucket 5 is installed on the top of the lifting rod assembly 4, and a second setting groove 6 is provided at the bottom of the car body 1, and a second setting groove 6 that can be deployed from the bottom of the car body 1 is arranged in the second setting groove 6 And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com