Fabricated building wall beam stable connection structure

A connecting structure and assembled technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of affecting the speed of assembly, prolonging the construction period, and troublesome installation, so as to improve the pressure bearing capacity, facilitate transportation, and save space. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

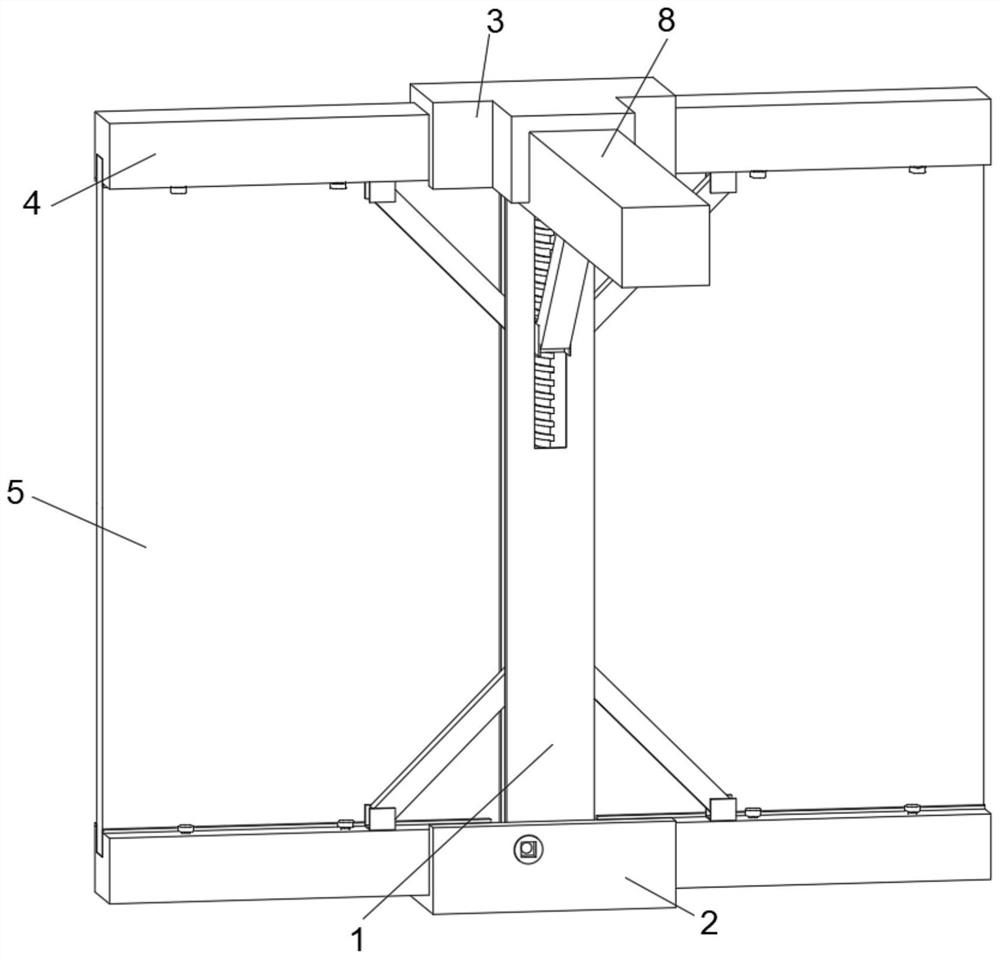

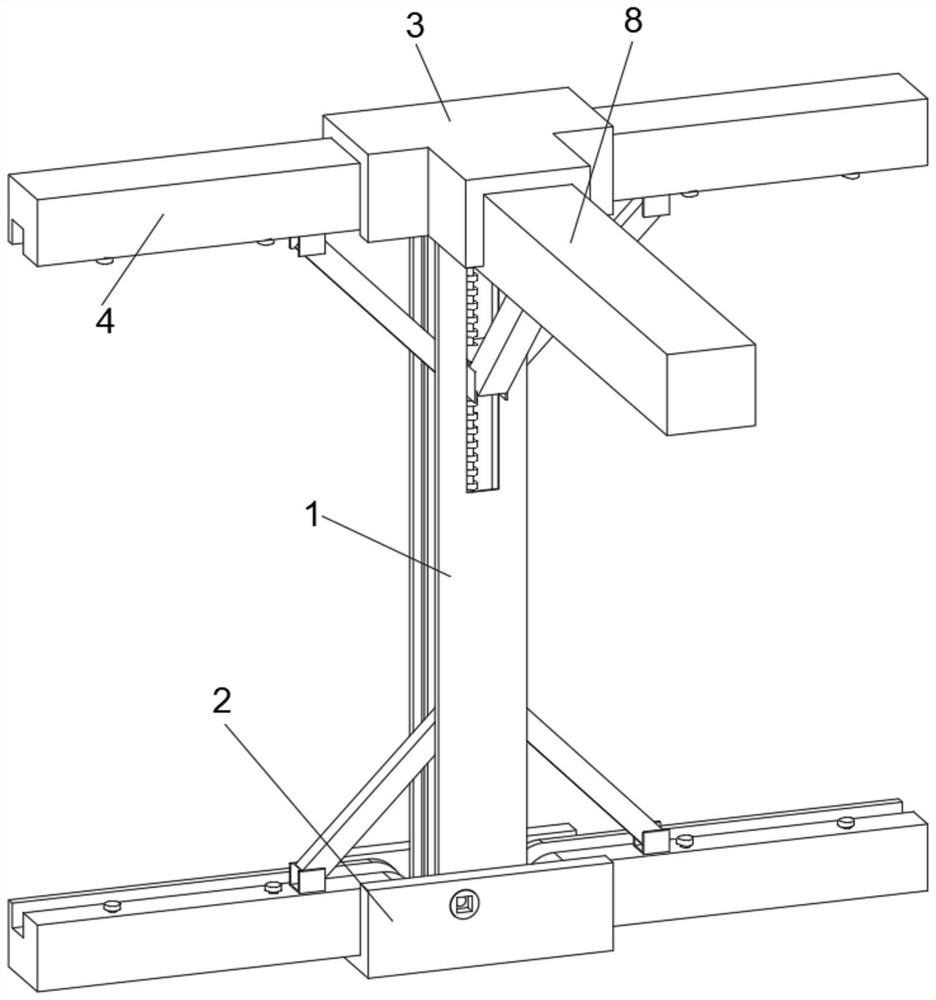

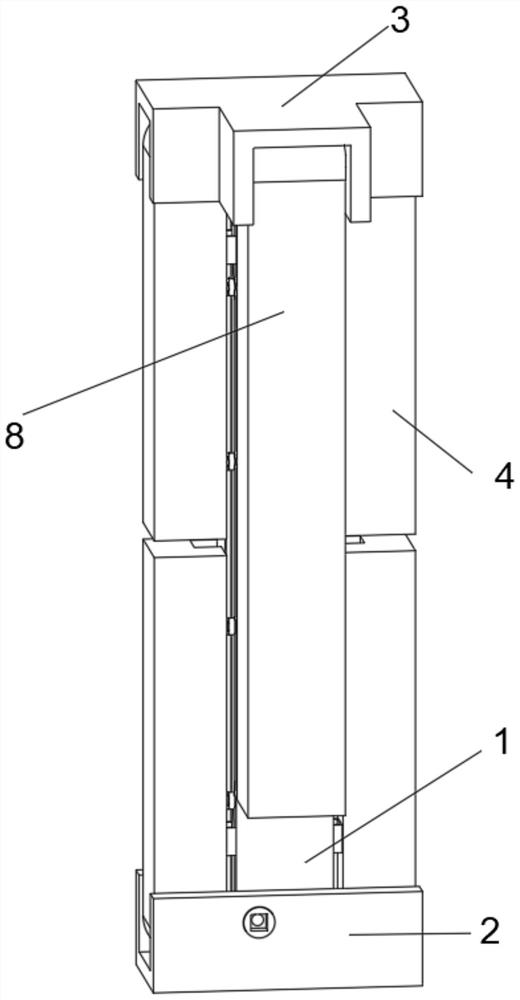

[0030] Please refer to Fig. 1-7, the present invention provides a kind of technical scheme:

[0031] A stable connection structure for prefabricated building wall beams, comprising a supporting column 1, the lower end of which is connected and fixed with a base 2, the top surface of the supporting column 1 is connected and fixed with a triangular seat 3, and the upper and lower ends of the supporting column 1 are hinged in a left-right symmetrical structure There are two beams A4, two wall panels 5 are installed symmetrically on the left and right sides of the support column 1, a placement groove 6 is opened on the upper end of the support column 1, and an auxiliary fixing component 7 is arranged in the placement groove 6, and a beam B8 is hinged on the lower side of the front end of the triangular seat 3 .

[0032] Specifically, the inside of the support column 1 is set in a hollow structure, the inner wall of the lower end of the support column 1 is rotatably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com