Detachable shell device of Coriolis force mass flow meter

A mass flow meter and Coriolis force technology, applied in the field of detachable housing devices, can solve the problems of incorrect position of the damping plate, time-consuming and laborious, and need to be disassembled from the pipeline and then disassembled for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

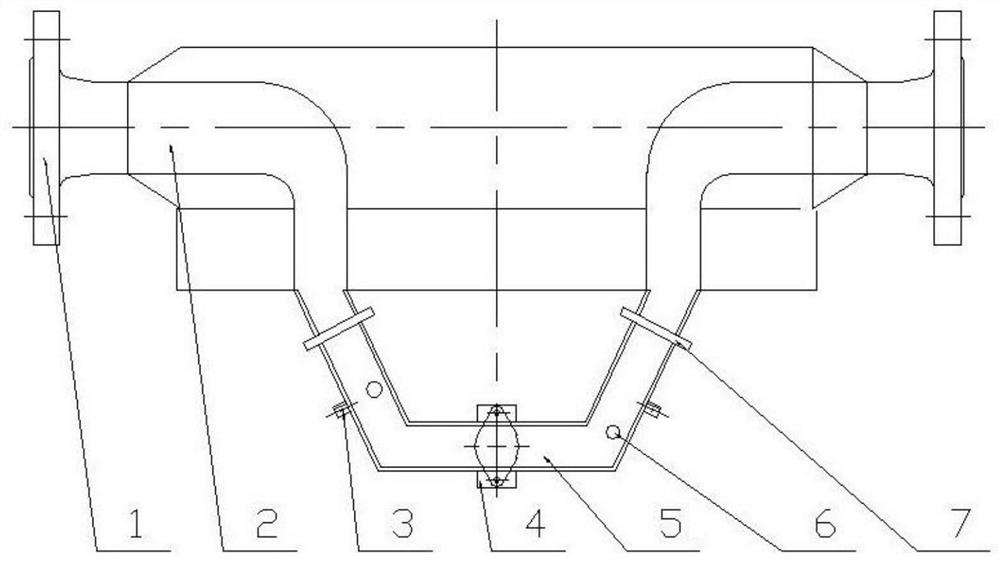

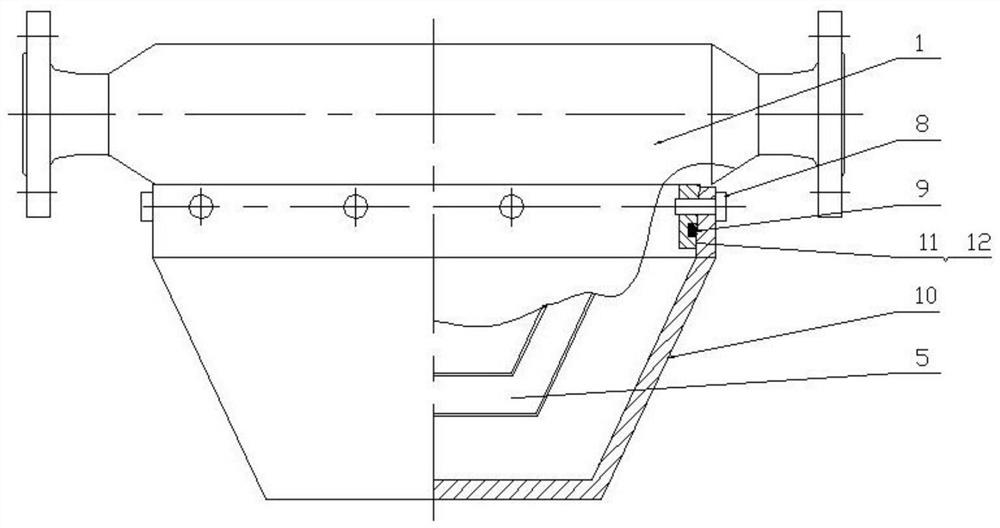

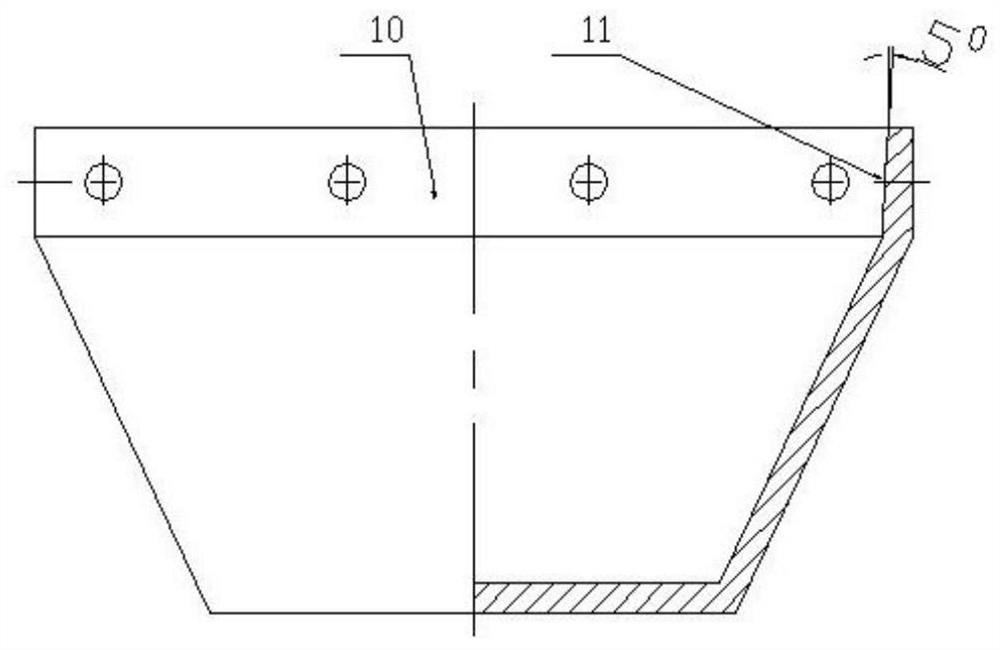

[0018] Such as figure 1 As shown, the Coriolis force mass flowmeter includes support tube 1, shunt fluid 2, detection coil 3, drive coil 4, flow measurement tube 5, counterweight 6, damping plate 7, connecting bolt 8, and sealing strip 9 . The detachable shell 10 , the detachable shell is connected to the sealing slope 11 , the support tube is connected to the sealing slope 12 , and the sealing groove 13 .

[0019] Such as Figure 2 to Figure 5 As shown, the detachable casing device of the present invention is mainly composed of a detachable casing 10 , a support tube 1 , connecting bolts 8 , and a sealing strip 9 . The original closed shell directly welded on the support tube 1 is no longer connected by welding process, but on the outer surface of the lower part of the support tube 1 and the inner surface of the opening of the detachable shell 10, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com