Detection system for analyzing one or more particles

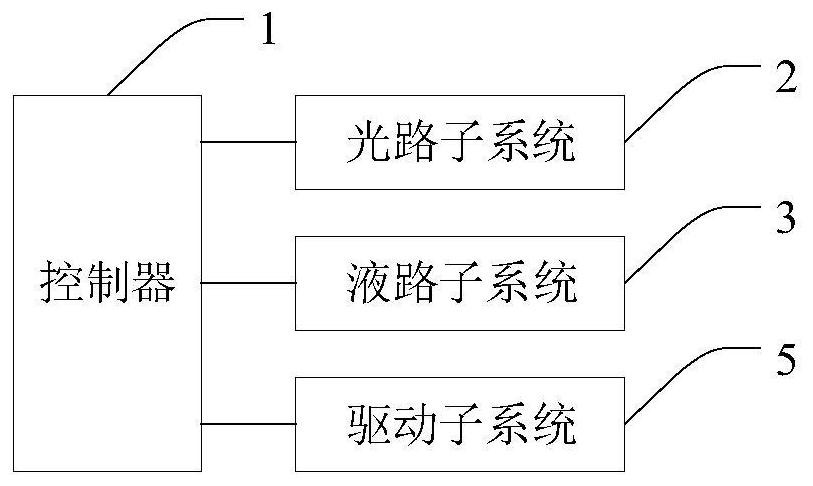

A detection system and particle technology, which is used in the analysis of materials, material excitation analysis, material analysis by optical means, etc., can solve the problems of complex sample suction process, affecting the accuracy of detection results, cleaning sample probes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Embodiment one ( Image 6The embodiment of the liquid circuit subsystem shown), in this embodiment, in Figure 5 On the basis of the shown liquid circuit subsystem, the liquid circuit subsystem is added with a first gating device 34 . In this embodiment, the first gating device 34 has an outlet 1 , an inlet 2 and a liquid outlet 3 . The first gating device 34 gates the detection chamber 33, the sampling needle a and the drain port 3, specifically, it is used to connect the outlet 1 with the inlet 2 after switching; and connect the outlet 1 to the drain port 3 after switching. connected. The outlet 1 of the first gating device 34 is directly connected to the inlet of the detection chamber 33 or connected to the inlet of the detection chamber 33 through a tube, and the inlet 2 of the first gating device 34 is connected to the sampling needle a. The liquid discharge port 3 of the first gating device 34 is used to discharge liquid toward the waste liquid recovery device ...

Embodiment 2

[0116] Embodiment two ( Figure 7 The embodiment of the liquid circuit subsystem shown), in this embodiment, in Figure 5 On the basis of the fluid path subsystem, the fluid path subsystem adds a second gating device 32 . The first fluid power source 31 is sequentially connected to the outlet of the detection chamber 33 through the first pipeline g1 and the second gating device 32 . The second gating device 32 has a liquid discharge port for discharging liquid toward the waste liquid recovery device 38 . The liquid discharge port can directly discharge liquid to the waste liquid recovery device 38 , or connect to the waste liquid recovery device 38 through the third pipe g3 , and discharge liquid to the waste liquid recovery device 38 through the third pipe g3 . The third pipe g3 can be various types of pipes, as long as it can discharge liquid, it is not limited in the present invention.

[0117] In this embodiment, the second gating device 32 is used for gating the first ...

Embodiment 3

[0124] Embodiment three ( Figure 8 The embodiment of the liquid circuit subsystem shown), this embodiment is equivalent to the Figure 5 On the basis of above, the first fluid power source 31 is changed from bidirectional to unidirectional, and the first fluid power source 31 has an inlet and a liquid discharge port, and the liquid discharge port is used for discharging liquid toward the waste liquid recovery device 38 . In this embodiment, as indicated by the arrow, the flow direction of the liquid is unidirectional. For example, the first fluid power source 31 may use a unidirectional pump to realize the unidirectional flow of the liquid. The inlet of the first fluid power source 31 can be directly connected to the outlet of the detection chamber 33 , or can be connected to the outlet of the detection chamber 33 through the first pipeline g1 . The inlet of the detection chamber 33 may be directly connected to the sampling needle a, or may be connected to the sampling needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com