Blended ore tracking judgment method and system

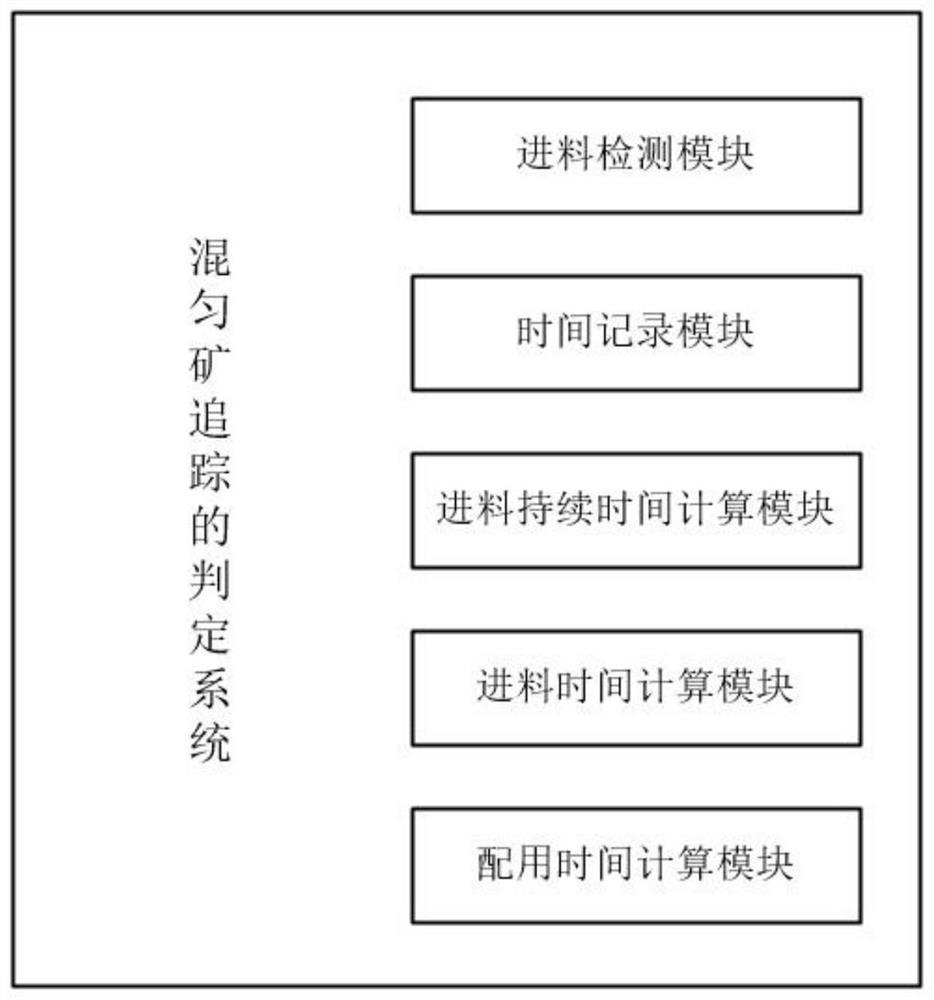

A judging method and judging system technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as delays, and achieve accurate tracking results and accurate material ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiment of the present application solves the technical problem in the prior art that the tracking result of the feeding time of the mixed ore is delayed by providing a method for judging the mixed ore tracking.

[0047] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

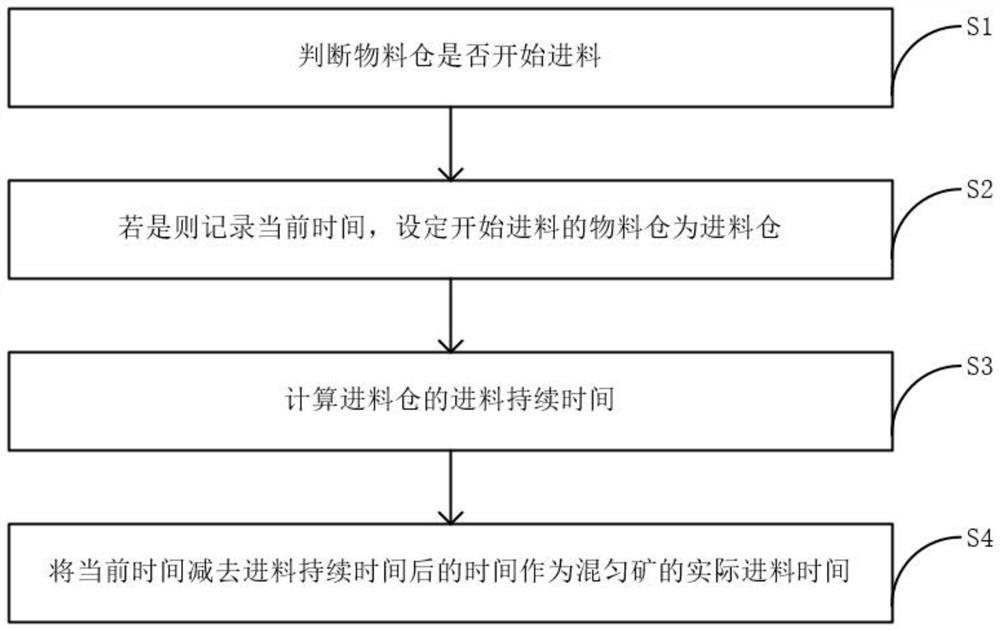

[0048] A method for judging mixed ore tracking, comprising:

[0049] Determine whether the material bin starts to feed;

[0050] If so, record the current time, and set the material bin that starts feeding as the feeding bin;

[0051] calculating a feed duration for said feed bin;

[0052] The time obtained by subtracting the feeding duration from the current time is taken as the actual feeding time of the mixed ore.

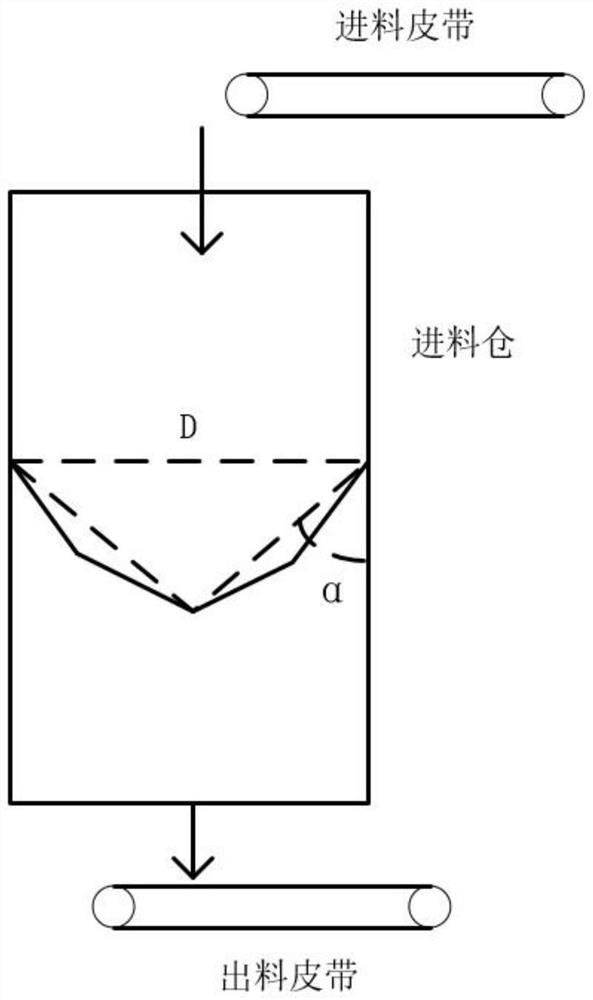

[0053] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com