Amplification structure of double-lens focusing ultrasonic transducer

A technology of focusing ultrasound and transducers, applied in the field of ultrasound, can solve problems such as operator inconvenience, achieve the effects of prolonging service life, improving sound radiation efficiency, and reducing excessive center deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

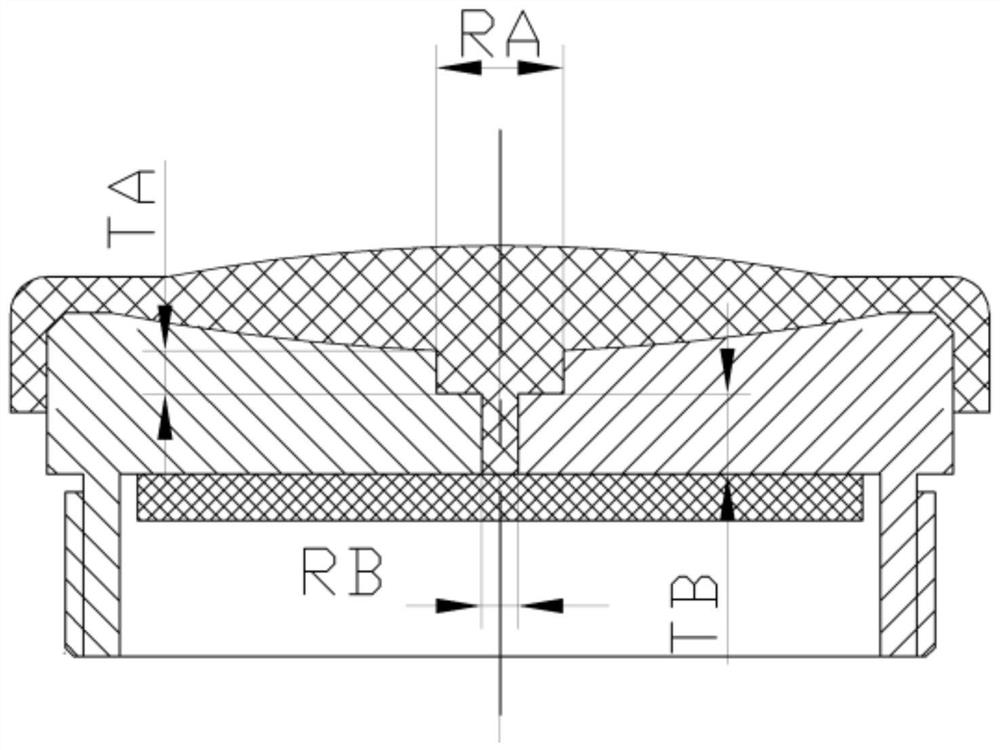

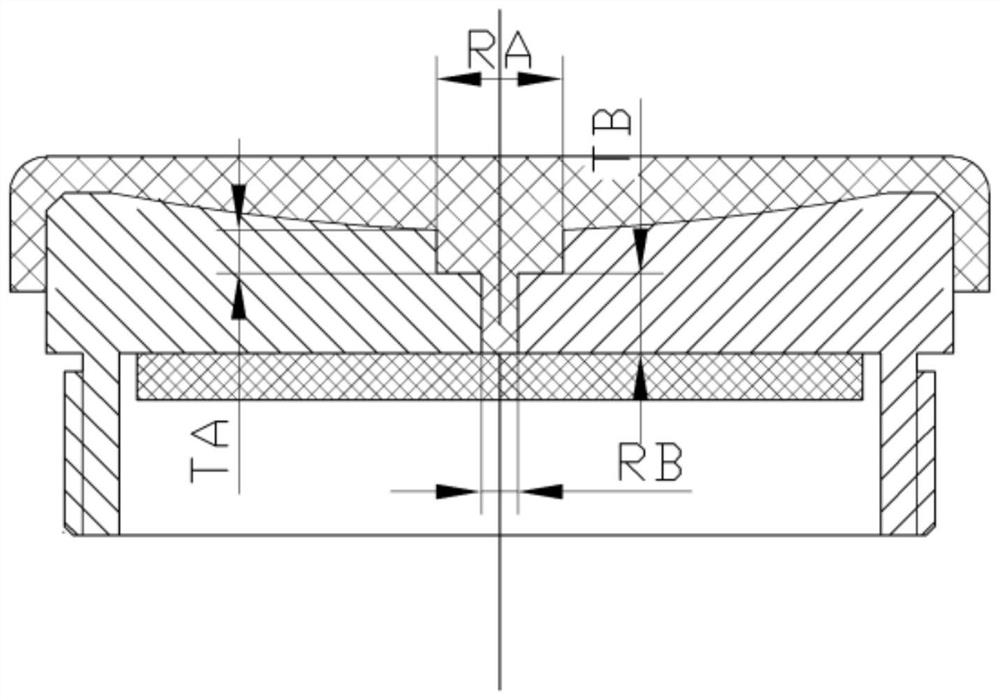

[0020] See figure 1 and figure 2 , the present invention provides a dual-lens focusing ultrasonic transducer amplification structure, which has a low-sonic material acoustic lens 1, a high-sonic material acoustic lens 2, a piezoelectric ceramic sheet 3, and the piezoelectric ceramic sheet 3 is connected to the piezoelectric ceramic sheet 3 The low-sonic material acoustic lens 1 is connected to the high-sonic material acoustic lens 2, and the center of the sound axis of the low-sonic material acoustic lens 1 is provided with a second-order ladder structure 4 connected to the high-sonic material acoustic lens 2, and the second-order ladder structure 4 has Primary diameter RB, depth TB, secondary diameter RA, height TA. That is, the central hole of the concave spherical surface of the high-sonic material acoustic lens 2 provides an exhaust passage for the injection molding of the low-sonic material at the same time, and the low-sonic material is injected into the central hole o...

Embodiment 2

[0025] See figure 2 , the low sound velocity material acoustic lens 1 is a single convex spherical acoustic lens. According to the working frequency and radiation area of the focusing transducer, select the appropriate values of TB and RB in the second-order structure to improve the sound output efficiency. According to the working frequency and radiation area of the focusing transducer, select the appropriate values of TA, RA, TB and RB in the second-order structure to improve the sound output efficiency.

[0026] Specifically, the height TA=4.3mm, the second-order diameter RA=2.0mm, the depth TB=2.3mm, and the first-order diameter RB=7.0mm. The diameter of the radiating surface of the 800KHz focusing transducer is 50mm, and the focus position range is 50±10mm. It adopts a double-lens focusing mode, and the radius of curvature of the concave spherical surface is 100mm. The maximum sound pressure level of the sound axis is increased by at least 10dB.

Embodiment (3

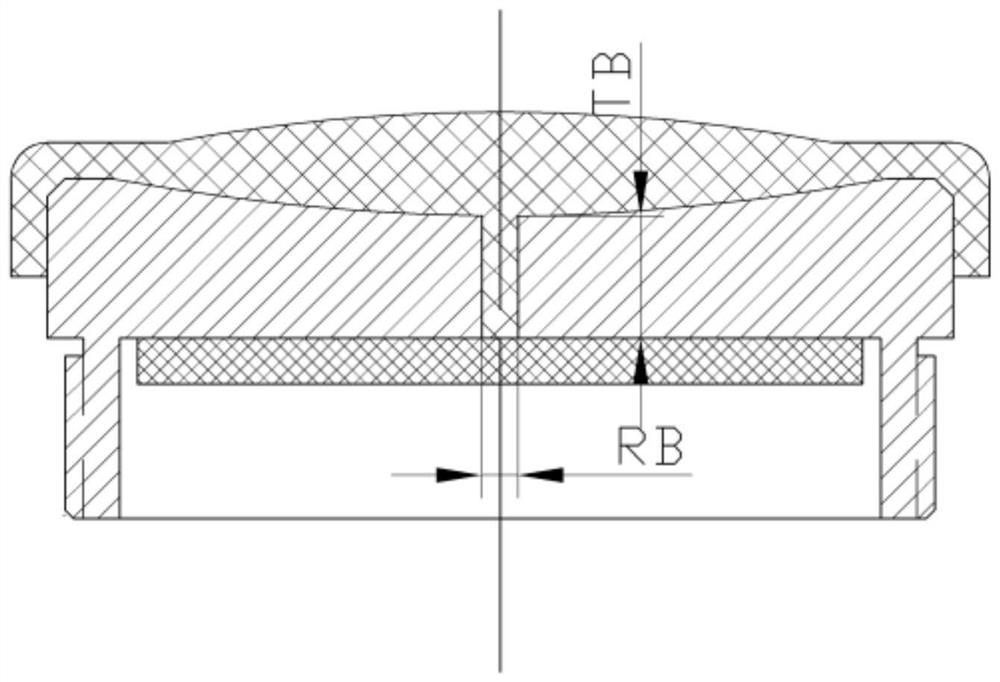

[0028] See image 3 , the low sound velocity material acoustic lens 1 is a biconvex spherical acoustic lens. According to the working frequency and radiation area of the focused transducer, select the appropriate values of TB and RB in the first-order structure to improve the sound output efficiency.

[0029] In the first-step ladder structure, the depth TB is a through hole, and the first-step diameter RB=2.0mm. The diameter of the 800KHz focusing transducer's radiation surface is 50mm, and the focus position range is 50±10mm. It adopts a double-lens focusing mode, and the radius of curvature of the concave spherical surface and the convex spherical surface is 100mm. The maximum sound pressure level of the sound axis is increased by at least 6dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com