Automatic rivet mounting method and device

An automatic installation and rivet technology, applied in transportation and packaging, household components, household appliances, etc., can solve the problems of inconsistent depth of multiple rivets, affecting product service life, time-consuming and laborious, and achieving wide applicability and improving installation efficiency. , to ensure the effect of consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

[0044] The invention provides an automatic installation method for rivets, comprising:

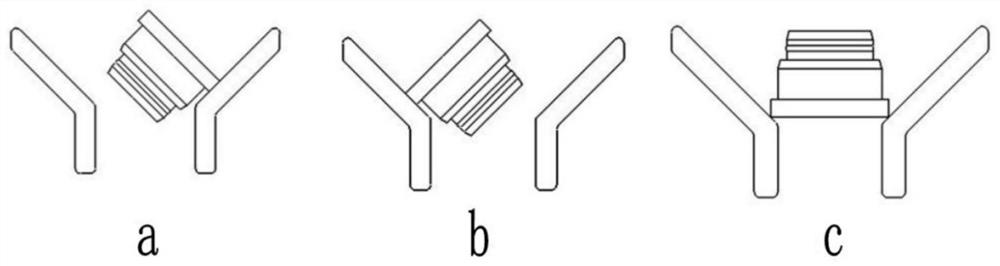

[0045]S1. Correcting the attitude of the target rivets on the track and not in the pre-installed state to the pre-installed state, and the target rivets are transported to the guide position by the track in the pre-installed state;

[0046] S2. Remove the target rivet located at the guiding position from the track, and move the target rivet to a pre-installed position;

[0047] S3. Using the indenter to press the target rivet at the pre-installation position, so that the target rivet is pressed into the pre-installation position to a predetermined depth.

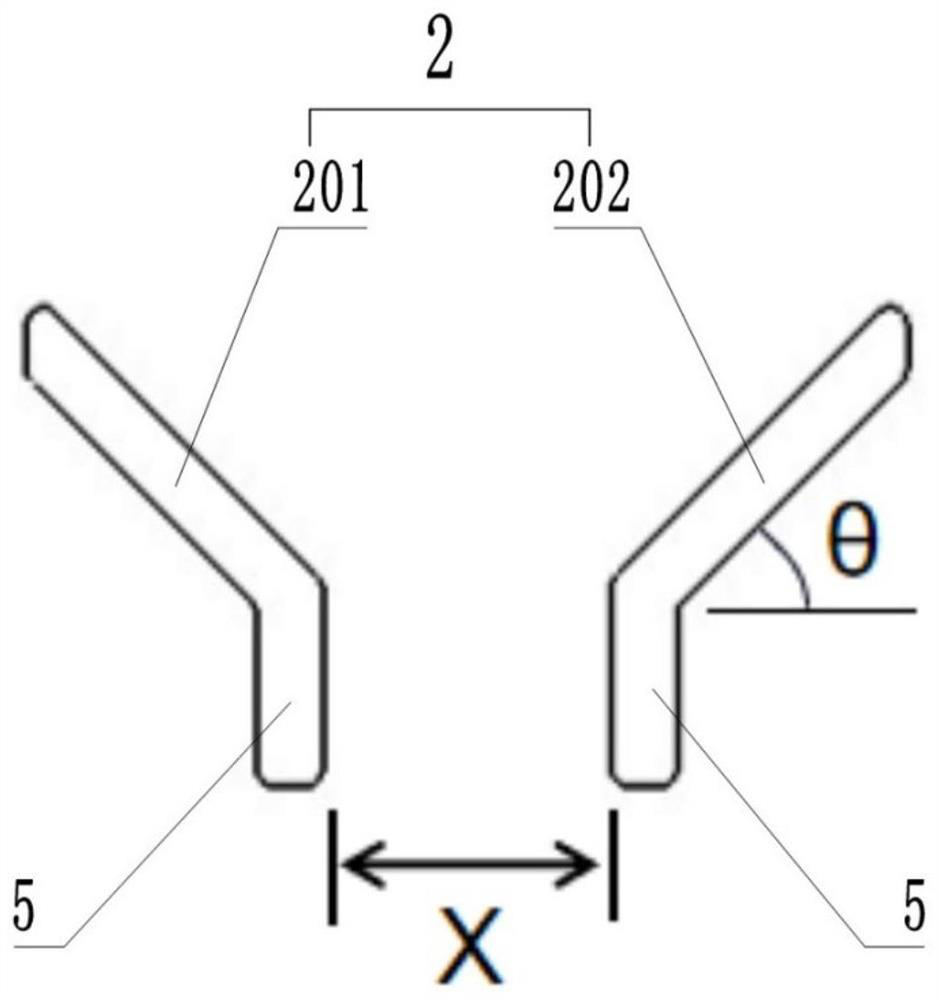

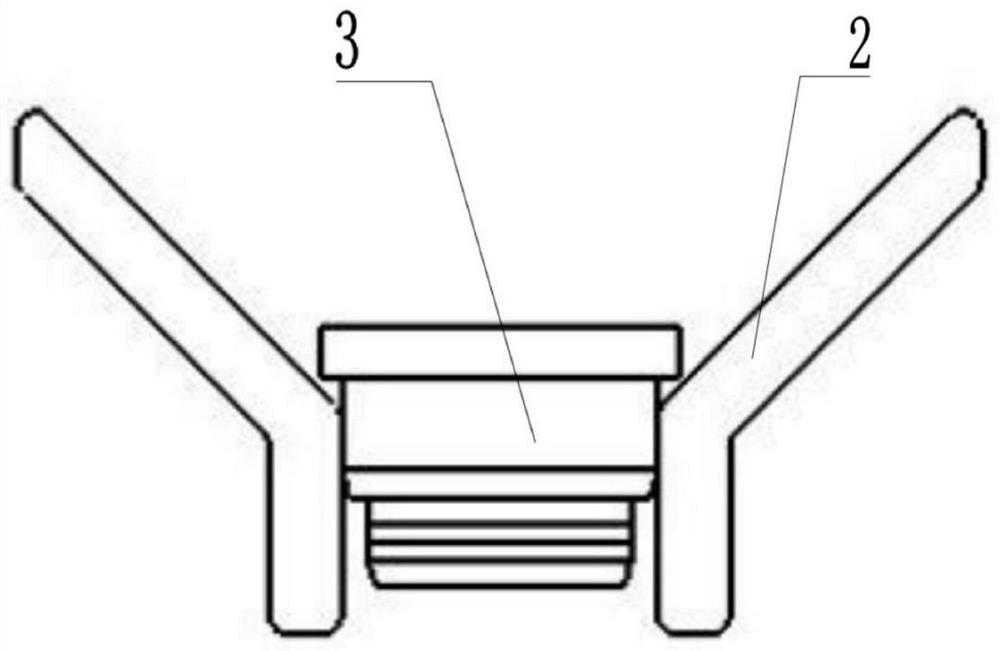

[0048] It should be noted that, if figure 2 As shown, it shows a schematic diagram of the structure of the rivet 3 in a pre-installed state, the central axis of the rivet 3 is kept parallel to the central axis of the track 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com