Frequency-adjustable sound absorption and insulation light composite board and manufacturing method

A lightweight composite board, sound absorption and insulation technology, applied in the field of vibration reduction and noise reduction, can solve problems affecting the effect of sound absorption and insulation, achieve the effects of suppressing resonance and matching effects, and facilitating processing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

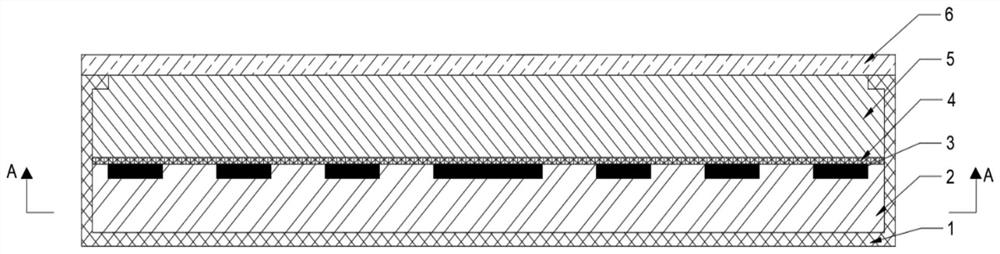

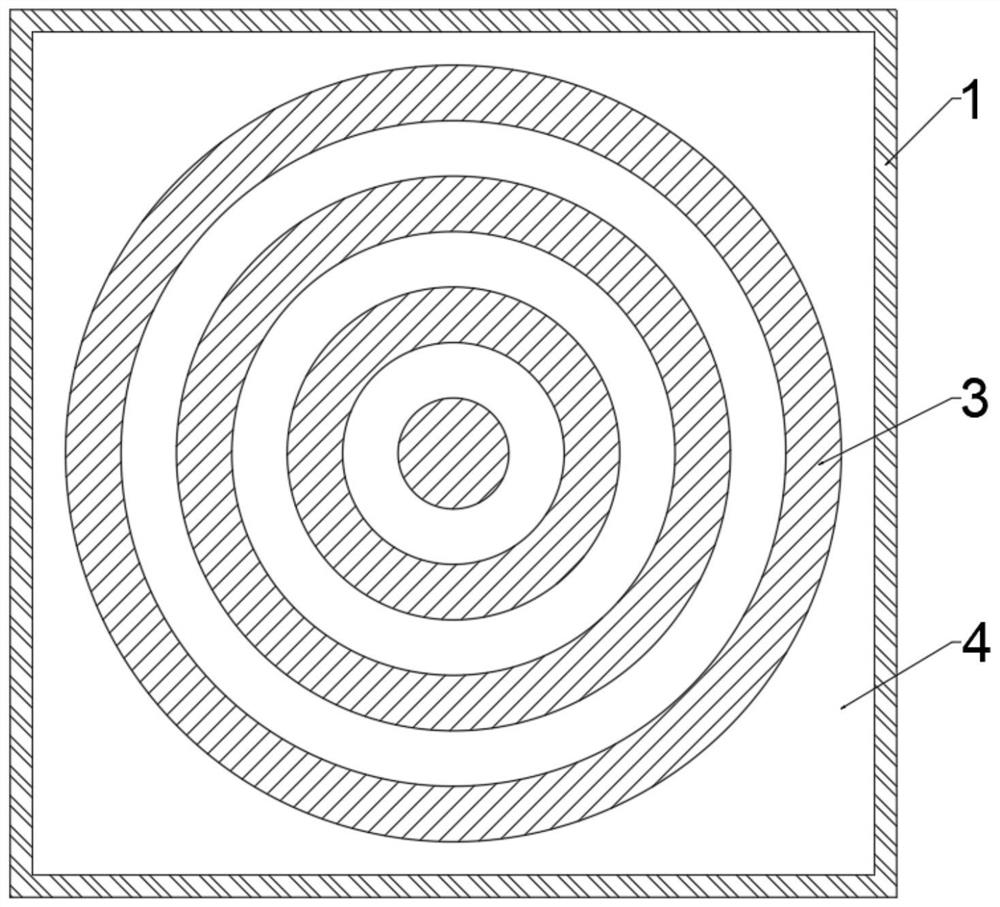

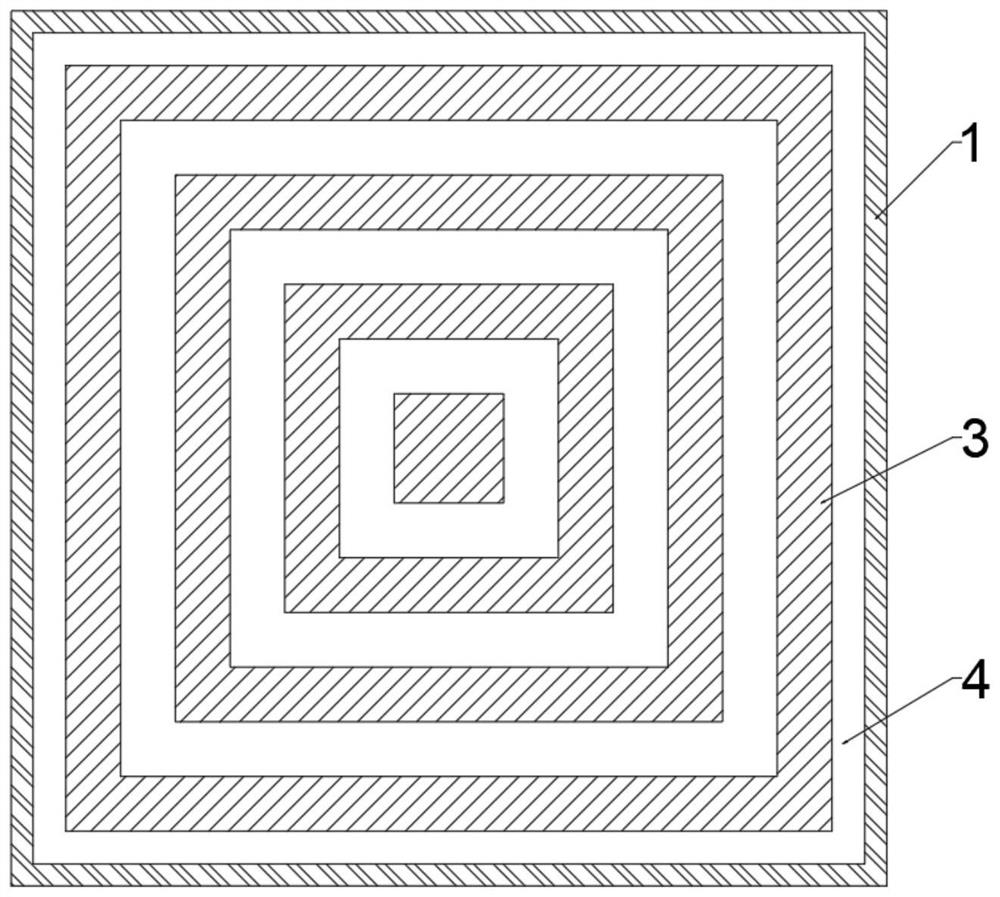

[0038] as attached figure 1 , figure 2 and image 3 As shown, a sound-absorbing and insulating lightweight composite panel with adjustable frequency is composed of a perforated plate 1, a sound-absorbing layer 2, a damping layer 3, a middle thin plate 4, a sound-insulating layer 5 and a sound-insulating plate 6 which are closely attached in sequence. The perforated plate 1 is made of a perforated aluminum plate into an open box-shaped body with a frame. In the box-shaped body, the sound-absorbing layer 2, the damping layer 3, the middle thin plate 4, and the sound-insulating layer 5 are successively placed, wherein the damping layer 3 The center of the circle is ( figure 2 ) or square ( image 3 ), and the circle or square is arranged with 3 rings or square rings at equal intervals outward and bonded to the surface of the middle thin plate 4 . The frame of the perforated plate 1 and the sound insulation plate 6 are riveted with rivets.

[0039] The perforated plate 1 is...

Embodiment 2

[0044] as attached figure 1 and Figure 4As shown, a sound-absorbing and insulating lightweight composite panel with adjustable frequency is composed of a perforated plate 1, a sound-absorbing layer 2, a damping layer 3, a middle thin plate 4, a sound-insulating layer 5 and a sound-insulating plate 6 which are closely attached in sequence. The perforated plate 1 is made of a perforated aluminum plate into an open box-shaped body with a frame, and the sound-absorbing layer 2, the damping layer 3, the middle thin plate 4, and the sound-insulating layer 5 are placed close to each other in the box-shaped body, wherein the damping layer 3 The arrangement of rectangular damping strips arranged at equal intervals is bonded to the surface of the middle thin plate 4 . The frame of the perforated plate 1 and the sound insulation plate 6 are riveted with rivets.

[0045] The perforated plate 1 is a perforated aluminum plate of 1060mm*1060mm, wherein the plane size is 1000mm*1000mm, the...

Embodiment 3

[0050] as attached figure 1 and Figure 5 As shown, a sound-absorbing and insulating lightweight composite panel with adjustable frequency is composed of a perforated plate 1, a sound-absorbing layer 2, a damping layer 3, a middle thin plate 4, a sound-insulating layer 5 and a sound-insulating plate 6 which are closely attached in sequence. The perforated plate 1 is made of a perforated aluminum plate into an open box-shaped body with a frame, and the sound-absorbing layer 2, the damping layer 3, the middle thin plate 4, and the sound-insulating layer 5 are placed close to each other in the box-shaped body, wherein the damping layer 3 With the middle thin plate as the base body, the laying rate is 50%, and 9 square blocks arranged equidistantly are bonded to the surface of the middle thin plate 4 . The frame of the perforated plate 1 and the sound insulation plate 6 are riveted with rivets.

[0051] The perforated plate 1 is a perforated aluminum plate of 1060mm*1060mm, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com