Tape winding machine and winding method

A winding machine and wrapping technology, applied in the direction of winding strips, transportation and packaging, sending objects, etc., can solve the problems of affecting winding, deformation of high temperature resistant tape, high viscosity of high temperature resistant tape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

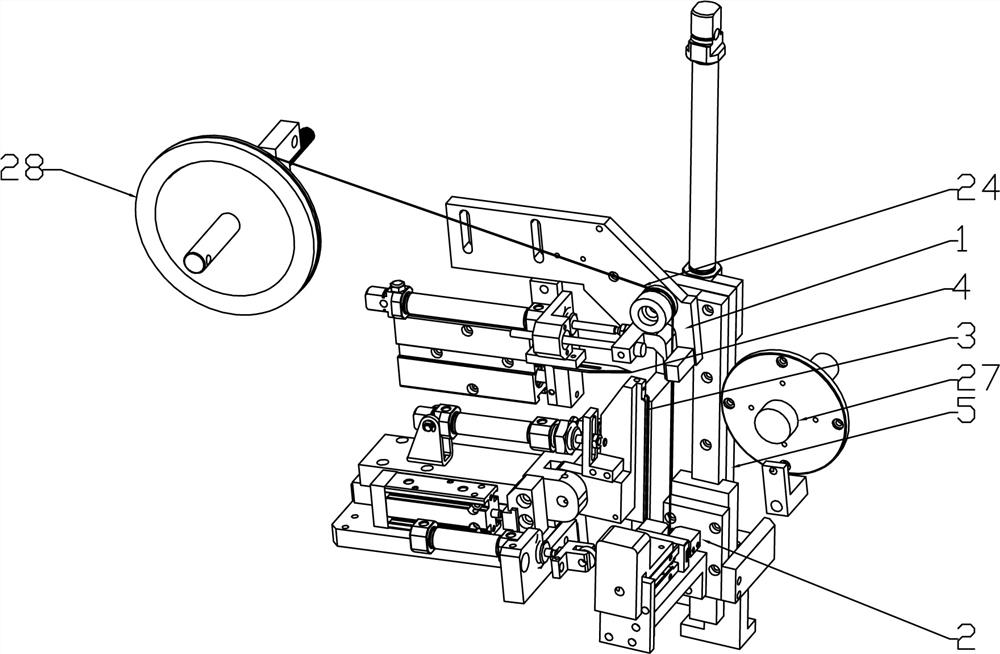

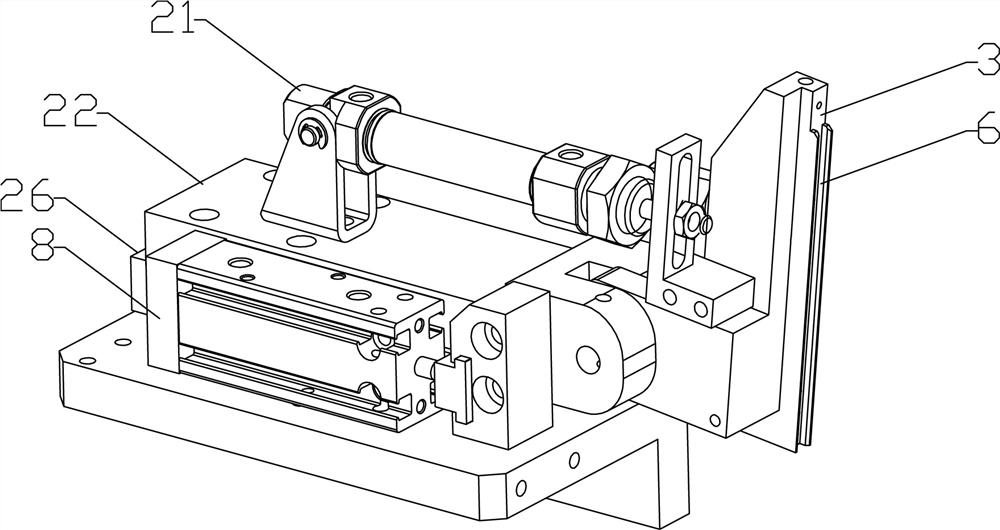

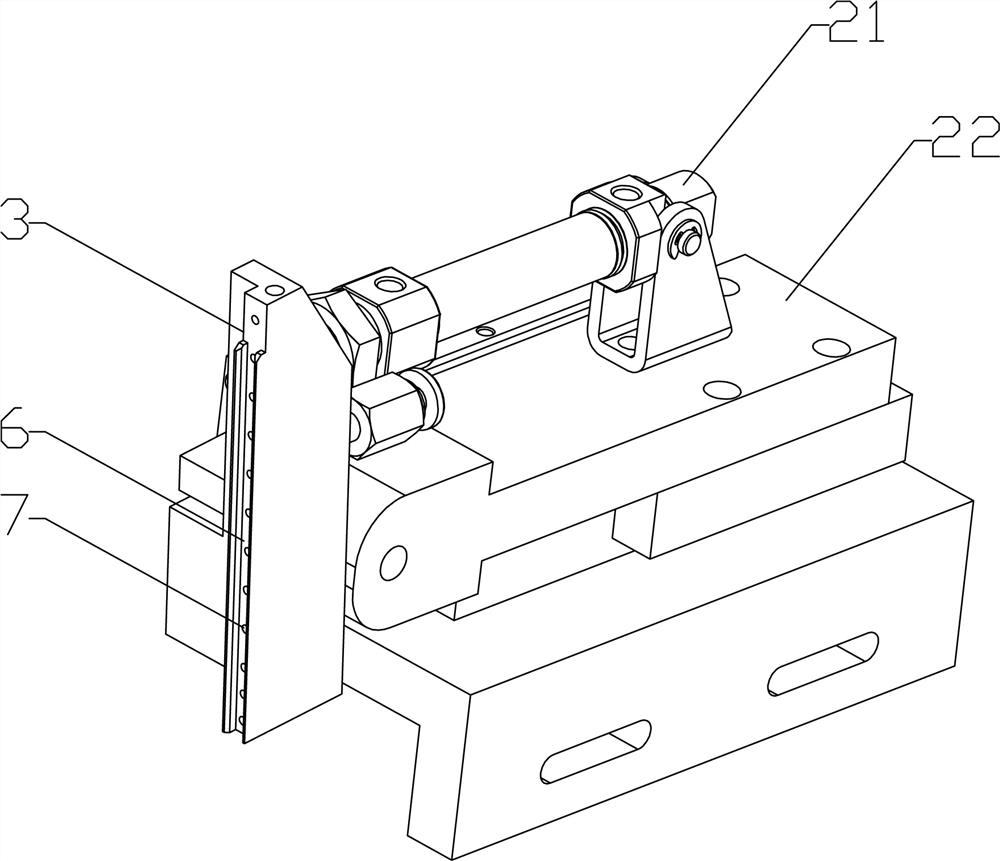

[0033] Such as Figure 1 to Figure 6 As shown, the tape winding machine of the present invention includes an upper clamping mechanism 1 , a lower clamping mechanism 2 , a negative pressure plate 3 and a blade 4 . The upper clamping mechanism 1 is arranged on the upper end of the frame 5 for clamping the adhesive tape 24 . The other end of the adhesive tape 24 is disposed on an adhesive tape reel 28 . The lower clamping mechanism 2 is arranged at the lower end of the frame 5 for clamping the lower end of the adhesive tape 24, and the lower clamping mechanism 2 can move up and down and rotate to one side, and the angle of rotation is ideally 20°- In the range of 60 °, and rotate to the opposite direction of adhesive tape 24 adhesive surface. The negative pressure plate 3 is arranged on one side between the upper clamping mechanism 1 and the lower clamping mechanism 2, and the rear end is connected to a vacuum pump through an air pipe for absorbing the non-stick surface of the ...

Embodiment 2

[0042] A winding method, realized according to the tape winding machine described in embodiment 1, comprises the following steps:

[0043] Step 1: Place the front end of the adhesive tape on the upper clamping mechanism 1 and perform clamping.

[0044] Step 2: The lower clamping mechanism 2 uses the fourth cylinder 15 to slide up first to clamp the lower end of the tape, and then slide down to pull out the tape. During the process of pulling the tape, the upper clamping mechanism 1 releases the tape.

[0045] Step 3: After the lower clamping mechanism 2 has finished pulling the tape, use the first cylinder 8 to push the negative pressure plate 3 to the vicinity of the tape or stick it to the tape, and the vacuum pump is turned on, and the negative pressure plate 3 Negative pressure is generated to attract the non-stick side of the tape.

[0046] Step 4: The claws of the lower clamping mechanism 2 are opened, the tape is released, and then rotated at a certain angle (20°-60°) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com