Tabletting device for medicine production

A tableting device and a technology for producing medicines, which are applied to presses, material forming presses, manufacturing tools, etc., can solve the problems of affecting the quality of medicines, easy adhesion of medicines, incomplete medicines for tableting, etc., and achieve a good linkage effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

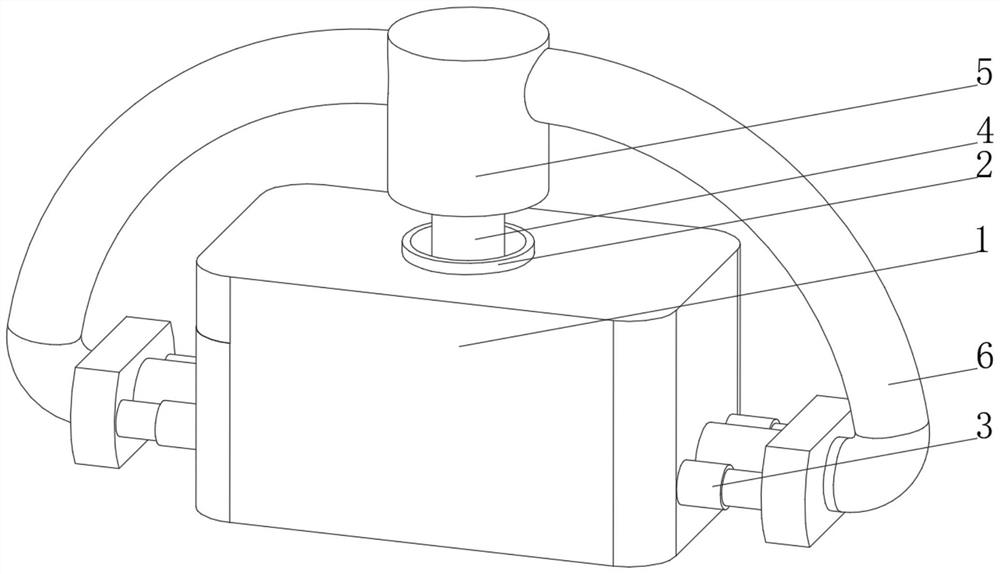

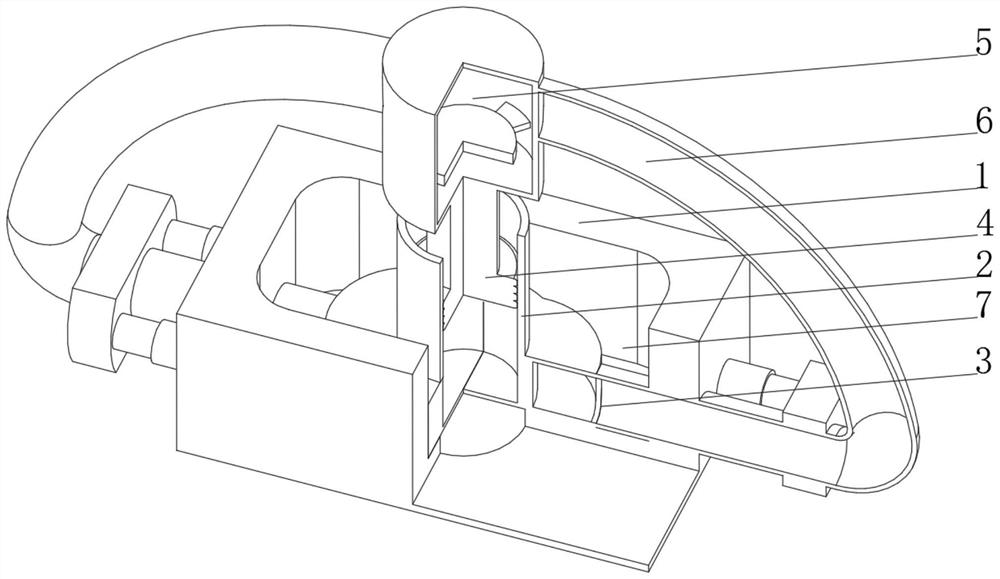

[0033] see Figure 1-3 , the present invention provides a technical solution: a drug production tablet pressing device, specifically comprising:

[0034] The fixed seat 1 is provided with a material storage tube 2 inside the fixed seat 1, and the bottom of the material storage tube 2 is connected with a forming device 3. The forming device 3 is provided with two groups and symmetrically distributed on both sides of the bottom of the material storage tube 2. A movable cavity 7 matching the molding device 3 is provided, and the molding device 3 can slide inside the movable cavity 7;

[0035] Piston 4, the top of the piston 4 is fixedly connected with a control device 5, and both sides of the control device 5 communicate with the molding device 3 through a hose 6;

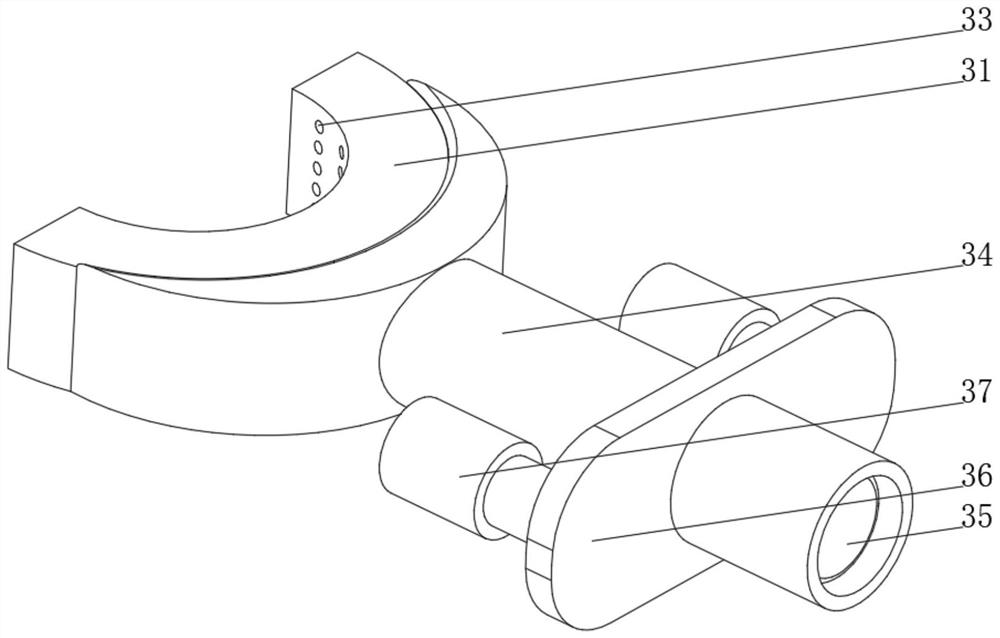

[0036] Forming device 3 comprises:

[0037] Forming base 31, the inner wall of the forming base 31 is provided with a semi-arc shape, the inside of the forming base 31 is provided with a liquid storage chamber 32, a...

Embodiment 2

[0043] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the control device 5 includes a sliding sleeve 51, the inner wall of the sliding sleeve 51 is slidably connected with a control rod 52, and the inner wall of the sliding sleeve 51 is fixedly connected with a support through a pole 56 Platform 53, the side of support platform 53 close to control lever 52 is connected with control lever 52 by control spring, both sides of control lever 52 are fixedly connected with arc-shaped connecting rod 54, and the part of sliding sleeve 51 inner wall positioned at support platform 53 slides A control piston 55 is connected, the top of the sliding sleeve 51 is connected to the stamping device, the bottom of the sliding sleeve 51 is slidingly connected to the piston 4 through a limiter, the control rod 52 is fixedly connected to the piston rod of the piston 4, and the inner wall of the sliding sleeve 51 is set There is a chute 57 adapted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com