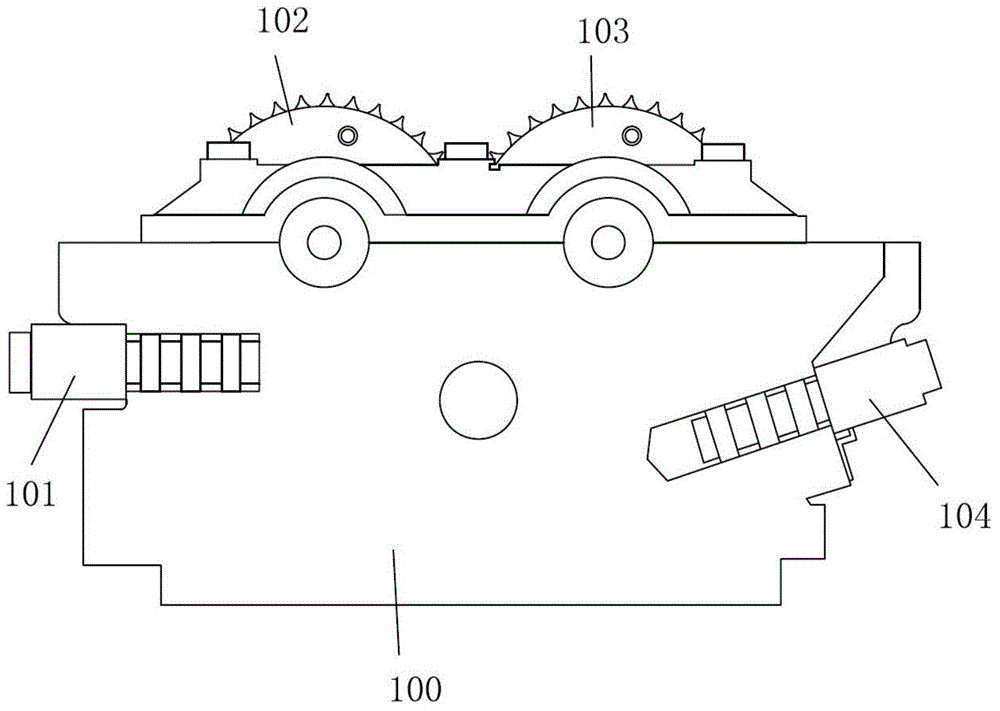

Oil duct structure of VVT (variable valve timing) system

An oil channel and pressure cavity technology, applied in the field of oil channel structure, can solve the problems of failure of oil channel switching mechanism, complicated operation of OCV valve, general circulation effect, etc., to achieve the effects of simple assembly, improved service life, and avoidance of direct impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

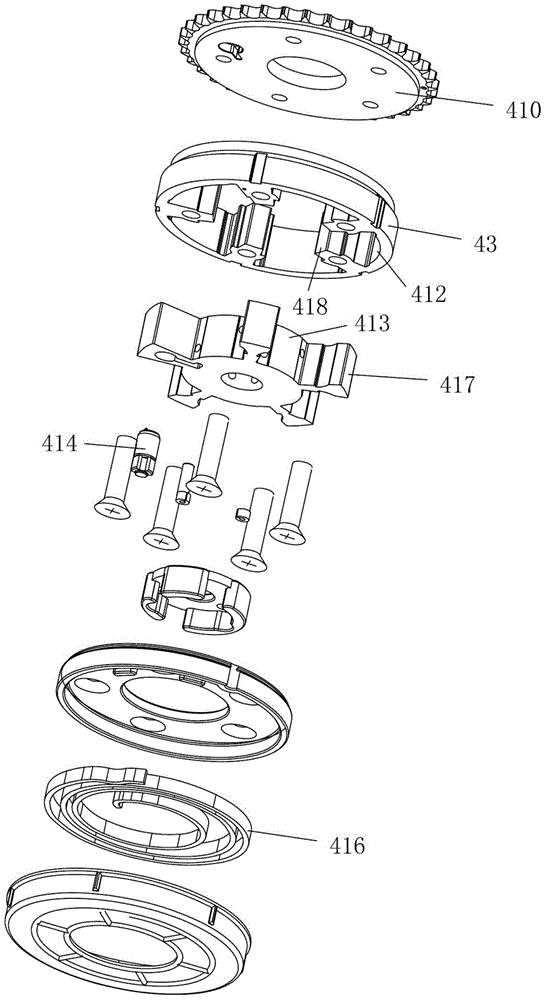

[0051] Embodiment 1: An oil passage structure of a VVT system, including a camshaft phaser and an OCV valve. The camshaft phaser includes a rotor 44 and a stator 43. The stator 43 is provided with several pressure-holding chambers, and the base of the rotor 44 The outer side is provided with evenly distributed blades 42, the blades 42 extend into the pressure holding chamber and divide the pressure holding chamber into an advanced angle pressure holding chamber and a late angle pressure holding chamber 41, the rotor base and the blades are integrated structure, the rotor The outer peripheral surface 413 of the base and the inner peripheral surface 418 of the stator are bonded without damping and are fluid-tight, and the outer peripheral surface 417 of the blade is bonded to the inner peripheral surface 412 of the pressure-holding chamber without damping and are fluid-tight. The integral structure of the rotor base and the blades of the present invention can effectively improve ...

Embodiment 2

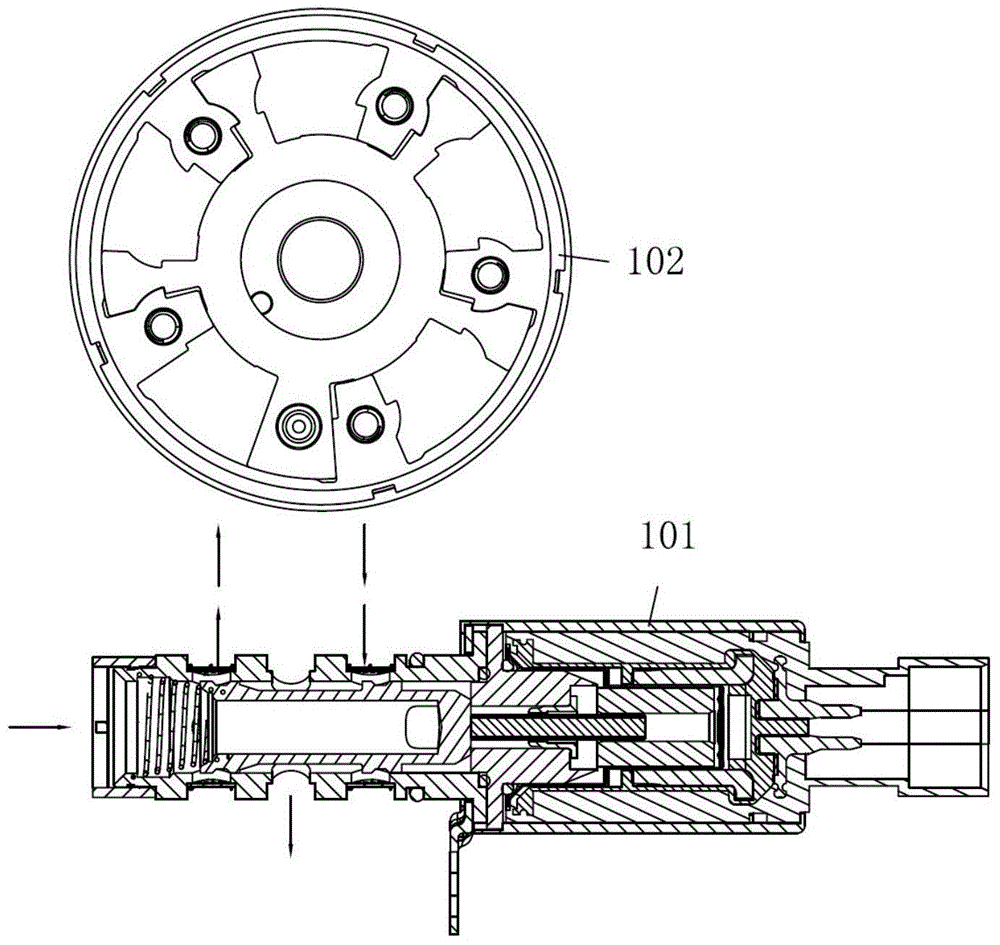

[0065] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that the ejector rod 33 and the reversing rod 34 of the OCV valve are of an integrated structure, and the front end of the ejector rod 33 is against the valve core 31 Central; the lower end of the skeleton is connected with a base, and the side of the base facing the valve core is provided with a magnetic isolation sheet 32; The through hole and the magnetic isolation sheet 32. The design of the magnetic isolation sheet 32 makes the solenoid valve assembly more efficient and more practical. This embodiment not only solves the matching problem caused by looseness between the ejector rod and the valve core, but also saves assembly steps and reduces costs. In addition, in this embodiment, exhaust grooves can be provided on the peripheral side of the valve core as required to ensure smooth flow of air between the chambers on the upper and lower sides of the valve core. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com