Ancient coin dust removal device

A technology for dust removal device and ancient coins, applied in the field of machinery, can solve the problems of poor cleaning effect, affect the aesthetics of ancient coins, discount on packaging quality, etc., and achieve the effects of improving dust removal effect, avoiding contact and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

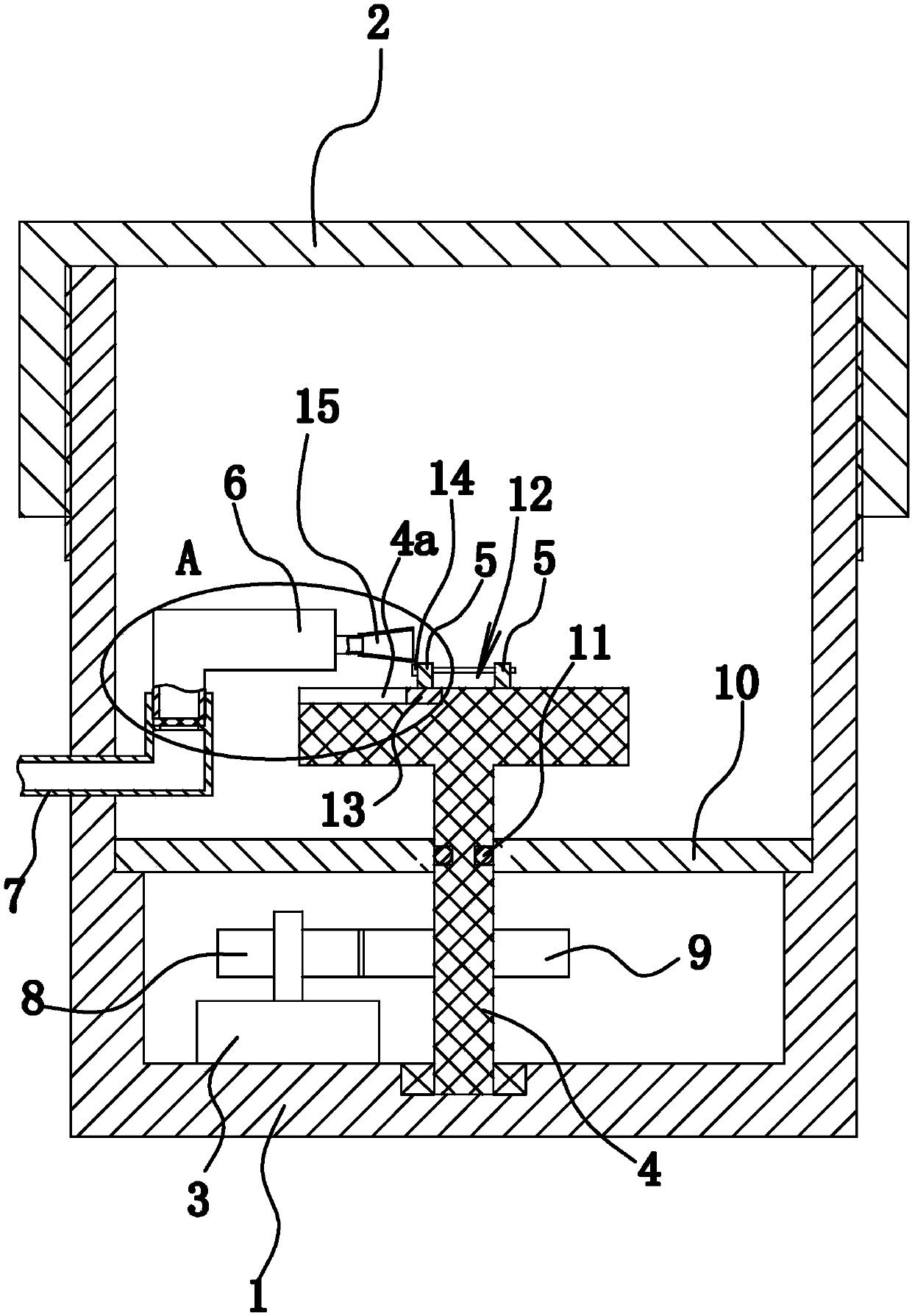

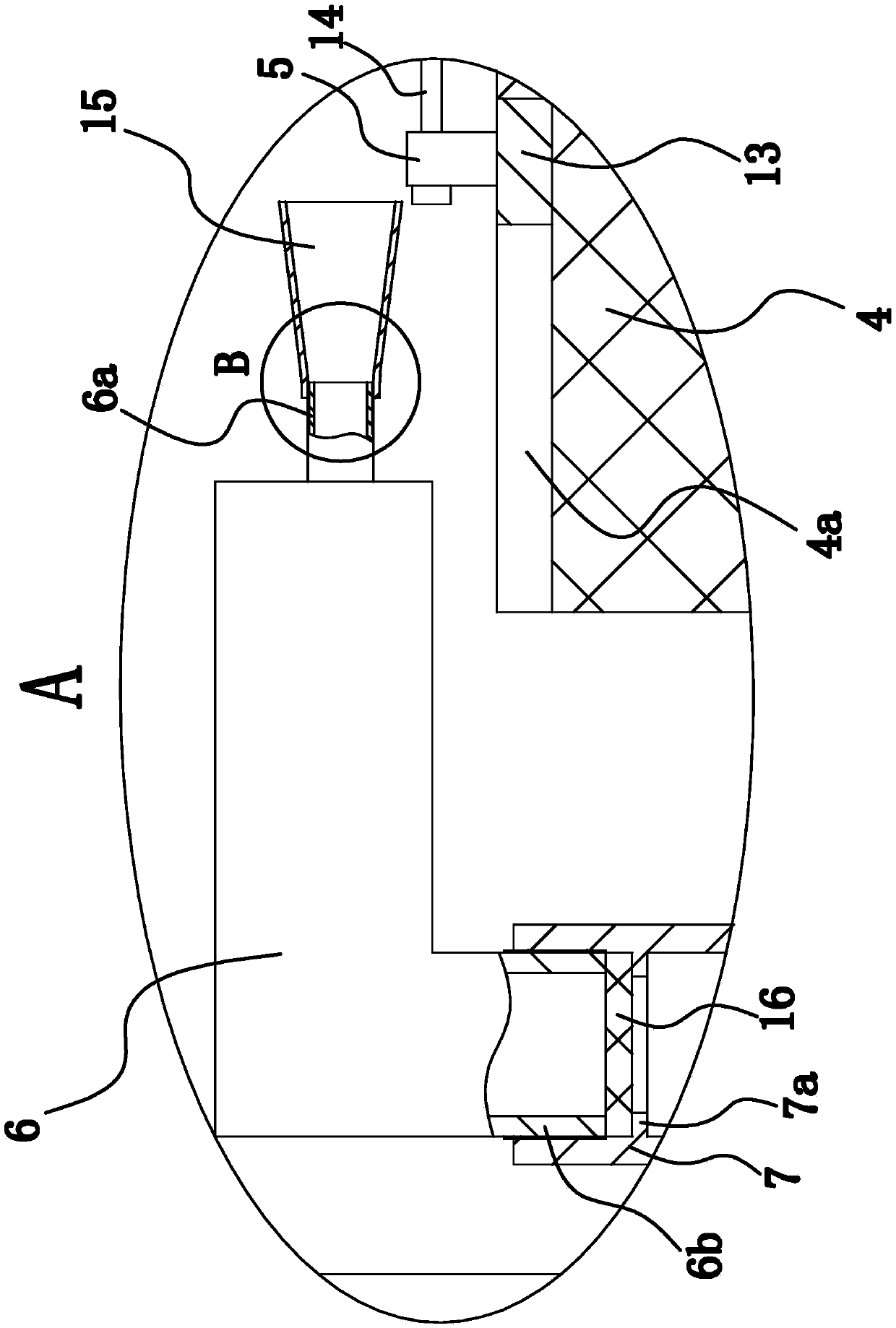

[0032] Such as figure 1 and figure 2 As shown, the ancient coin dedusting device is composed of a barrel body 1, a barrel cover 2, a frequency conversion motor 3, a rotating shaft 4, a splint 5, a spray gun 6, a nitrogen pipe 7, and the like. Among them, the preferred spray gun 6 is an automatic spray gun.

[0033] Specifically, the bucket body 1 is arranged vertically, the bottom wall of the bucket body 1 is closed and the top is open. The bung 2 is covered on the staving 1 to seal the bung of the staving 1 . Preferably, the barrel cover 2 is connected with the barrel body 1 through a threaded structure.

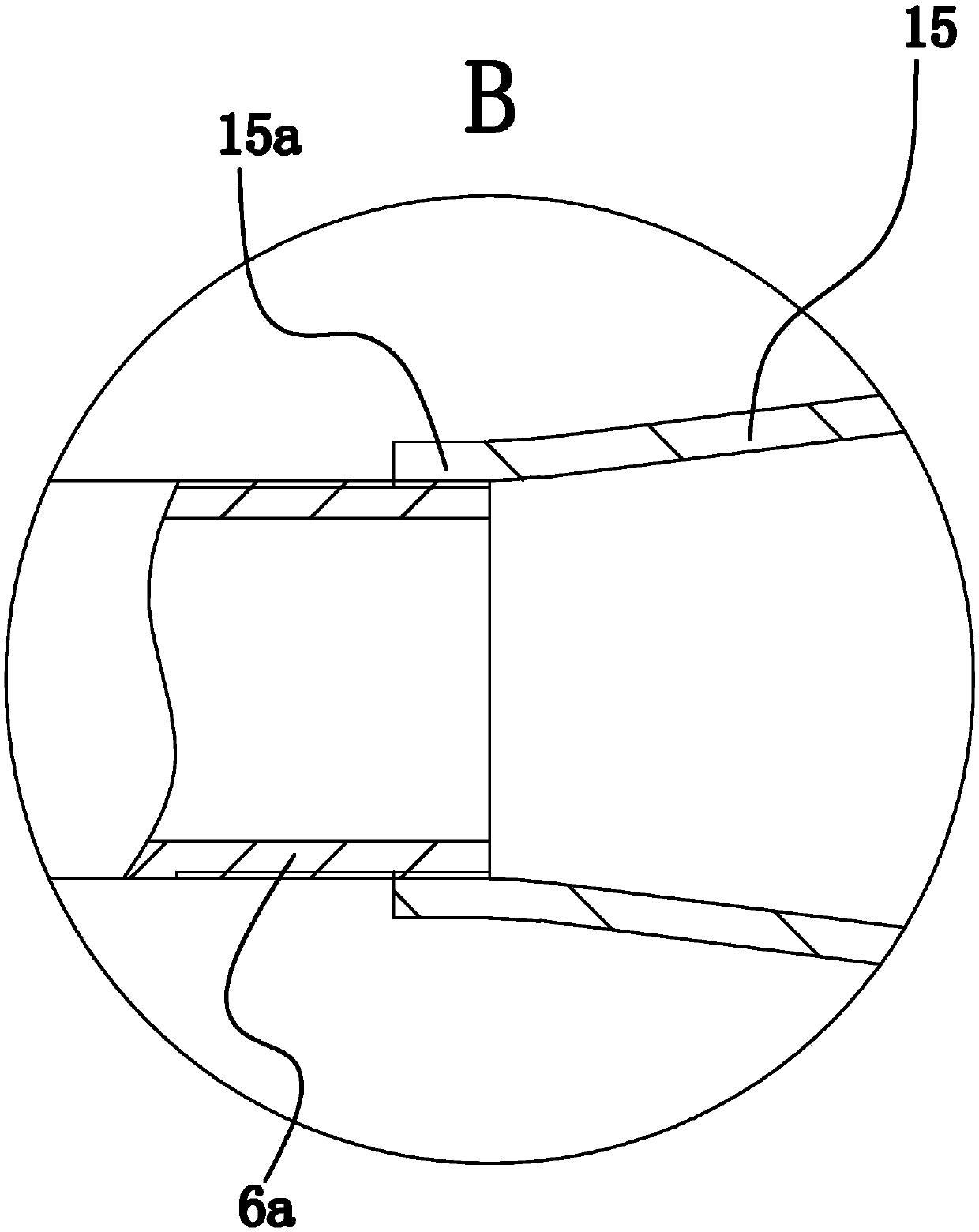

[0034] The rotating shaft 4 is vertically arranged in the staving body 1, the diameter of the upper end of the rotating shaft 4 is greater than the diameter of the lower end of the rotating shaft 4, and the lower end of the rotating shaft 4 is axially fixed to the staving body 1. In this embodiment, the lower end of the rotating shaft 4 is axially fixed to the barrel b...

Embodiment 2

[0043] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the transmission mechanism includes a driving wheel fixedly connected to the output shaft of the variable frequency motor 3 and a driven wheel fixedly connected to the rotating shaft 4, and the driving wheel It is connected with the driven wheel through a synchronous belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com