Aluminum profile manufacturing process

A manufacturing process and aluminum profile technology, which is applied in the field of aluminum profile preparation and can solve problems such as slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

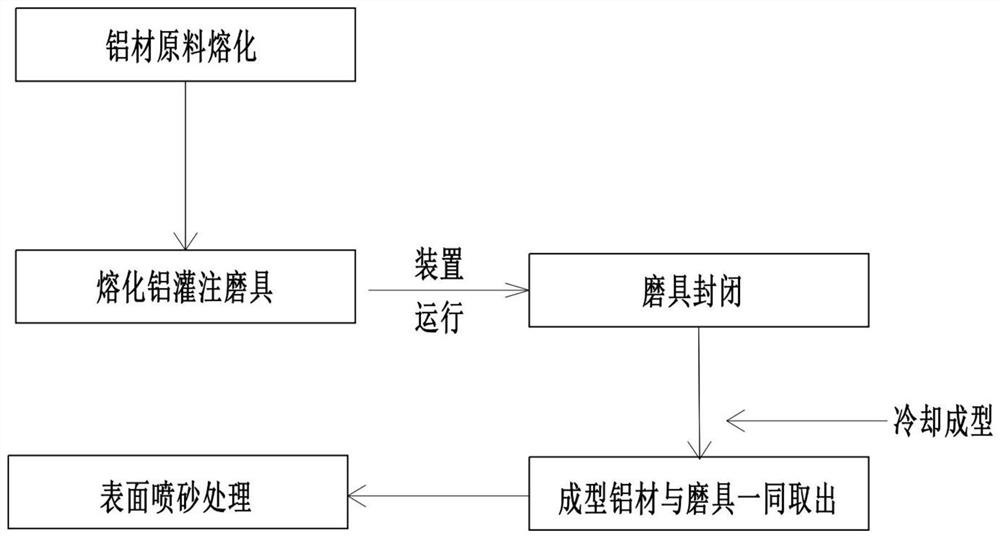

[0024] An aluminum profile manufacturing process, the process includes the following steps: Step 1: hot-melt the recovered aluminum; Step 2: Fill the melted aluminum into the abrasive tool; Step 3: After pouring the aluminum liquid The tool is closed and cooled and formed; Step 4: Take out the formed aluminum material and the abrasive tool together, and perform sandblasting on the surface of the formed aluminum material. In traditional aluminum material processing, due to the large amount of processing, it often occurs The accumulation of formed aluminum materials, and the surface treatment of the accumulated aluminum materials will be more time-consuming and labor-intensive. The formed aluminum materials prepared through this process step can be completed after cooling and forming during the removal process. Sandblasting saves operation steps.

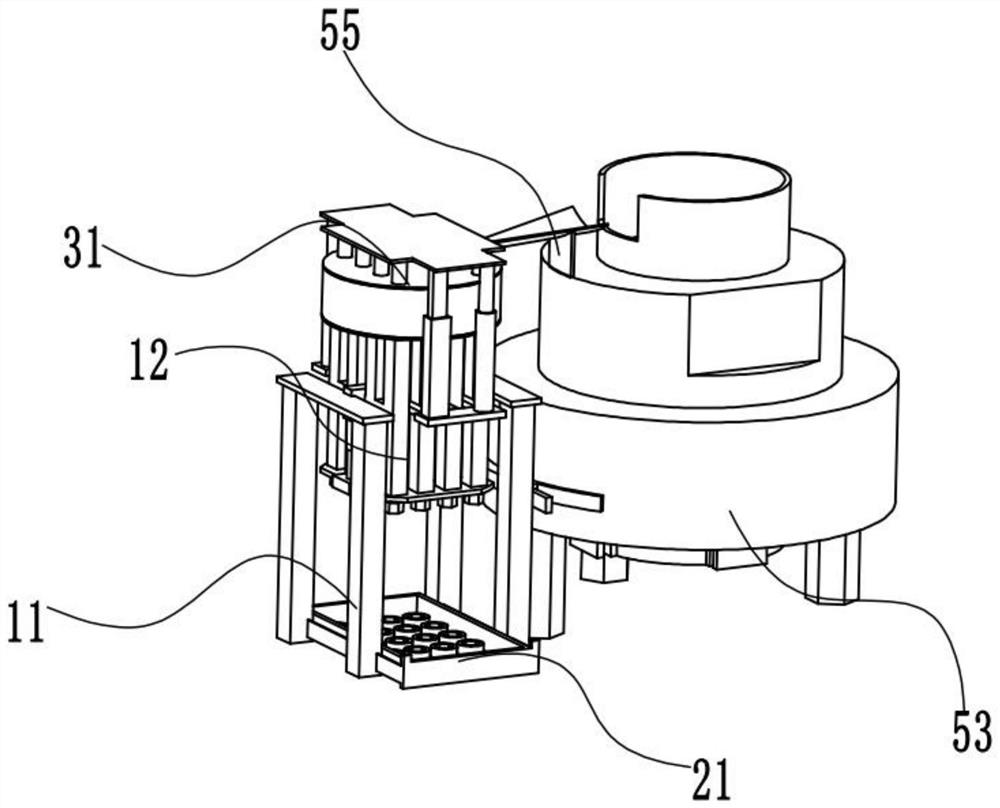

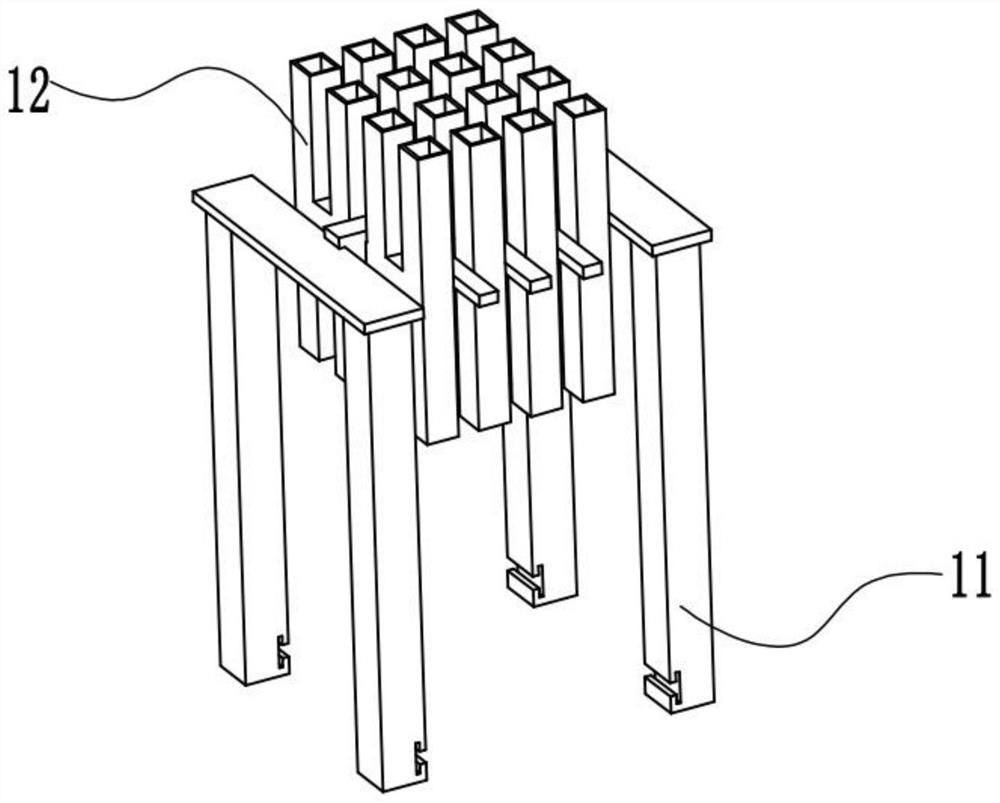

[0025] see figure 2 and image 3 , an exemplary working process of the support part that can be infused with aluminum as shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com