Top plate U rib connecting structure and construction method thereof

A technology for connecting structures and construction methods, applied to bridge parts, erecting/assembling bridges, bridge materials, etc., can solve problems such as fatigue damage at the joint of U-ribs, weakening of U-rib stiffness, etc. Effect of reducing stiffness and avoiding fatigue problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

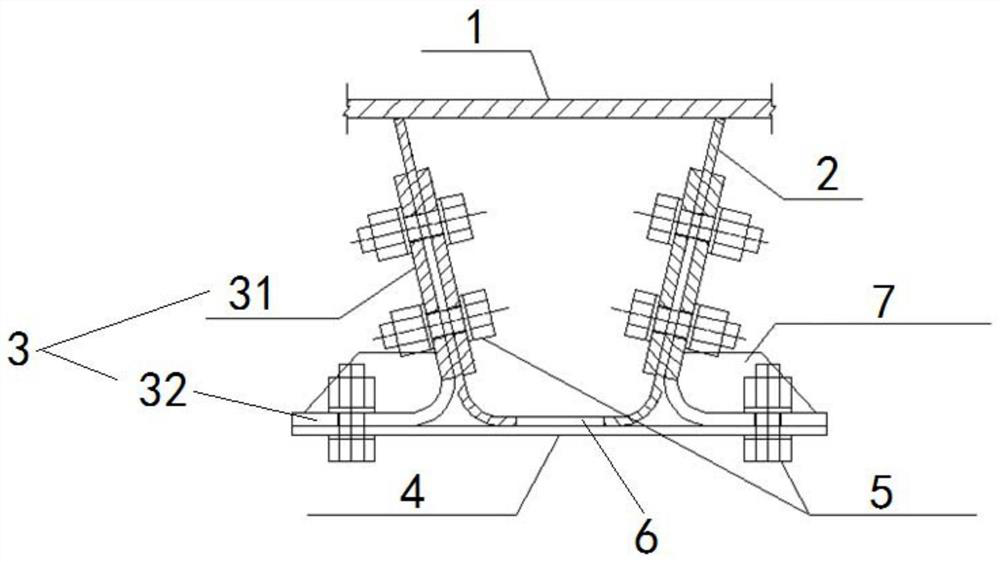

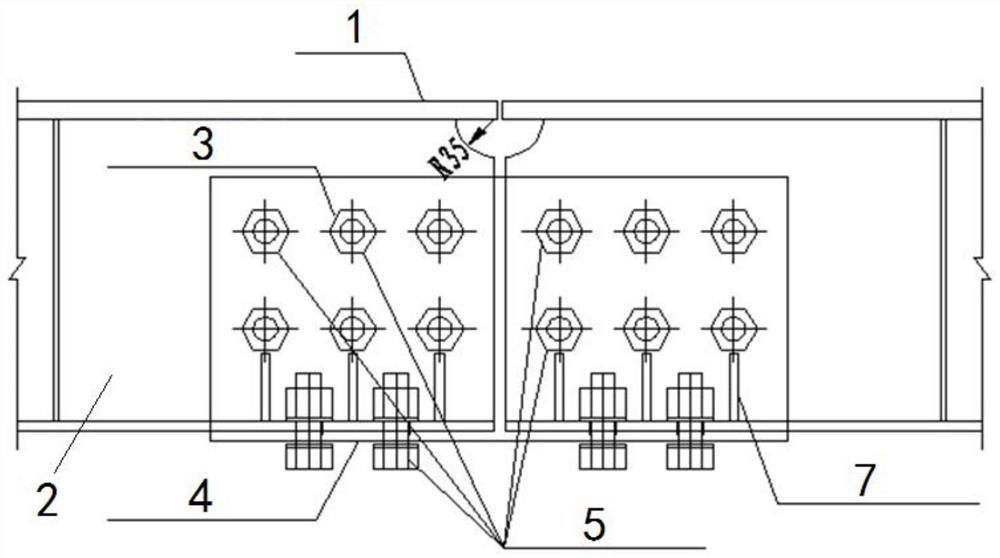

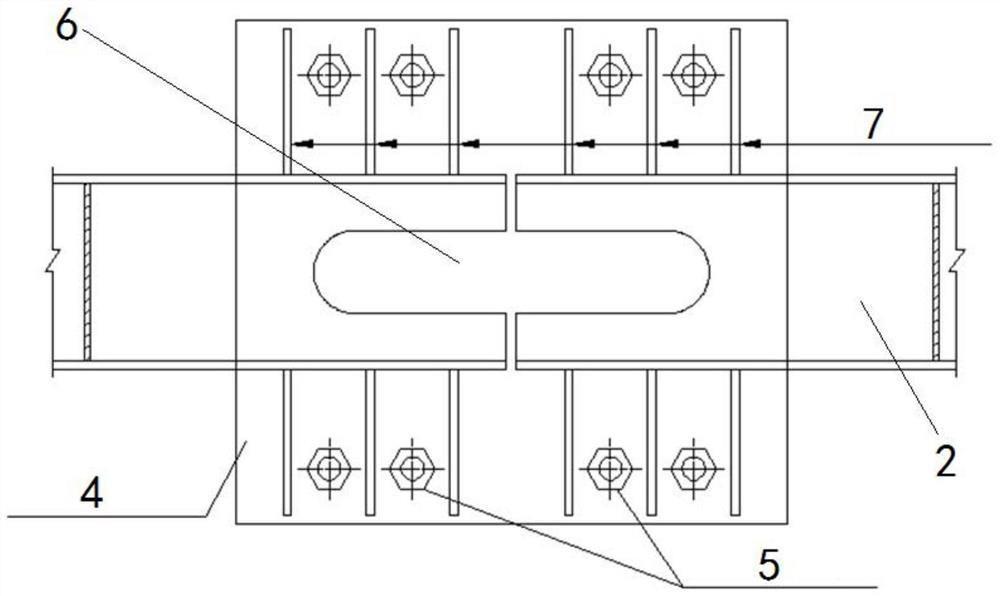

[0037] A roof U-rib connection structure, such as Figure 1~3 As shown, it includes top plate 1, U rib 2, web connecting plate 3, bottom plate connecting plate 4, high-strength bolts 5 and hand holes 6. The U rib 2 is welded on the lower surface of the top plate 1, and the web connecting plate 3 and the bottom plate connecting plate 4 are detachably arranged at the joint of the U rib 2 through high-strength bolts 5 . Wherein, the web connecting plate 3 is arranged on the outer side of the U rib 2, and the structure is as follows Figure 4 As shown, it includes a U rib connecting portion 31 and a bottom plate connecting portion 32 arranged at an angle. Bolt holes 33 are provided, and the bottom surface of U rib 2 is provided with hand holes 6, such as figure 1 As shown, the U-rib connecting portion 31 is fixed on the side wall of the U-rib 2 by high-strength bolts 5, and the bottom-plate connecting portion 32 is fixed on the bottom-plate connecting plate 4 by high-strength bo...

Embodiment 2

[0039] A U-rib connection structure of the top plate, stiffening ribs 7 are arranged on the bottom plate connection part 32 to strengthen the structural strength, and the rest of the structure is the same as that of Embodiment 1.

[0040] The preparation and construction methods of the roof U-rib connection structure of this embodiment are as follows:

[0041] The first step: cutting and processing the web connecting plate 3 in the factory, transforming the original rectangular connecting plate into an L-shaped connecting plate, and setting stiffeners 7 to weld it for reinforcement;

[0042] Step 2: Pre-assemble the sections in the factory, locate the high-strength bolt holes on the U rib 2, the web connecting plate 3, and the bottom plate connecting plate 4, and precisely make the holes at the bottom of the U rib 2 at the end of the segment on both sides A hand hole 6 is provided to facilitate the tightening of high-strength bolts 5;

[0043] Step 3: At the splicing site, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com