A kind of installation equipment and using method thereof for large ceiling decoration project

A technology for installing equipment and ceilings, applied in metal processing equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of consuming the physical strength of the staff, heavy burden on the staff, inconvenient decoration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

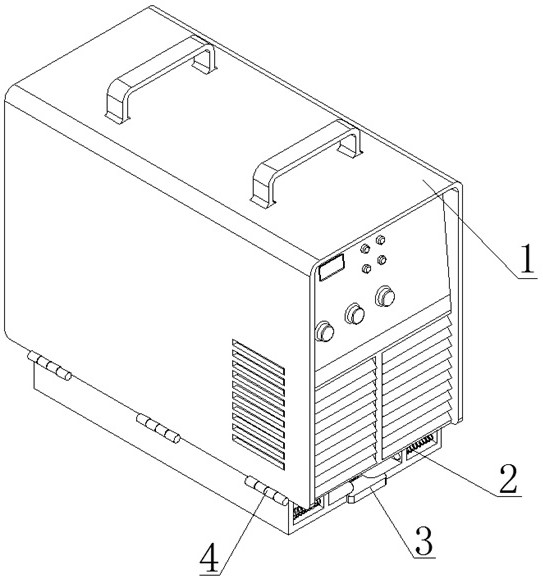

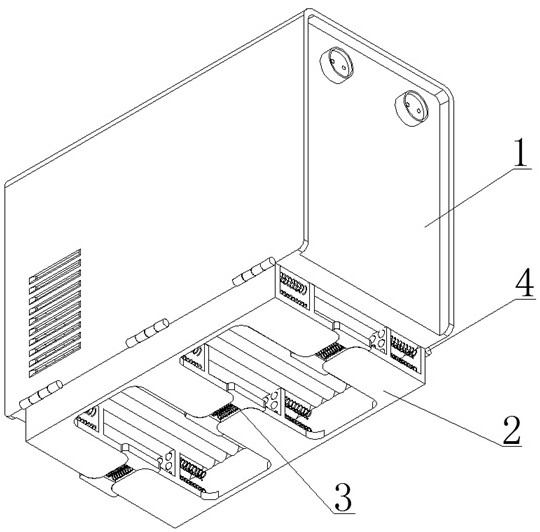

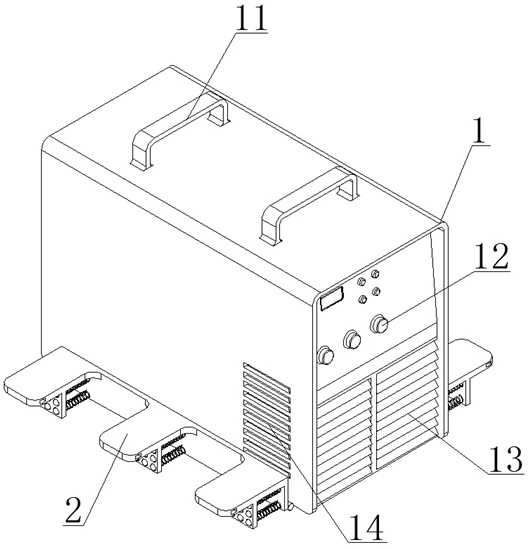

[0020] Example: refer to figure 1 and figure 2 Shown: an installation device for large ceiling decoration engineering, including welding machine 1, clamping plate 2, limit head 3 and hinge 4; the bottom of both sides of welding machine 1 is connected with clamping plate 2 through hinge 4, and two The clamping plates 2 are connected through the limit head 3; the welding machine 1 is convenient to install the decorations on the ceiling steel frame by welding when installing the decorations, and the clamping plate 2 is convenient for the welding machine 1 to be stuck on the steel frame, and then It is convenient for the welding machine 1 to be stably placed on the steel frame, thereby facilitating the use and installation of the welding machine 1, and the limit head 3 is convenient for connecting two clamping plates 2 when using the clamping plates 2, thereby facilitating the connection and deployment of the clamping plates 2 , the hinge 4 is convenient to connect the clamp 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com