Gas supply process for marine fuel tank

A marine fuel and process technology, applied in the field of marine fuel tank gas supply process, can solve problems such as tension, and achieve the effect of ensuring energy saving, low energy, and high commercial development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

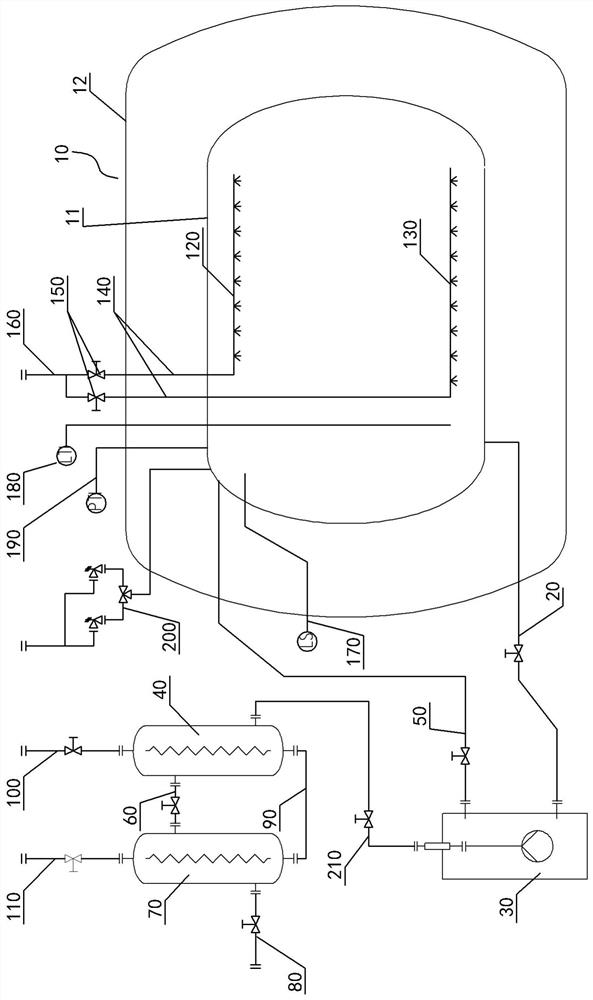

[0017] A gas supply process for marine fuel tanks, see figure 1 , which includes a double-layer tank body 10, the double-layer tank body is specifically an inner tank 11 and an outer tank 12, and LNG is stored in the inner tank 11, and the bottom fuel outlet of the inner tank 11 is connected to the double-layer tank through a first pipeline 20 The inlet of the submersible pump 30 outside the body 10, the liquid outlet of the submersible pump 30 is connected to the medium inlet of the LNG vaporizer 40 through the eighth pipeline 210, and the gas outlet of the submersible pump 30 is returned to the inside through the second pipeline 50. The top return port of the tank 11, the medium outlet of the LNG gasifier 40 is connected to the medium inlet of the heater 70 through the third pipeline 60, the medium outlet of the heater 70 outputs gas fuel through the fourth pipeline 80, and the heating medium passes through the first Seven pipelines 110 feed the heating medium into the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com