Cable tunnel cable heating monitoring and fire suppression system

A cable tunnel and fire technology, applied in the field of electric power, can solve problems such as increased leakage current, difficult to find and deal with, insulation aging, etc., and achieve the effect of preventing the deterioration of the fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

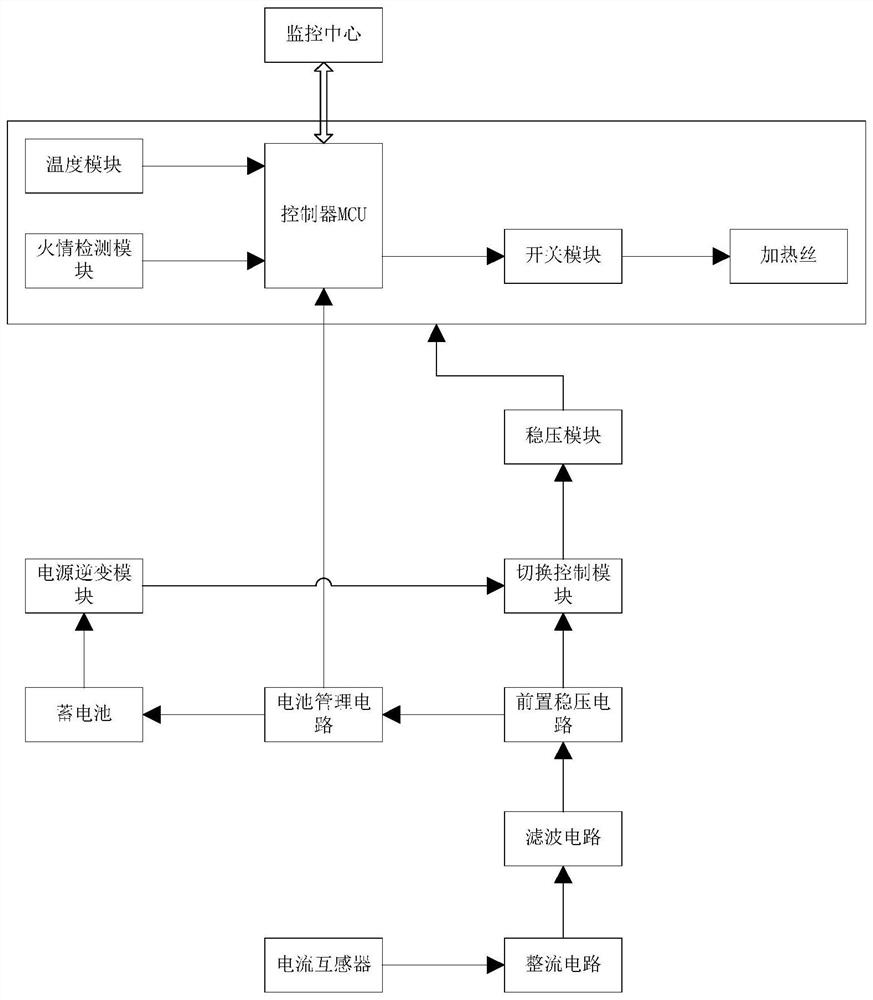

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

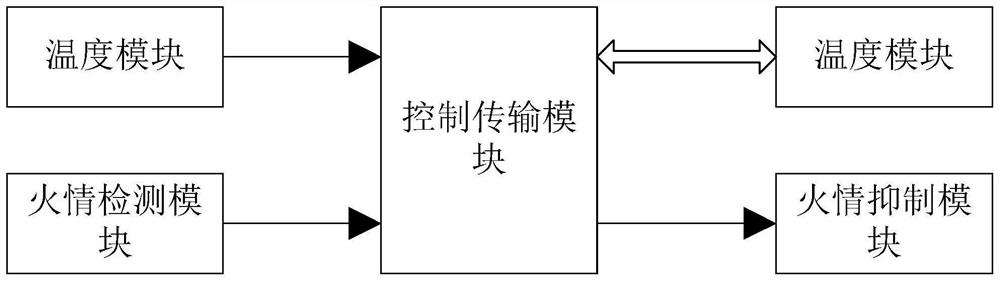

[0029] A cable tunnel cable heating monitoring and fire suppression system provided by the present invention includes a temperature detection module, a fire detection module, a control transmission module and a fire suppression module;

[0030] The temperature module is arranged at the cable joint, and is used to detect the temperature signal at the cable joint and transmit it to the control transmission module;

[0031] The fire detection module is used to detect fire parameters in the cable tunnel and transmit them to the suppression transmission module;

[0032] The suppression transmission module is used to receive the parameter information output by the temperature module and the fire detection module, and judge whether a fire occurs, upload the parameter information to the monitoring center and output a trigger control signal to the fire suppression module when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com