Flying platform with large-span S-bend air intake and exhaust system

An exhaust system, intake and exhaust technology, applied in the field of flying platform, to achieve the effect of effective and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

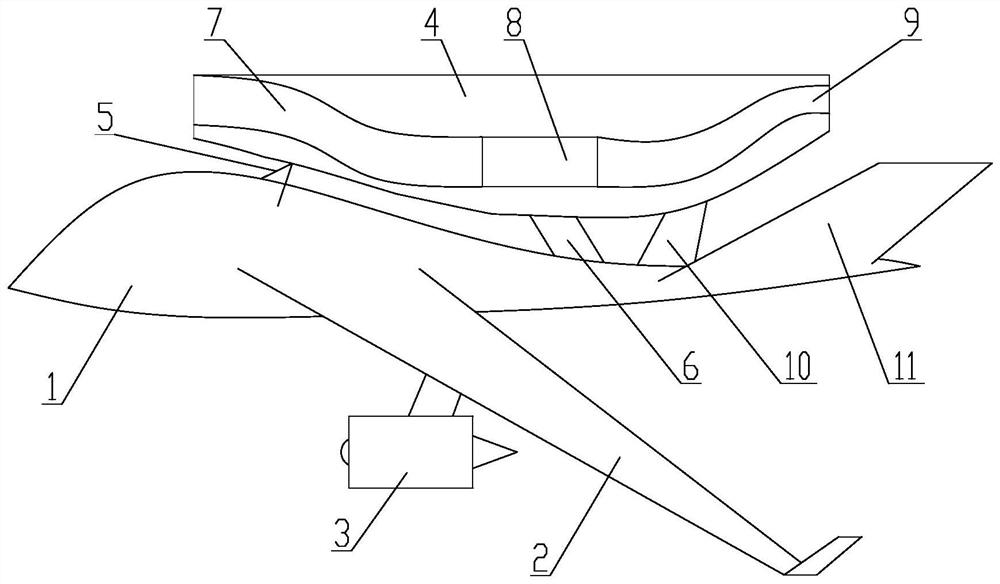

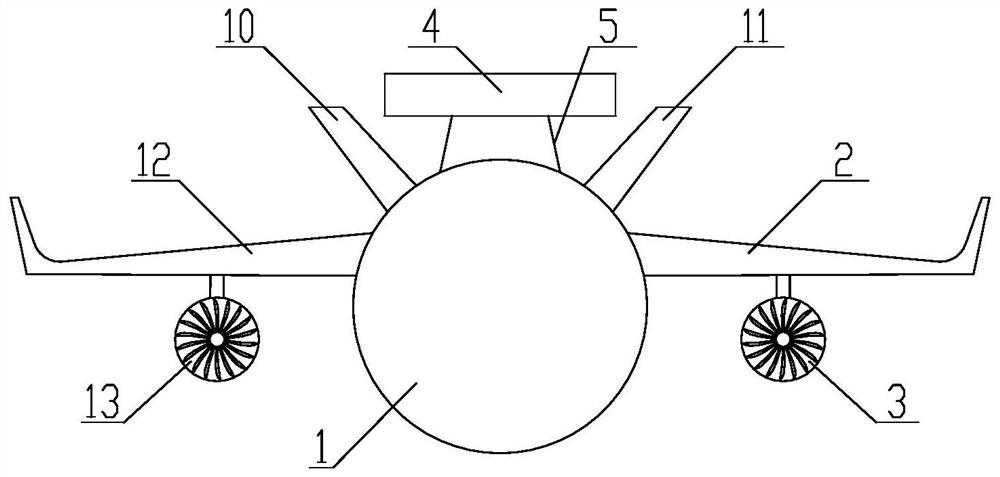

[0018] A flying platform with a large-span S-curve intake and exhaust system includes an aircraft body 1, wings, an original aeroengine, a test chamber 4 and an aeroengine 8 for testing. The aircraft body 1 is the main body of the aircraft, and the wings include a main wing and an empennage, and the original aero-engine is arranged on the main wing. Because the test aero-engine 8 requires a special large-span S-curved air intake and exhaust system operating environment, the test cabin 4 is arranged above the aero-engine, and a support structure is provided between the test cabin 4 and the aircraft body 1. The aero-engine 8 for the test is arranged in the middle part of the test cabin 4, and the aero-engine 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com