Metallographic structure display method for hafnium metal, hafnium metal and plasma torch cathode core

A technology of metallographic structure display and metallographic structure, applied in the field of ion torch cathode core, can solve the problem of difficult to clearly display the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the present invention provides a method for preparing hafnium metal, comprising the following steps:

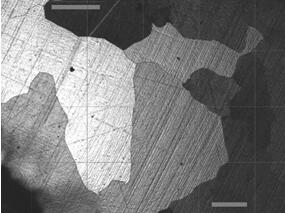

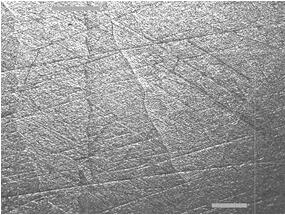

[0037] Step S1', performing step-by-step grinding and polishing on the hafnium metallographic sample;

[0038] Step S2', placing the polished hafnium metal metallographic sample in a metallographic etching solution for etching;

[0039] Step S3', taking out the metallographic sample of the hafnium metal, cleaning and drying it, and observing the microstructure of the metallographic sample of the hafnium metal;

[0040] In this embodiment, step S1 ′, step S2 ′ and step S3 ′ are consistent with the corresponding steps of the method for displaying the metallographic structure of hafnium metal, and will not be repeated here.

[0041] Step S4', according to the observed grain size of the metallographic sample of the hafnium metal, adjust the subsequent vacuum heat treatment preparation process of the hafnium metal to obtain the hafnium metal with an idea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com