Sizing agent for surface processing of glass fiber filter cloth and preparation method thereof

A glass fiber and sizing technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of unreasonable components, unstable quality, low glue content, etc., to improve storage stability, reduce production costs, storage good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

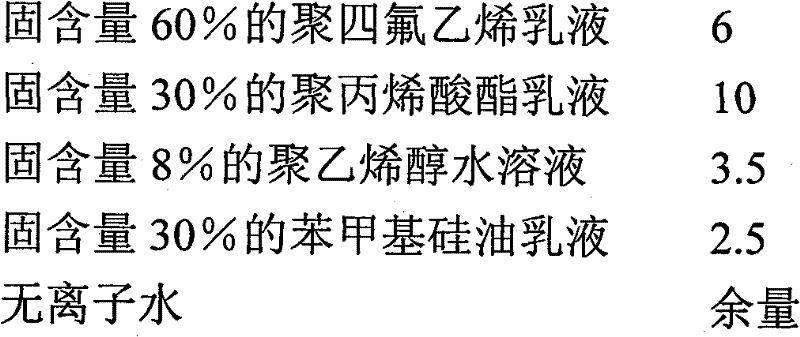

Embodiment 1

[0058] Embodiment 1 A kind of preparation method of glass fiber filter cloth aftertreatment sizing agent, comprises the steps:

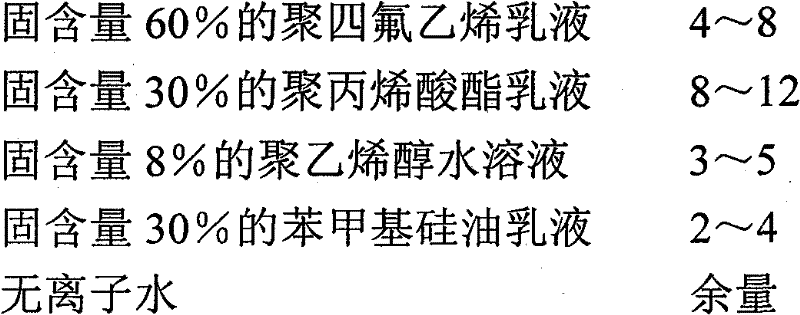

[0059] The first step. Preparation of main component A of sizing agent

[0060] 6 parts by weight of polytetrafluoroethylene emulsion with a solid content of 60% accurately metered, 10 parts by weight of polyacrylate emulsion with a solid content of 30%, 3.5 parts by weight of polyvinyl alcohol aqueous solution with a solid content of 6.5%, and benzene with a solid content of 30%. Put 2.5 parts by weight of methyl silicone oil emulsion into the wetting agent reaction kettle in sequence, add ion-free water to dilute until the total weight of the glue for wetting agent is 100 parts by weight, stir at room temperature for 20-30 minutes, and set aside;

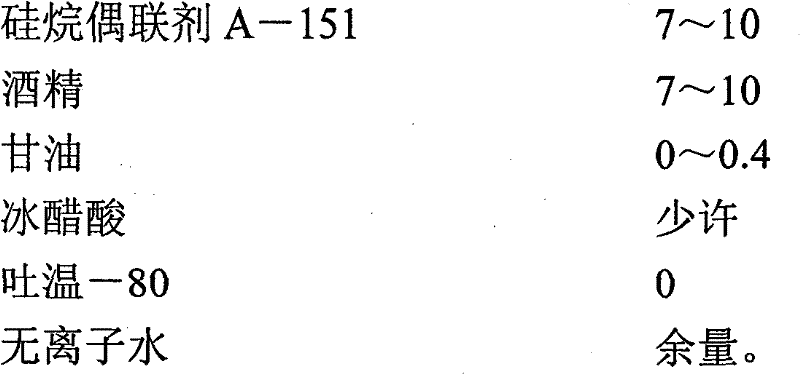

[0061] The second step. Preparation of hydrophilic coupling agent dispersion B

[0062] ①.Mix and dissolve

[0063] Accurately measure 18 parts by weight of silane coupling agent A-15, put it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com