Gearbox bearing fault detection method and system

A fault detection and gearbox technology, applied in the field of gearbox bearing fault detection methods and systems, can solve problems affecting train operation safety, maintenance lag, on-line detection of gearbox bearings, etc., to improve diagnostic accuracy and anti-interference. , improve work efficiency, increase the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

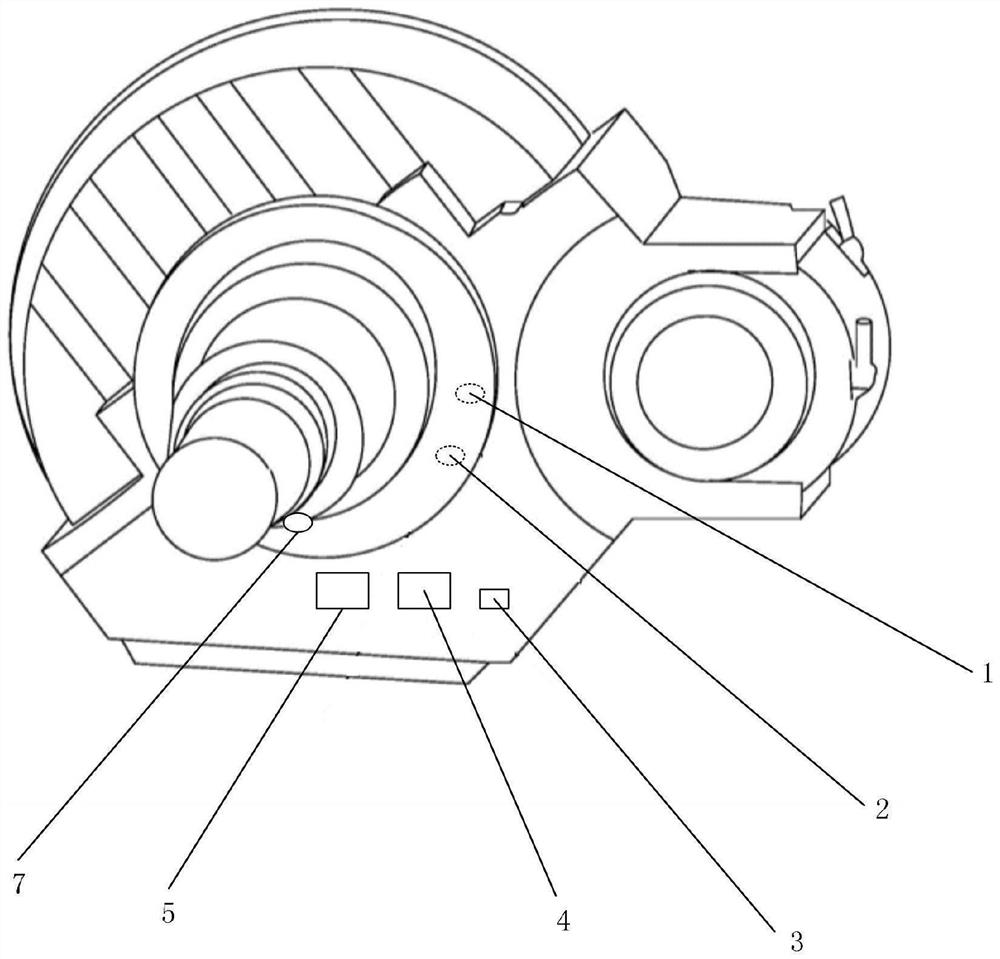

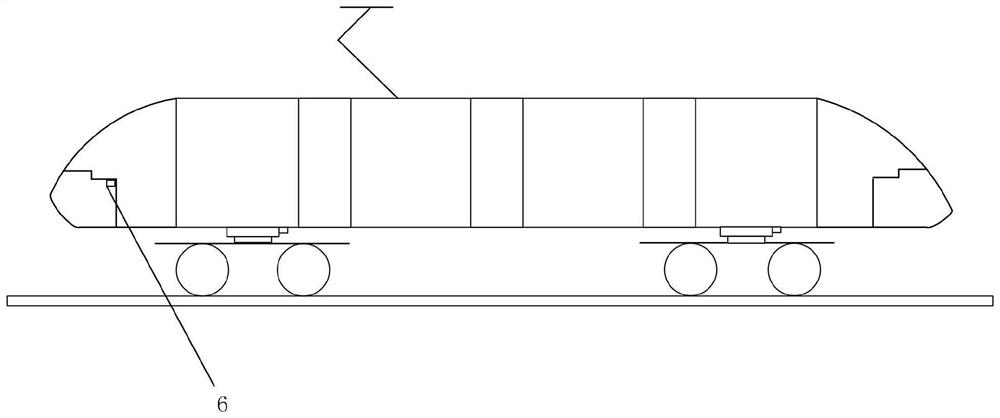

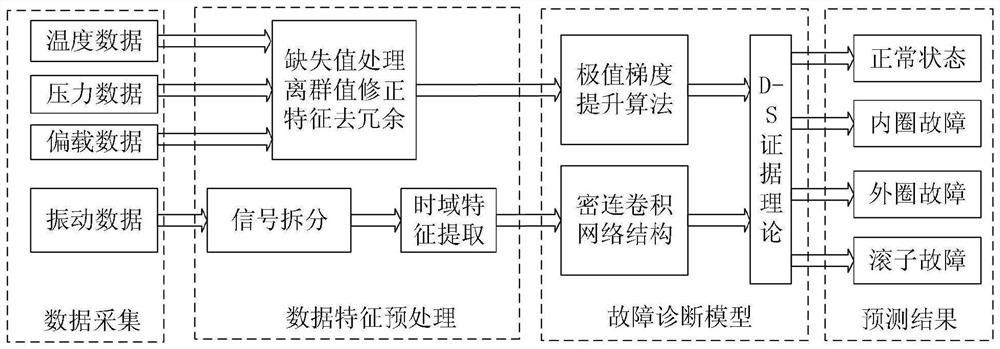

[0041] see Figure 1 to Figure 5 Shown is a gearbox bearing fault detection method and system in the present invention, including a temperature sensor 1, a vibration sensor 2, a ZigBee router 3, a control circuit board 4, a storage battery 5, a ZigBee coordinator 6, and a pressure sensor 7.

[0042] Such as figure 1 , figure 2 As shown, the temperature sensor 1 and the vibration sensor 2 are installed close to the inner wall of the bearing cover of the gearbox transmission system, the temperature sensor 1 is used to detect the temperature information of the gearbox transmission system bearings, and the vibration sensor 2 is used to detect the gearbox transmission system bearing vibration frequency, ZigBee router 3, control circuit board 4, battery 5 are installed on the surface of the gearbox, pressure sensor 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com