High-strength multi-stage aluminum alloy bridge

An aluminum alloy, multi-stage technology, applied in the direction of pipe supports, electrical components, pipes/pipe joints/fittings, etc., can solve the problems of cable fixing and cable shunting and export, and meet the requirements of safe use, use and operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

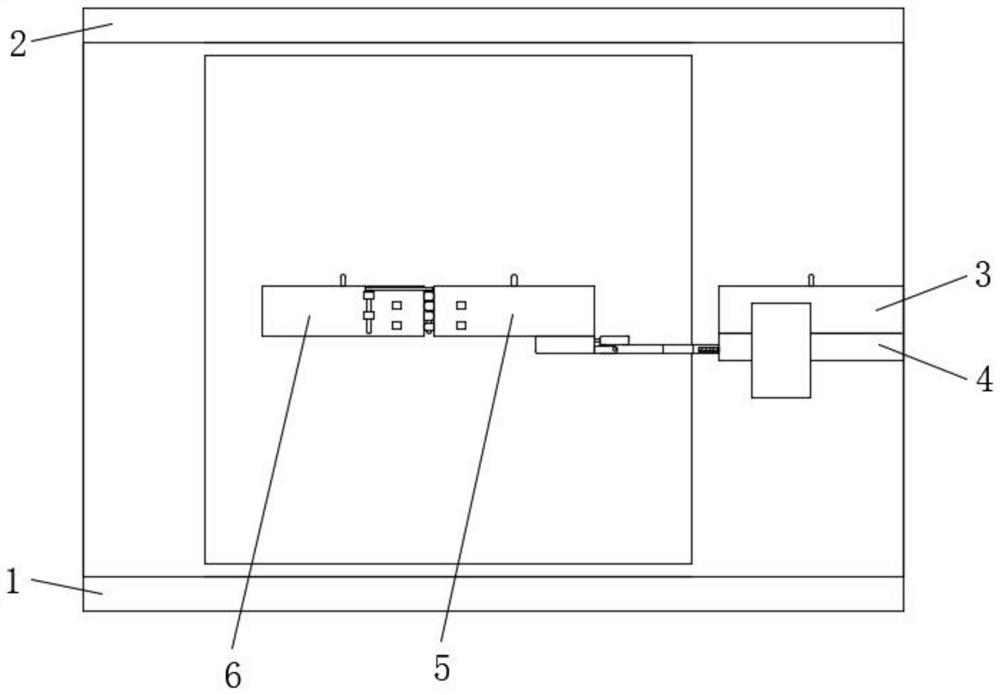

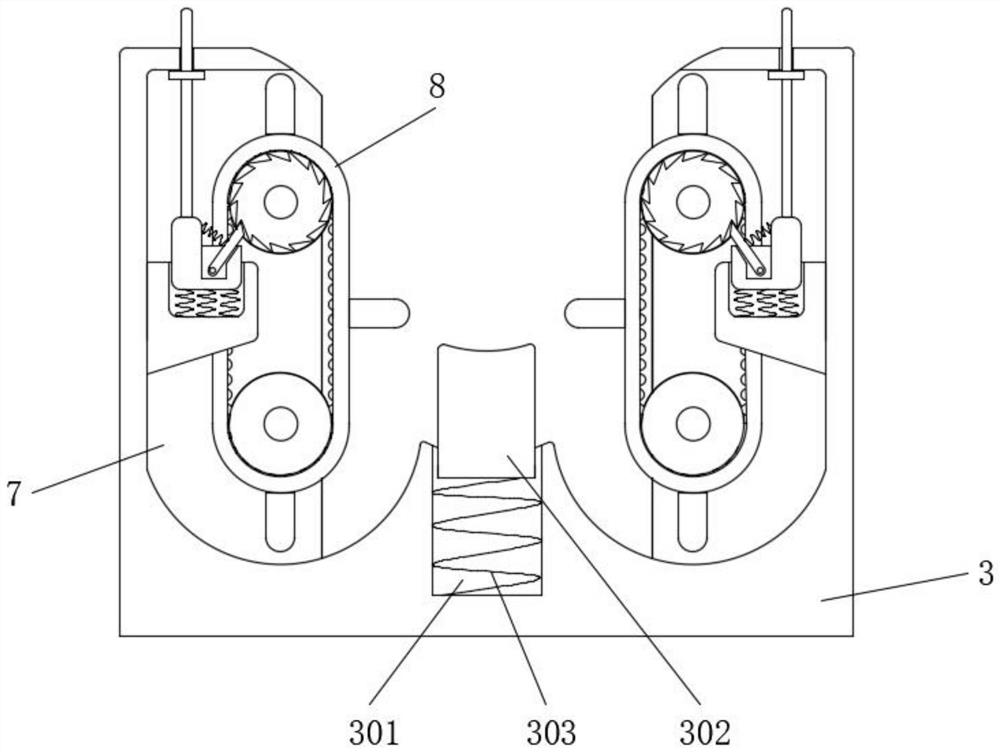

[0033] Embodiment one, by Figure 1 to Figure 3 as well as Figure 7 to Figure 9 Given, the present invention includes a bridge main body 1, the top of the bridge main body 1 is movably installed with a cover plate 2, the bridge main body 1 is a four-way structure bridge structure, and the inside of the bridge main body 1 is equidistantly fixedly installed with a first U-shaped wire-drawing groove 3 , the bottom of the first U-shaped wire holding groove 3 is equipped with a horizontal moving assembly 4, one end of the horizontal moving assembly 4 is installed with a second U-shaped wire holding groove 5, and one end of the second U-shaped wire holding groove 5 is installed with a third U-shaped wire holding groove 6, both sides of the first U-shaped wire holding groove 3, the second U-shaped wire holding groove 5 and the third U-shaped wire holding groove 6 inside are all provided with an adjustment inner cavity 7, and the inner chamber 7 is adjusted. Fixed line components 8 ...

Embodiment 2

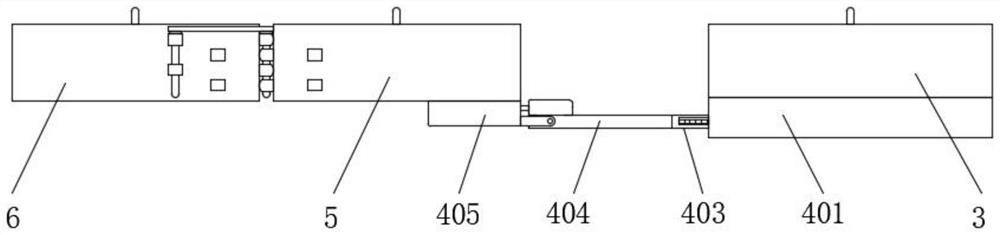

[0035] Embodiment two, on the basis of embodiment one, by figure 2 , Figure 4 to Figure 7 Given, the horizontal movement assembly 4 includes a mounting block 401, the mounting block 401 is fixedly mounted on the bottom of the first U-shaped wire slot 3, one end of the mounting block 401 is provided with a drawing slot 402, and the inside of the drawing slot 402 is movably plugged There is an L-shaped adjustment bar 403, and one end of the L-shaped adjustment bar 403 is equipped with a U-shaped block 404, and an up-and-down rotation adjustment member 405 is connected between the U-shaped block 404 and the second U-shaped line clamping groove 5;

[0036] Both sides of the draw slot 402 are symmetrically provided with a slide groove 9, and one side of the slide groove 9 is provided with a vertical card groove 10, and the inside of the vertical card groove 10 is slidably equipped with a slide block 11, and one side of the slide block 11 is connected to the slide groove. The sec...

Embodiment 3

[0041] Embodiment three, on the basis of embodiment one, by Figure 7 Given, the up and down rotation adjustment member 405 includes a lower groove block 17, the lower groove block 17 is installed at one end of the second U-shaped wire holding groove 5 bottom, and connecting pieces 18 are installed on both sides of the lower groove block 17, both sides Two connecting pieces 18 are rotationally connected with the two ends of the U-shaped block 404, and the top of the lower groove block 17 is provided with an adjustment groove 19, and the inside of the adjustment groove 19 is slidably equipped with a slide bar 20, and one side of the slide bar 20 is connected to the adjustment groove 19. A third spring 21 is installed between the ends;

[0042] A toggle block 22 is installed on the slide bar 20, a taper pin 23 is fixedly installed on one side of the slide bar 20, a riser 24 is installed symmetrically on the top of the U-shaped block 404, and a pair of first Clip 25, a pair of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com