Preparation method of crystal-broken honey

A crystallization and honey technology, applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve problems such as increased preparation costs, reduced quality of raw honey, and long consumption, and can ensure the quality of raw honey, The effect of avoiding the loss of temperature of raw honey and improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

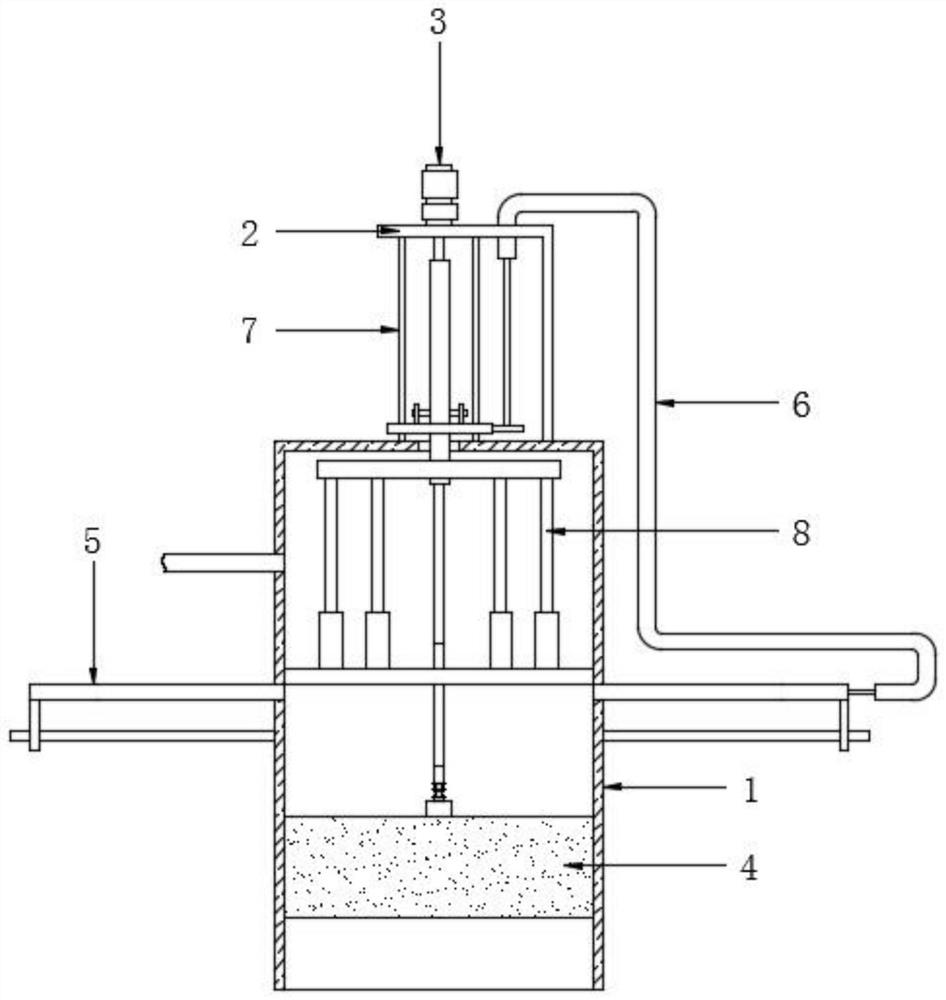

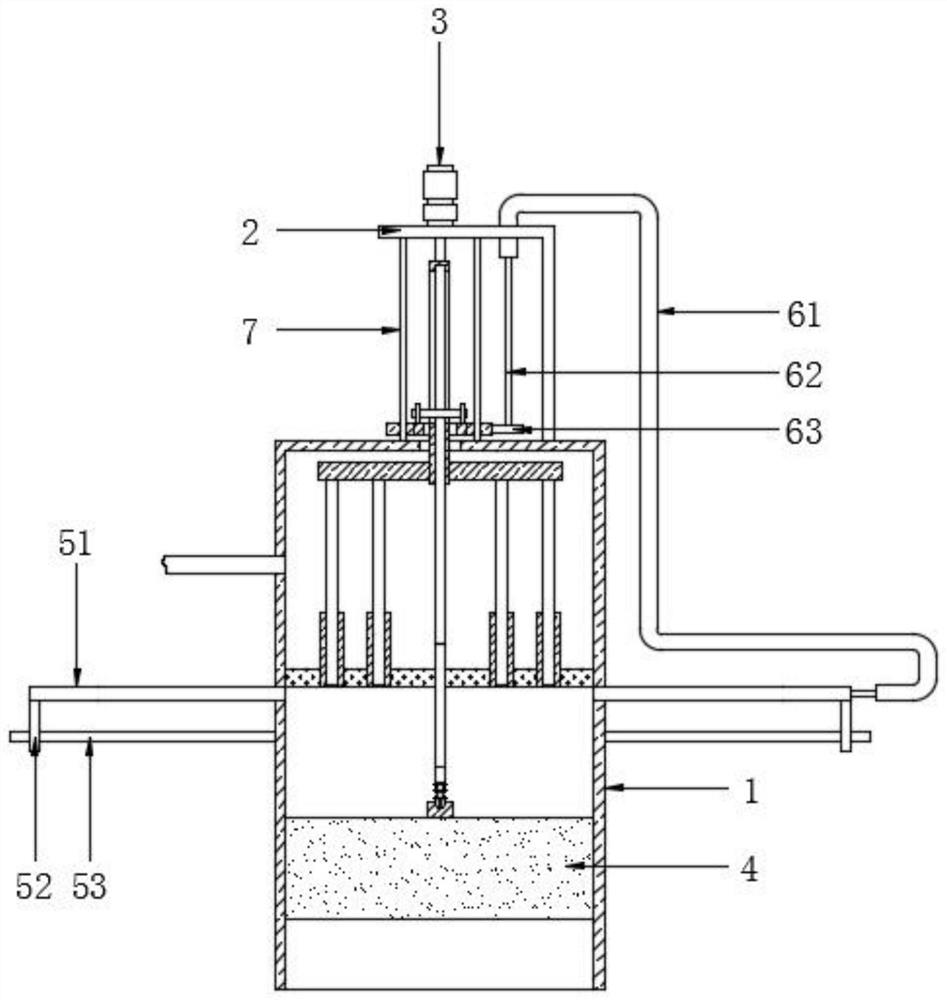

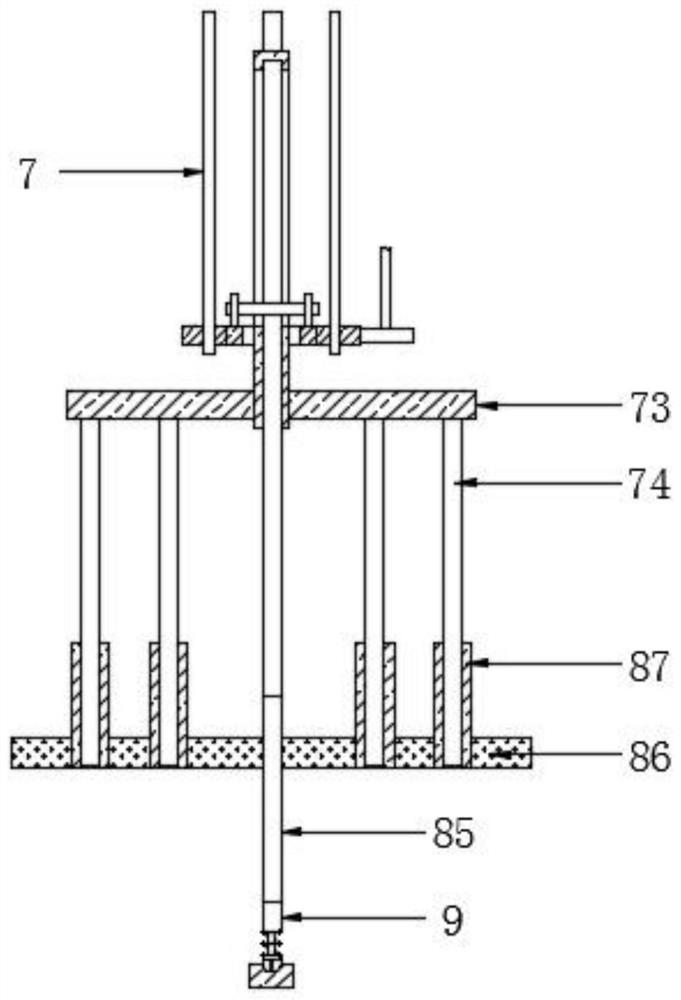

[0037] The present invention provides such Figure 1-5 A preparation method of crystal-breaking honey is shown, the preparation method is realized by using a crystal-breaking preparation device, and the crystal-breaking preparation device includes a tank body 1, and an L-shaped mounting plate 2 is fixedly arranged on the top of the tank body 1. The top of the L-shaped mounting plate 2 is fixedly provided with a drive motor 3, the bottom of the inner cavity of the tank 1 is fixedly provided with a filter assembly 4, and both sides of the tank 1 are jointly provided with a closed feeding mechanism 5, and the closed feeding The biaxial motor in the mechanism 5 drives the two sliding sealing plates 51 respectively, so that the two sliding sealing plates 51 can close or open the middle part of the inner cavity of the tank body 1, and the right side of the tank body 1 is provided with a synchronous traction mechanism 6 , the top of the inner cavity of the tank body 1 is provided wit...

Embodiment 2

[0050] Such as Figure 6 As shown, the preparation method specifically includes the following steps:

[0051] S1. Heating and melting: the raw material honey is input into the tank body 1 through the feed pipe, at this time, the two sliding sealing plates 51 are in a bonded state, and the inner cavity of the tank body 1 is sealed, and the raw material honey enters the tank body 1. , flow to the top of the two sliding sealing plates 51, then start the drive motor 3, after the drive motor 3 starts, drive a plurality of heating tubes 74 to rotate through the connecting shaft 71, the rotating sleeve 72 and the rotating disk 73, and then the raw honey is stirred and Heat treatment, stop the drive motor 3 after the stirring is completed;

[0052] S2. Transfer to the same chamber: the two-axis motor drives the two sliding sealing plates 51 to move away from each other, so that the raw honey falls into the top of the filter assembly 4, and the sliding sealing plates 51 are moved outw...

Embodiment 3

[0058] It should also be noted that when the clamping block 92 cannot enter the clamping groove 95 during the descending process, and the alignment can only be achieved after the subsequent reciprocating screw 85 drives the clamping block 92 to rotate, in order to prevent the filtering acceleration mechanism 8 from falling as a whole, the The filter assembly 4 exerts excessive pressure and causes the filter assembly 4 to deform. Therefore, when the above situation occurs, the spring 93 will be compressed and shortened, and at the same time, the inner shaft of the telescopic rod 91 will be driven back to the outer shaft of the telescopic rod 91 through the block 92 , and then buffer the filtering acceleration mechanism 8 and the locking mechanism 9 during the falling process, so as to avoid the deformation of the filter assembly 4 due to the falling pressure of the filtering accelerating mechanism 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com