Dispensing and curing device for lens of optical lens

A technology of optical lens and curing device, which is applied to the device for coating liquid on the surface, optics, optical components, etc., which can solve the problems of not having automatic lens feeding, etc., so as to prevent dust, ensure accurate contact surface, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

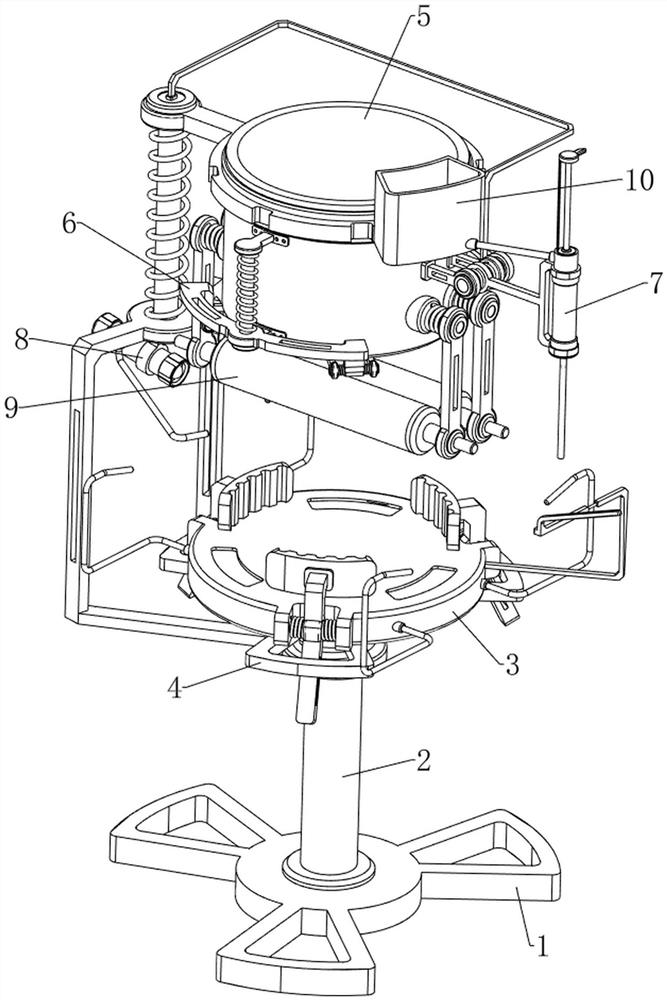

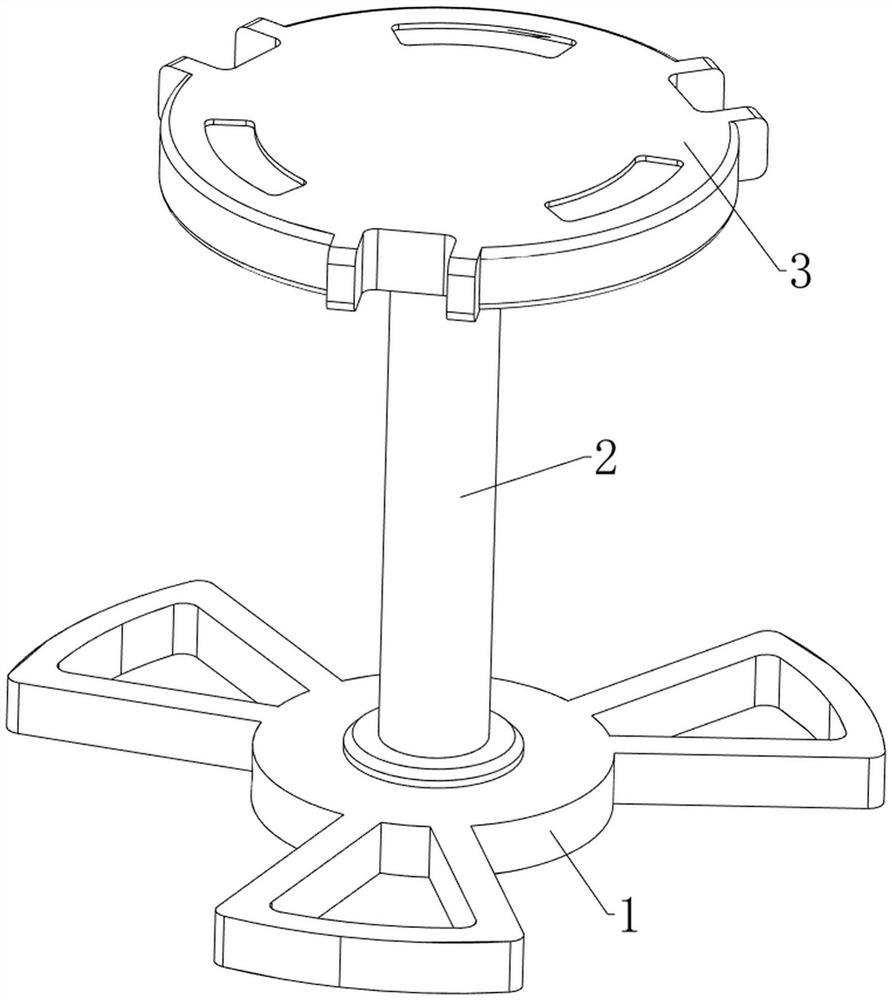

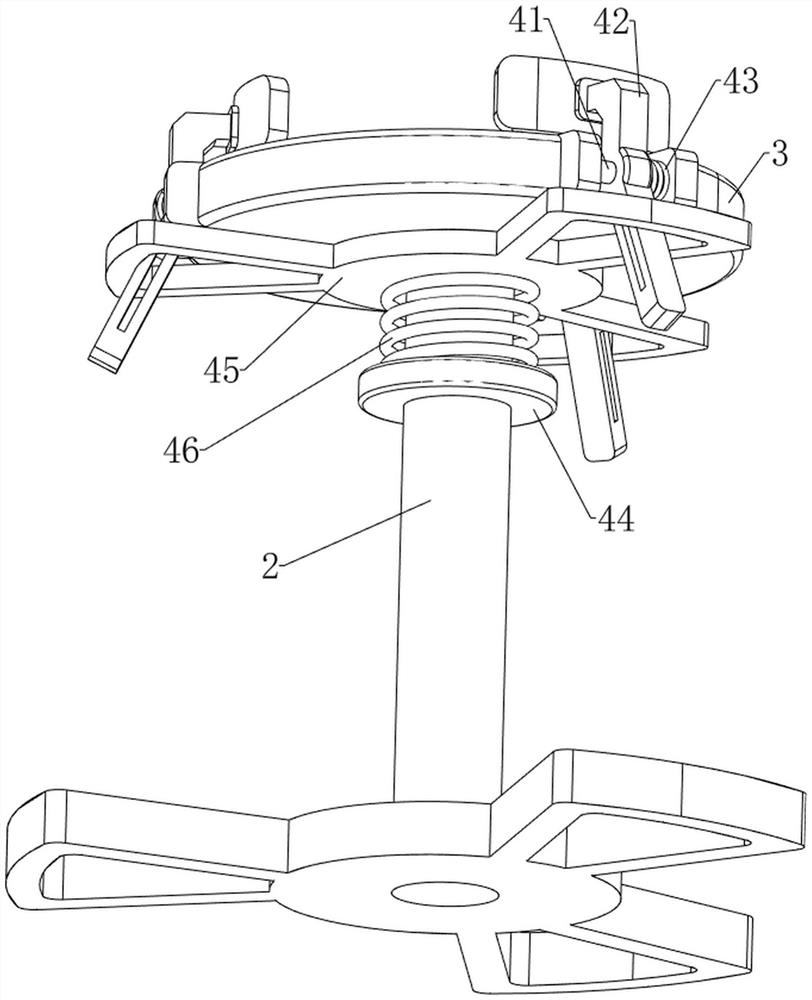

[0038] Dispensing and curing device for lens of optical lens, such as Figure 1-12 As shown, it includes a chassis 1, a fixing rod 2, a feeding tray 3, a positioning mechanism 4, a feeding mechanism 5, a clamping mechanism 6, a dispensing mechanism 7 and a curing mechanism 8, and a fixing rod 2 is welded in the middle of the top of the chassis 1. The top of the fixing rod 2 is provided with a feeding tray 3 for placing the convex lens. The fixing rod 2 is provided with a positioning mechanism 4 for clamping the convex lens. The positioning mechanism 4 is provided with a feeding mechanism 5 for accurately placing the concave mirror. The feeding mechanism 5. The front side is provided with a clamping mechanism 6 for holding the concave mirror, the right side of the feeding mechanism 5 is provided with a dispensing mechanism 7 for dripping glue on the surface of the convex lens, and the left side of the lower part of the feeding mechanism 5 is provided with a convex lens. The cur...

Embodiment 2

[0050] On the basis of Example 1, as figure 1 , Figure 13 , Figure 14 and Figure 15 As shown, it also includes a wiping mechanism 9. The wiping mechanism 9 includes a fifth connecting rod 91, a fifth connecting block 92, a fourth torsion spring 93, a wiping sponge 94, a sixth connecting rod 95 and a guide rod 96. 54 The left and right sides are symmetrically provided with fifth connecting rods 91 in front and back, each fifth connecting rod 91 is provided with a fifth connecting block 92 in a rotatable manner, and four fifth connecting blocks 92 are connected with the fifth connecting rod 91 on the same side. A fourth torsion spring 93 is connected between them, and a sixth connecting rod 95 is rotatably provided on the lower side of the four fifth connecting blocks 92. The wiping sponge 94 for wiping the surface of the convex lens, the left and right sides of the discharge tray 3 are symmetrically provided with guide rods 96 front and rear, and the four sixth connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com