Mixing device for producing and processing silicon PU court material

A mixing device and pitch technology, which is applied to the field of mixing devices for the production and processing of silicon PU pitch materials, can solve the problems of hanging on the stirring rod, too many material ratios, inconvenient feeding, etc. residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

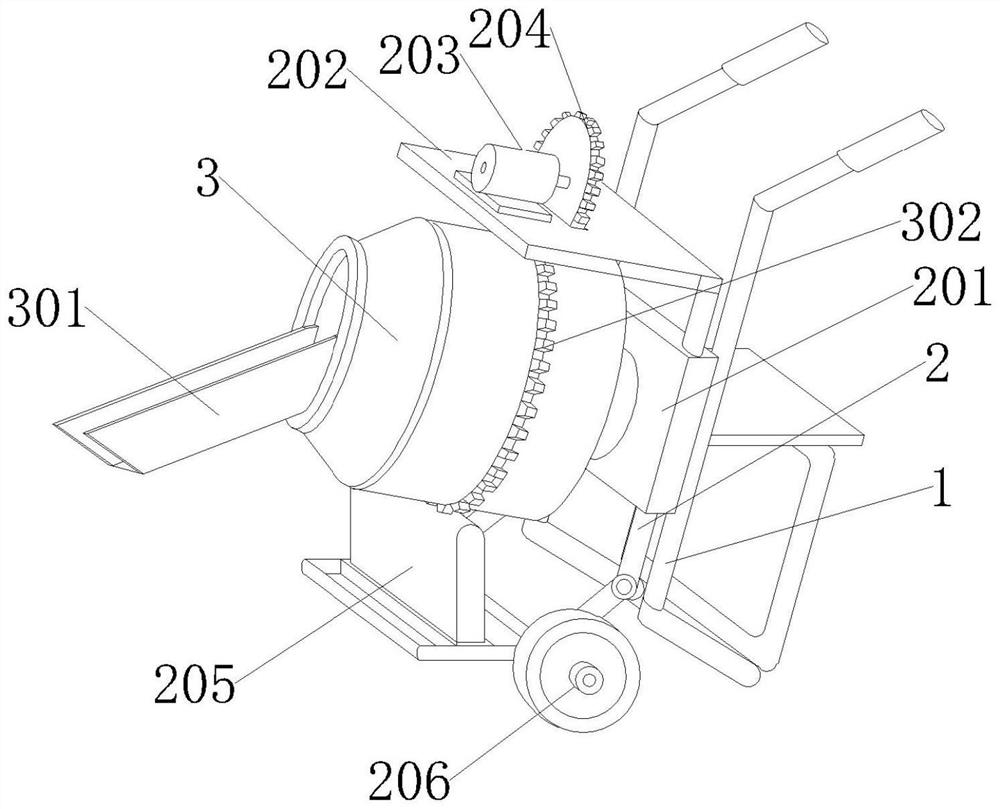

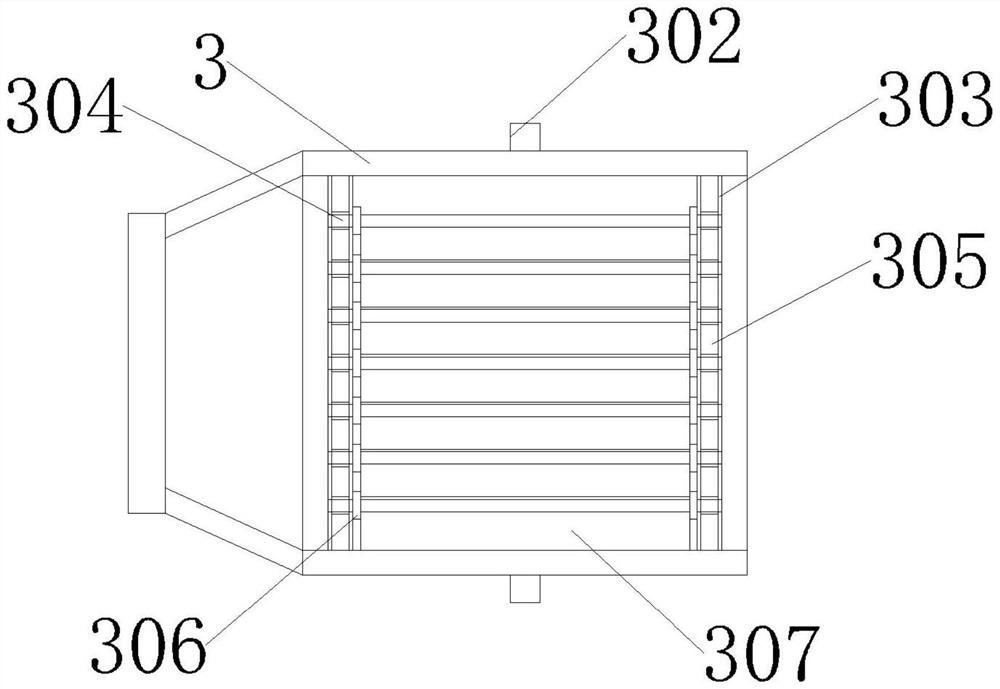

[0032] Embodiment 1: A mixing device for the production and processing of silicon PU court materials, including a support frame 1, the outer surface of the support frame 1 is fixedly connected with a mounting frame 2, and the outer surface of the mounting frame 2 is movably connected with a mixing barrel capable of stirring internal materials 3. A stirring rod 4 is movably connected inside the mixing barrel 3 .

[0033] One side of the mixing barrel 3 is fixedly connected with a discharge hopper 301, the outer surface of the mixing barrel 3 is fixedly connected with a rack 302, and the inner sides of the mixing barrel 3 are fixedly connected with a rotating slideway 303, and the internal movable blocks of the rotating slideway 303 305, the inside of the movable block 305 is fixedly connected with a sleeve ring 308, the inside of the movable block 305 is movably connected with a rotating shaft 304, the middle of the outer surface of the rotating shaft 304 is fixedly connected wi...

Embodiment 2

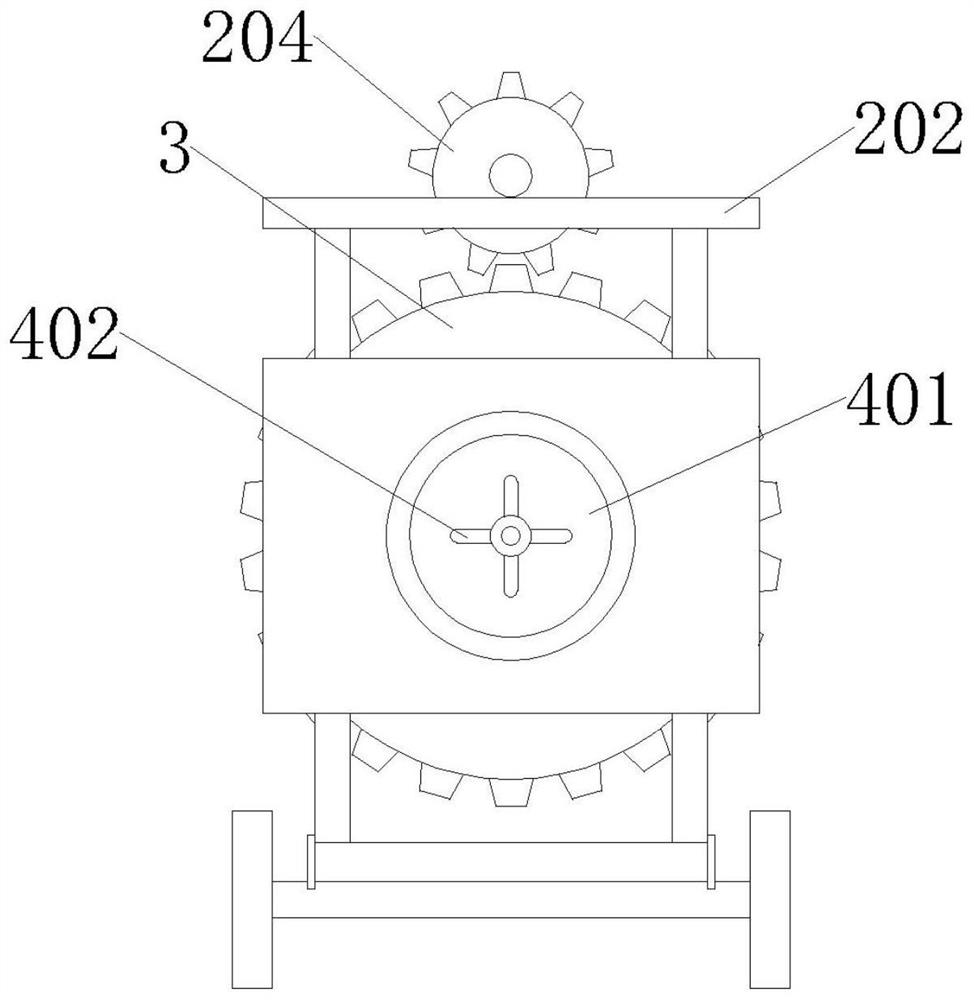

[0045] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the stirring rod 4 is located at the inner center of the mixing barrel 3 .

[0046] One side of the stirring rod 4 is fixedly connected with a support frame 405, the top and bottom of the stirring rod 4 are fixedly connected with a material rod 403, one side of the outer surface of the stirring rod 4 is movably connected with a threaded collar 404, and one side of the threaded collar 404 A rotating block 402 is fixedly connected, and a material stopper 401 is fixedly connected to the outer surface of the rotating block 402 .

[0047] The diameter of the material baffle 401 is larger than the diameter of the feed port of the mixing tank 3 , and one side of the material baffle 401 is provided with a silica gel layer.

[0048] One side of the outer surface of the stirring rod 4 is provided with threads, and the threads match the threads of the inner wall of the threaded collar 404 .

[0049] The in...

Embodiment 3

[0052] Embodiment 3: The difference between embodiment 3 and embodiment 2 is that the installation frame 2 is welded to the support frame 1 .

[0053] The outer surface of the mounting frame 2 is fixedly connected with a mounting plate 201, the top of the mounting plate 201 is fixedly connected with a power plate 202, the top of the power plate 202 is fixedly mounted with a motor 203, and the output end of the motor 203 is fixedly connected with a gear 204. The bottom of the support block 205 is rotatably connected with a support block 205, and the two sides of the support block 205 are rotatably connected with moving wheels 206.

[0054] Wherein, the inside of the mounting plate 201 is connected with the feeding port of the mixing tank 3 .

[0055] Wherein, the bottom of the gear 204 meshes with the rack 302 .

[0056] Wherein, the installation frame 2 is connected with the support block 205 through a damping shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com