Railway vehicle sanding control method

A control method and rail vehicle technology, applied in the field of rail vehicle sanding control, can solve problems such as excessive use of sand, increased sand procurement costs and manual maintenance costs, etc., to reduce the increase in procurement costs, increase the maintenance cycle of sand addition, and improve operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

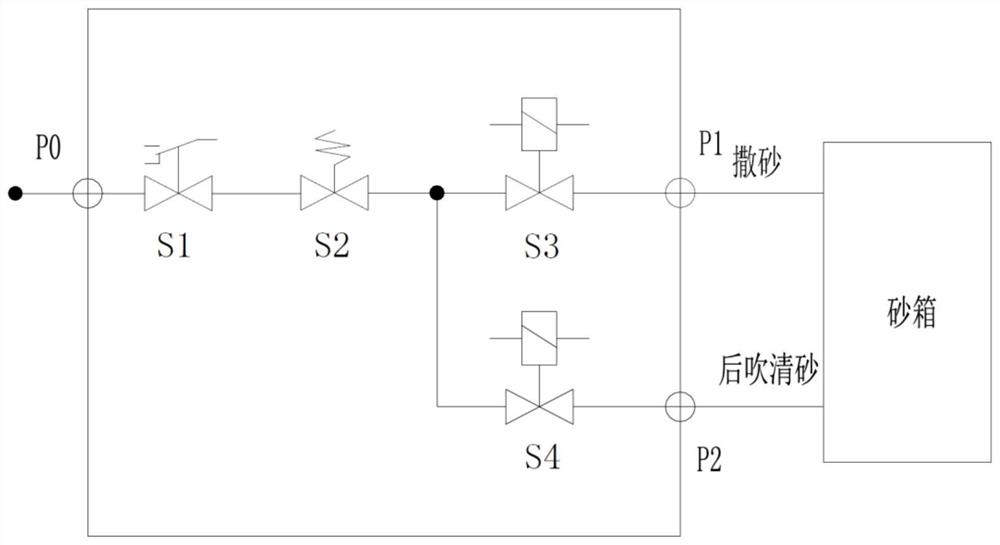

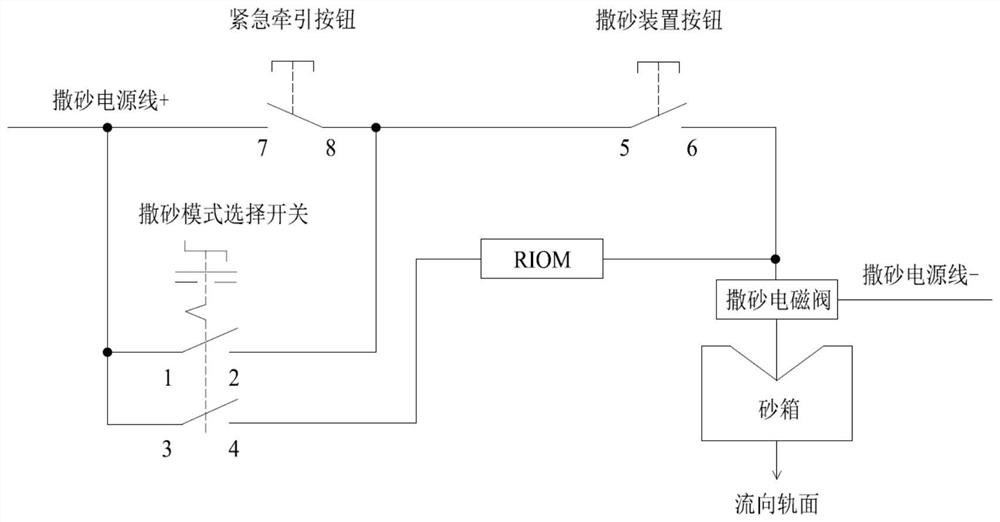

[0023] combine figure 1 with figure 2 Describe this embodiment, a rail vehicle sanding control method, the method is specifically implemented by the following process:

[0024] Take the vehicle marshalling of a certain line of Chongqing Metro as an example to illustrate. The full list is a formation of 6 vehicles: "=Mc1+Mp1+M1-M2+Mp2+Mc2=", when the Mc1 vehicle is the master, the Mc1, Mp1, and M1 vehicles perform sanding; when the Mc2 vehicle is the master, the Mc2, Mp2, M2 vehicles perform sanding.

[0025] Sanding control is divided into automatic sanding and manual sanding.

[0026] Automatic sanding conditions and instruction transmission:

[0027] Braking level ≥ 85% of the maximum common braking and continuous sliding (single-axis or multi-axis) for more than 3s;

[0028] During emergency braking and coasting (single or multiple axles).

[0029] When the network system detects any one of the above two trigger conditions, the network will issue a sand spreading com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com