Radiographic detection method for complex steel castings with different thicknesses

A technology for radiographic inspection and steel castings, which is applied in the field of radiographic inspection of thick and complex steel castings, can solve problems such as affecting inspection efficiency and effect, increase in scrap rate, and excessive radiation absorption, so as to improve inspection efficiency and inspection effect, The effect of reducing the formation of waste flakes and equalizing the intensity of rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

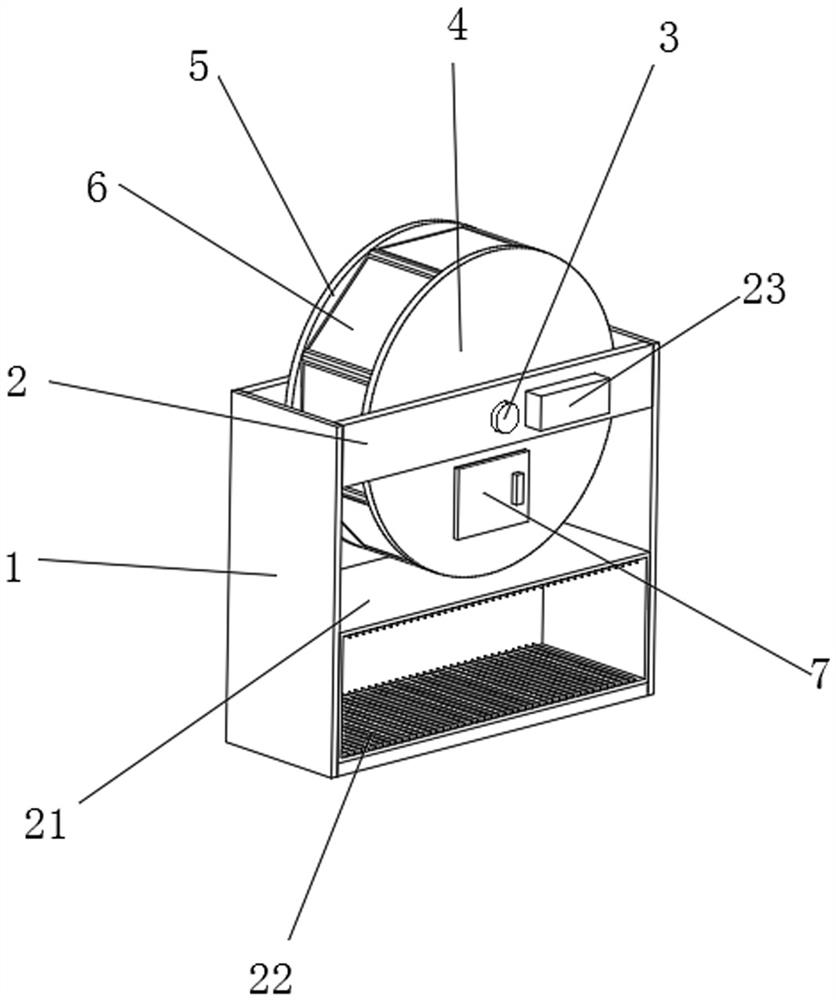

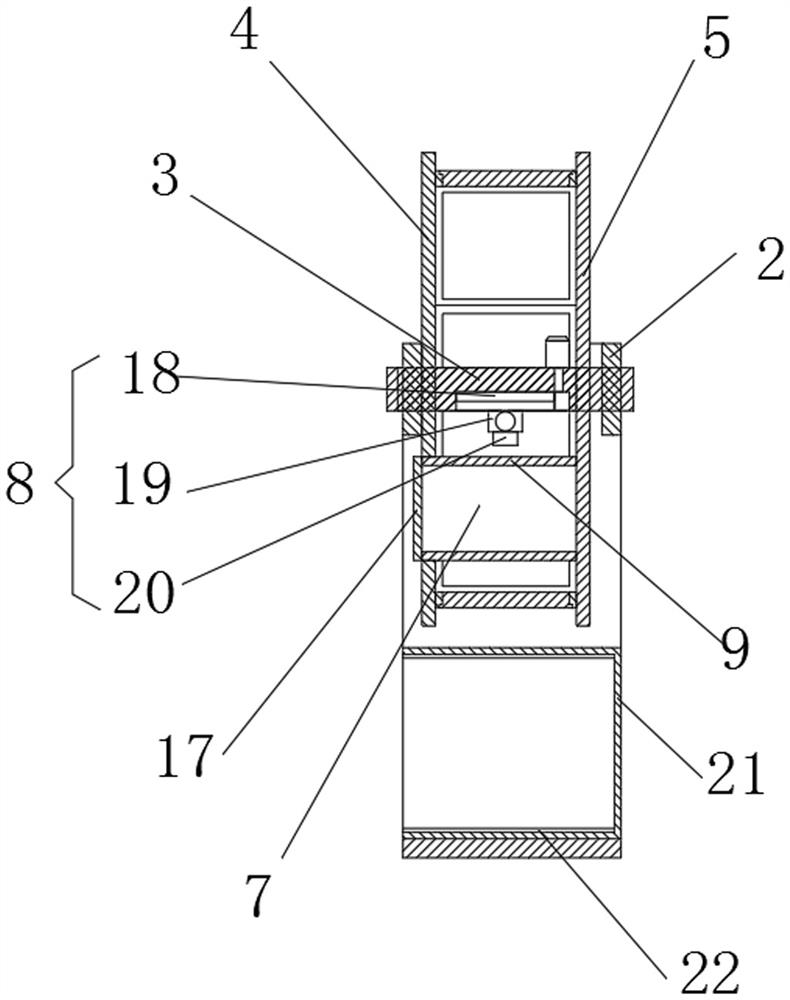

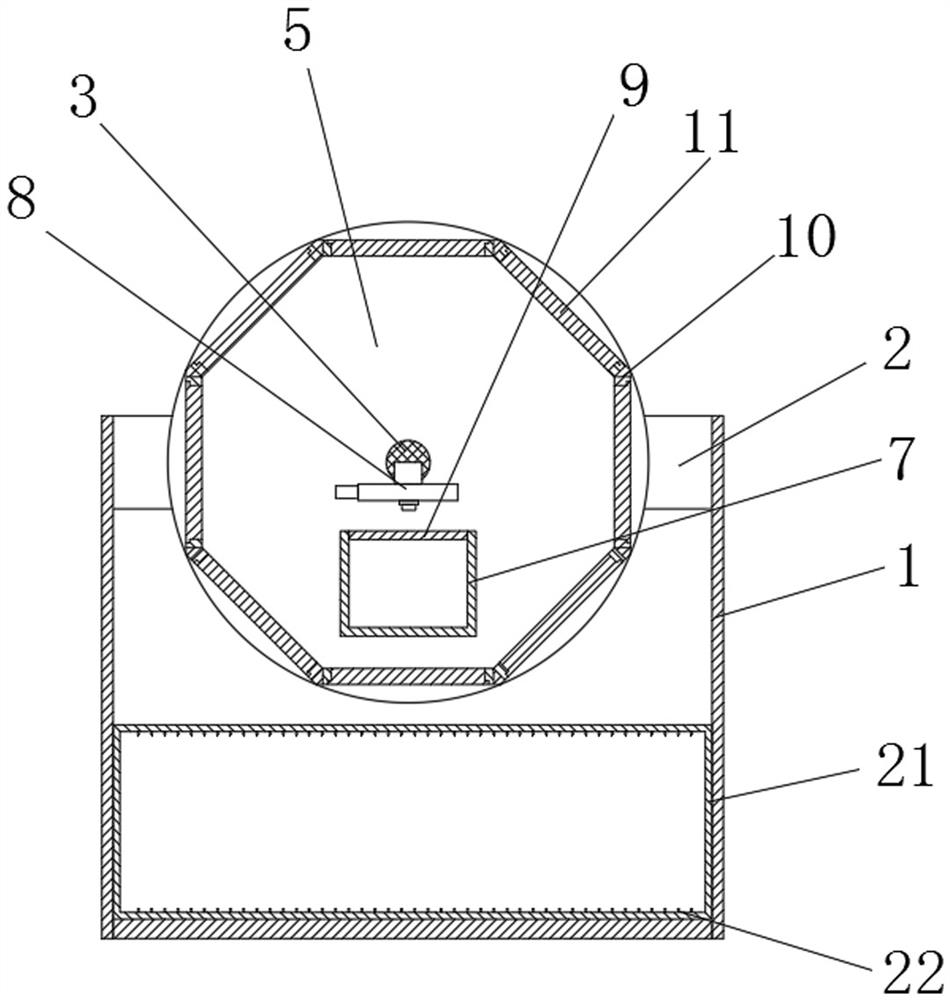

[0039] see Figure 1-4, a ray detection method for complex steel castings with unequal thickness, the method is realized based on a ray detection device for complex steel castings with unequal thickness, the ray detection device for complex steel castings with equal thickness includes a detection frame 1, The front and rear sides of the upper end of the detection frame 1 are provided with installation beams 2, the center of the installation beams 2 on both sides is fixedly connected with the installation shaft 3, the outer surface of the installation shaft 3 is fixedly connected with the fixed end plate 4 near the front end, and the fixed end plate 4 The lower end is provided with a workpiece placement bin 7, the front end of the workpiece placement bin 7 is set through the fixed end plate 4, and the lower end of the middle section of the installation shaft 3 is provided with a radiation transillumination mechanism 8, and the radiation transillumination mechanism 8 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com