Cable joint with fault sensing structure and fault sensing system of cable joint

A cable joint and cable joint technology, applied in cable joints, electrical connection testing and other directions, can solve problems such as partial discharge, high-voltage cable accidents, melting of insulating tape, etc., to facilitate preparation and maintenance, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

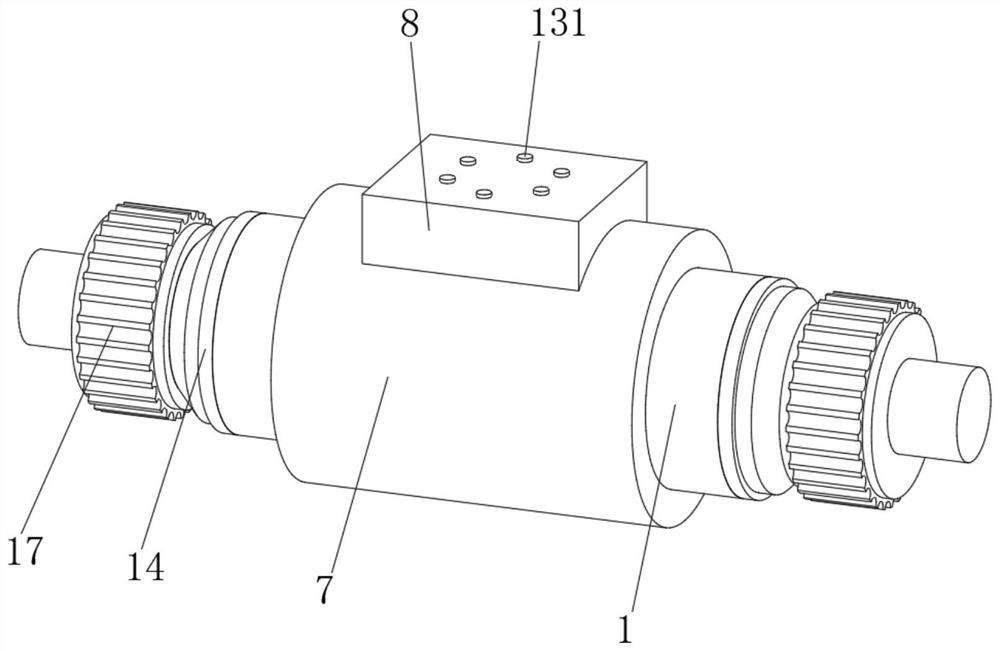

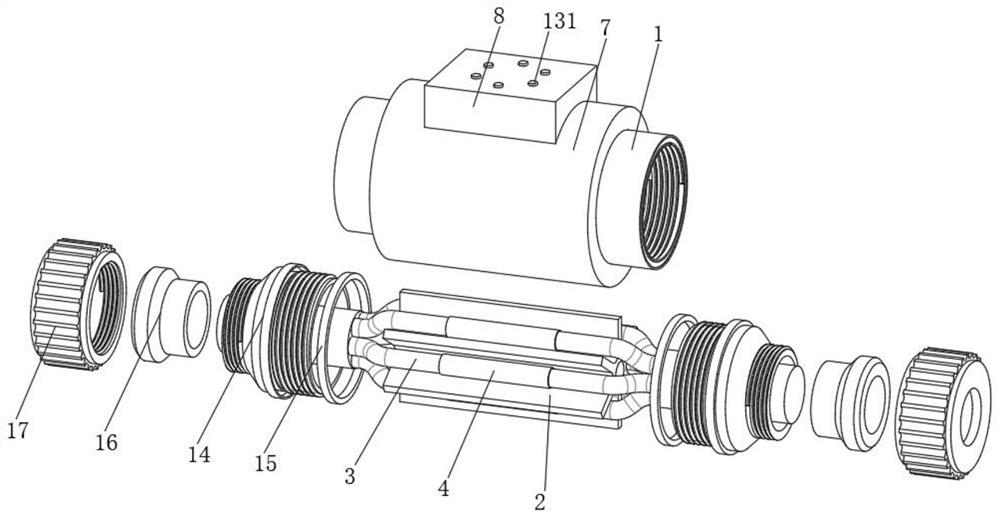

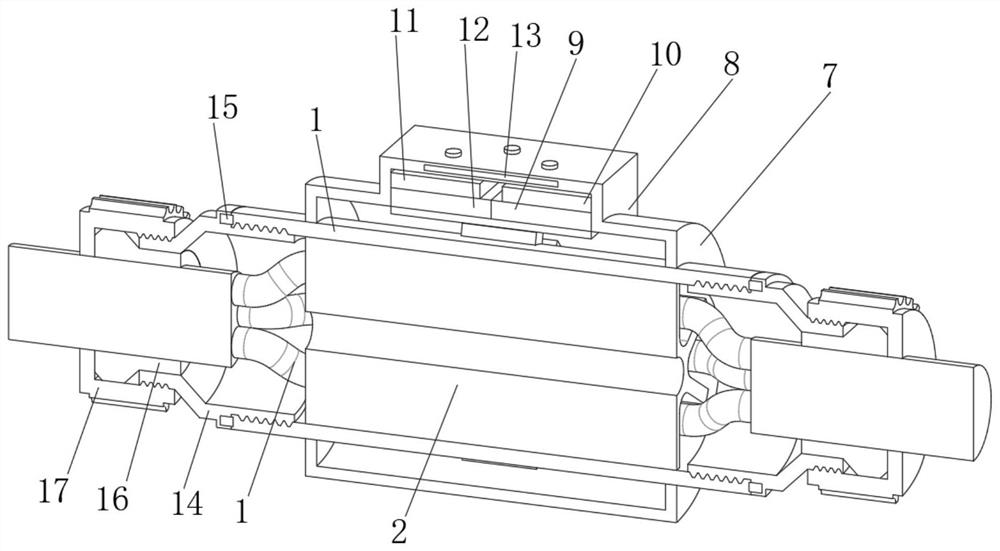

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: a cable connector with a fault sensing structure, including an inner casing 1, a partition device 2 is placed inside the inner casing 1, a cable connector 3 is placed inside the partition device 2, and the partition device There is a weight-reducing hole in the middle of 2, and there are six partitions symmetrically distributed in the outer center of the partition device 2, which separate the cable joints 3 independently. By setting the partition device 2, the cable joints 3 Separate them one by one to avoid a virtual connection of one cable joint 3. After heating, melt the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com