Automatic assembling equipment for tulip contacts for circuit breakers

A plum blossom contact, automatic assembly technology, applied in the direction of circuits, electrical components, electric switches, etc., can solve the problems of inability to batch output, low work efficiency, single station installation of plum blossom contacts, etc., to shorten working time and improve assembly efficiency Low, solve the effect of spring tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

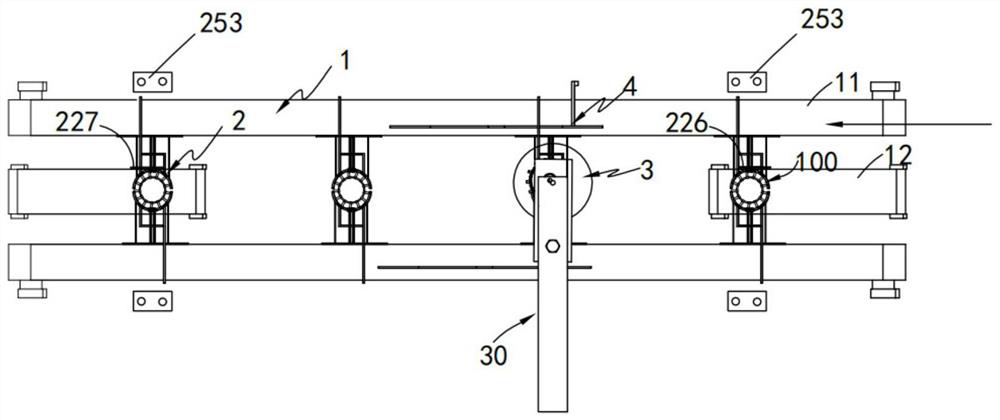

[0057] Such as figure 1 Shown, a kind of circuit breaker plum blossom contact automatic assembly equipment, comprises:

[0058] The conveying device 1, the conveying device 1 includes a conveying mechanism a11 and a conveying mechanism b12 arranged side by side, the conveying mechanism a11 is arranged in two groups and arranged symmetrically on both sides of the conveying mechanism b12;

[0059] Clamping device 2, the clamping device 2 is arranged on the transmission mechanism a11 and several groups are arrayed in sequence along the transmission direction of the transmission mechanism a11, and the two sets of clamping devices 2 correspondingly arranged complete the alignment of the transmission mechanism a11 The quincunx contact part 100 on the transmission mechanism b12 is clamped;

[0060] The spring installation device 3, the spring installation device 3 is arranged at the rear end of the transmission mechanism b12, which includes a sleeve spring installed on the frame ass...

Embodiment 2

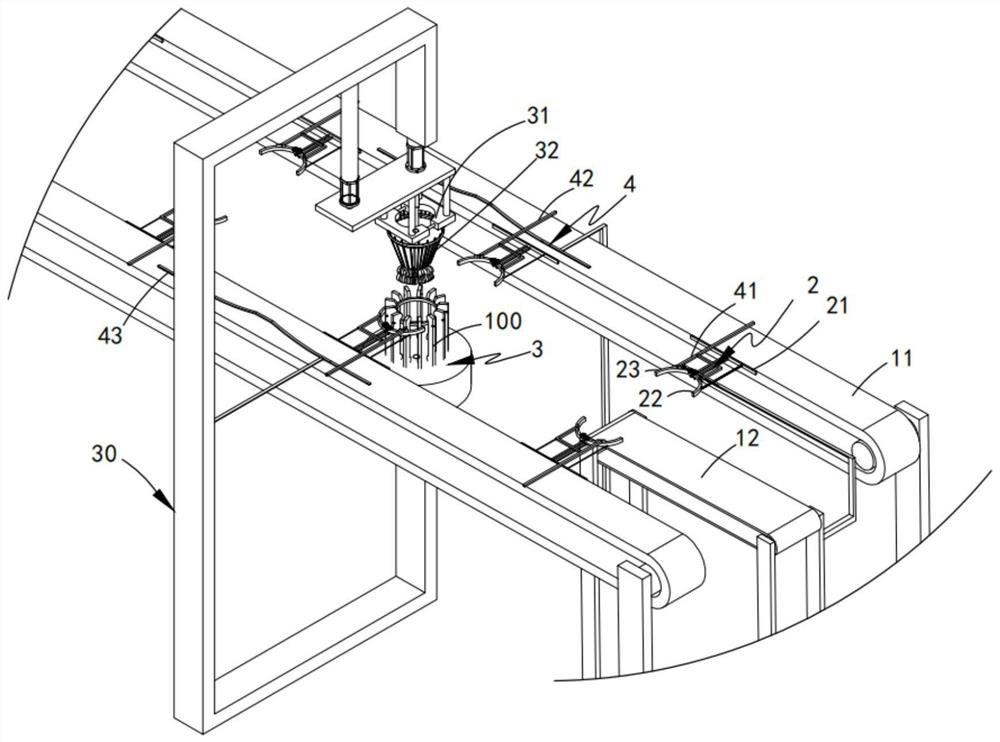

[0105] Such as Figure 1 to Figure 3 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0106] further, such as Figure 4 As shown, the adjusting device 4 includes:

[0107] Lifting component 41, the lifting component 41 is set in two groups and correspondingly arranged in the groove 220 opened on the hoop 222, the lifting component 41 includes an elastic unit c411 vertically arranged in the groove 220 And a top support ring 412 installed above the elastic unit c411 and matched with the outer circumference of the plum blossom contact part 100;

[0108] An external transmission rod 42, the external transmission rod 42 is a multi-stage structure and its ends are respectively used to connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com