Integrated separator

A separator and static separation technology, applied in the separation method, solid separation, dispersed particle separation, etc., can solve the problem of the overall layout height of the cement plant of the separator and the huge construction cost, and achieve the effect of minimizing the building height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

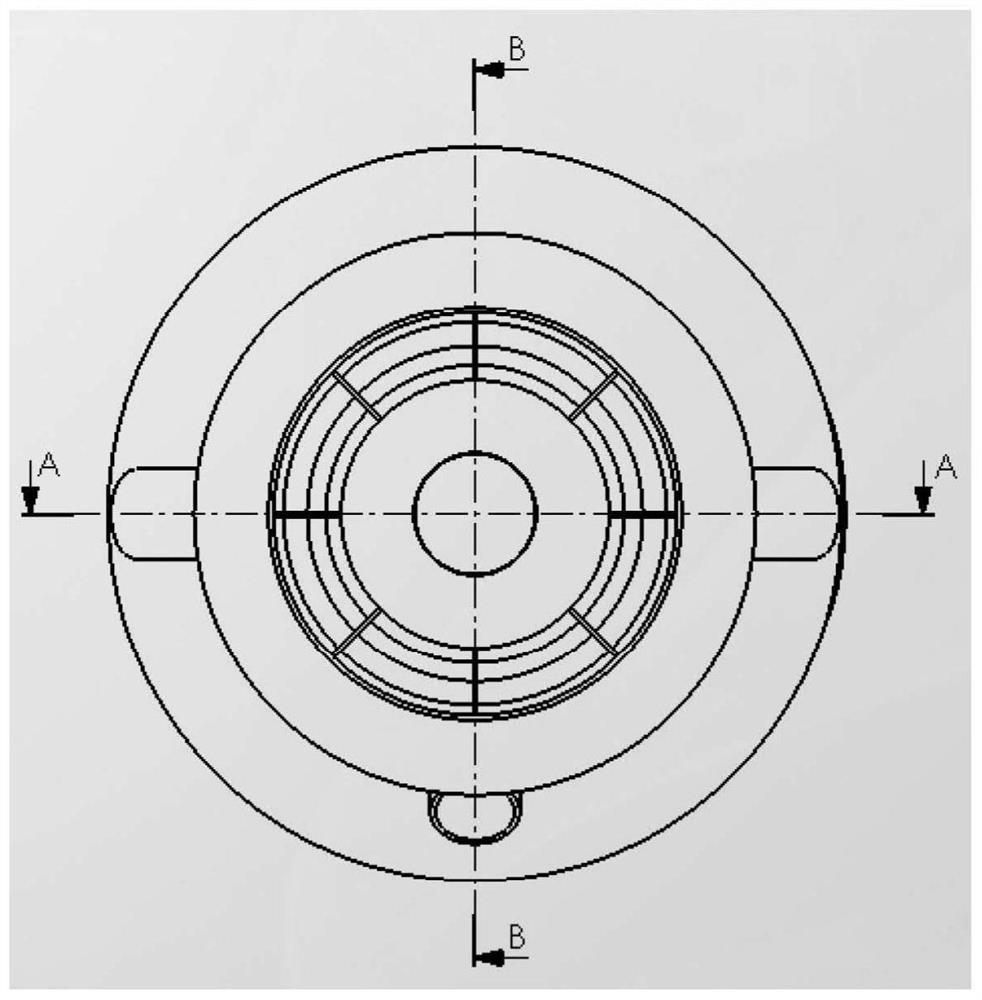

[0035] figure 1 The integrated separator according to the invention is schematically shown from a top view, showing a feed chute, a waste chute and a housing with a retaining rod for holding a frustum of a cone.

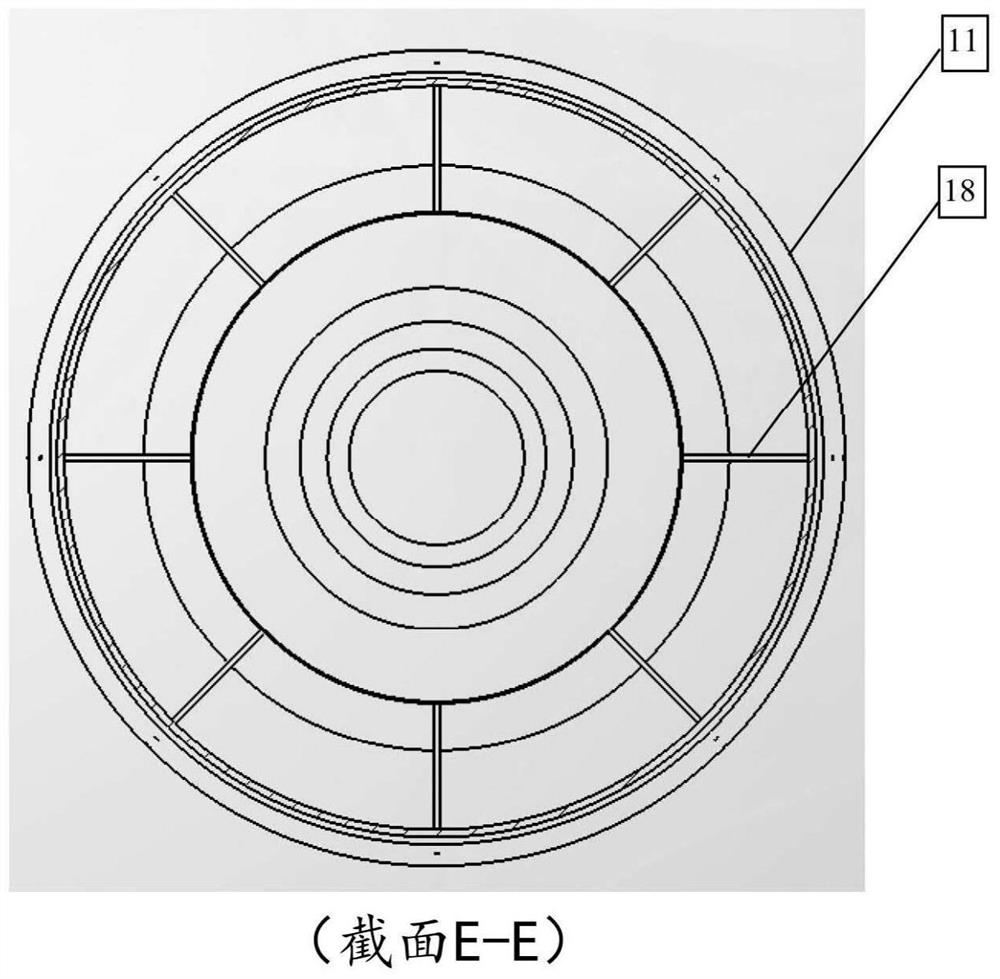

[0036] figure 2 The frustum of the cone according to the invention is schematically shown from a top view, and how the frustum of the cone is held in its position by the holding rod.

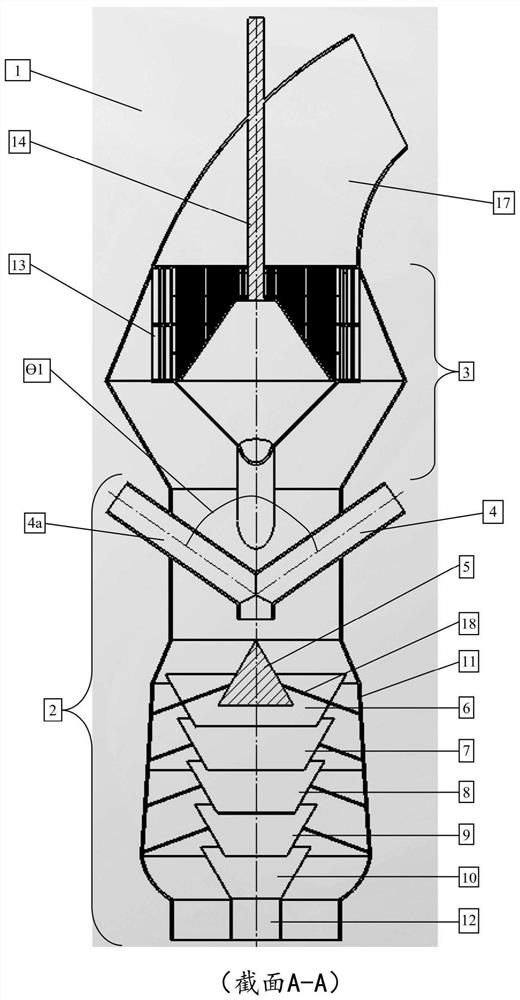

[0037] image 3 An integrated separator 1 for separating coarse and fine particles in a cement manufacturing process is schematically shown. Integrated separator 1 includes:

[0038] - static separator 2,

[0039] - a dynamic separator 3 arranged in an uppermost position relative to the static separator 2, and

[0040] The static separator 2 comprises a housing 11 , a defocusing cone 5 and a first inverted frustum cone 6 . The defocusing cone 5 is arranged adjacent to the first inverted frustum 6 by means of a holding rod 18 . A holding rod 18 is connected to the first inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com