Making method of indoor handmade fine dried noodles

A production method and noodle technology, which is applied in the field of food processing, can solve the problems of ramen noodles being shaped, dropped, and not in compliance with health and safety permits, and achieve the effects of improving work efficiency, avoiding waste, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

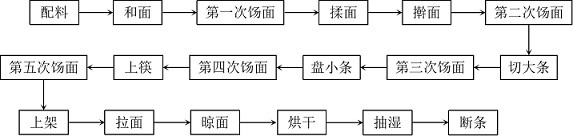

Image

Examples

Embodiment 1

[0100] A method for making indoor handmade dried noodles, comprising the steps of:

[0101] (1) Ingredients:

[0102] Pour 25kg of flour into a stainless steel basin, then weigh the following raw materials according to weight percentage: 2.5% edible salt, 2% purple sweet potato, 50% water, add the above-mentioned weighed raw materials into the flour in turn, and stir evenly;

[0103] (2) Kneading:

[0104] Pour the flour in the proportion in step (1) into the dough mixer, turn on the dough mixer, let the dough mixer rotate, and then keep the dough mixer running until it comes out, and control the time and frequency of pouring salt water , Cooperate with the forward and reverse of the dough mixer, so that the dough can be even and thorough after 15 minutes, and the dough can be placed after the stickiness and softness of the dough meet the requirements;

[0105] (3) The first noodle meal:

[0106] Put the kneaded dough in a stainless steel basin, press, knead, and pat the do...

Embodiment 2

[0140] A method for making indoor handmade dried noodles, comprising the steps of:

[0141] (1) Ingredients:

[0142] Pour 25kg of flour into a stainless steel basin, then weigh the following raw materials according to weight percentage: 3.75% edible salt, 4% spinach, and 60% water. The above-mentioned raw materials weighed are added to the flour in turn, and stirred evenly;

[0143] (2) Kneading:

[0144] Pour the flour in the proportion in step (1) into the dough mixer, turn on the dough mixer, let the dough mixer rotate, and then keep the dough mixer running until it comes out, and control the time and frequency of pouring salt water , Cooperate with the forward and reverse of the dough mixer, so that the dough can be even and thorough after 22.5 minutes, and the dough can be placed after the stickiness and softness of the dough meet the requirements;

[0145] (3) The first noodle meal:

[0146] Put the kneaded dough in a stainless steel basin, press, knead, and beat the...

Embodiment 3

[0180] A method for making indoor handmade dried noodles, comprising the steps of:

[0181] (1) Ingredients:

[0182]Pour 25kg flour into a stainless steel basin, then weigh the following raw materials according to weight percentage: 5% edible salt, 6% pumpkin, and 70% water, add the above-mentioned raw materials into the flour in turn, and stir evenly;

[0183] (2) Kneading:

[0184] Pour the flour in the proportion in step (1) into the dough mixer, turn on the dough mixer, let the dough mixer rotate, and then keep the dough mixer running until it comes out, and control the time and frequency of pouring salt water , Cooperate with the forward and reverse of the dough mixer, so that the dough can be even and thorough after 30 minutes, and the dough can be placed after the stickiness and softness of the dough meet the requirements;

[0185] (3) The first noodle meal:

[0186] Put the kneaded dough in a stainless steel basin, press, knead, and pat the dough with your palm or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com