Heat-not-burn original-tobacco-flavor fuming feed liquid, fuming particle and preparation method of fuming particle

A heat-not-burn, smoke-emitting particle technology, applied to tobacco, tobacco preparation, tobacco processing, etc., can solve problems such as roughness and weak aroma, and achieve the effect of lasting aroma, mellow bottom aroma, and improving satisfaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

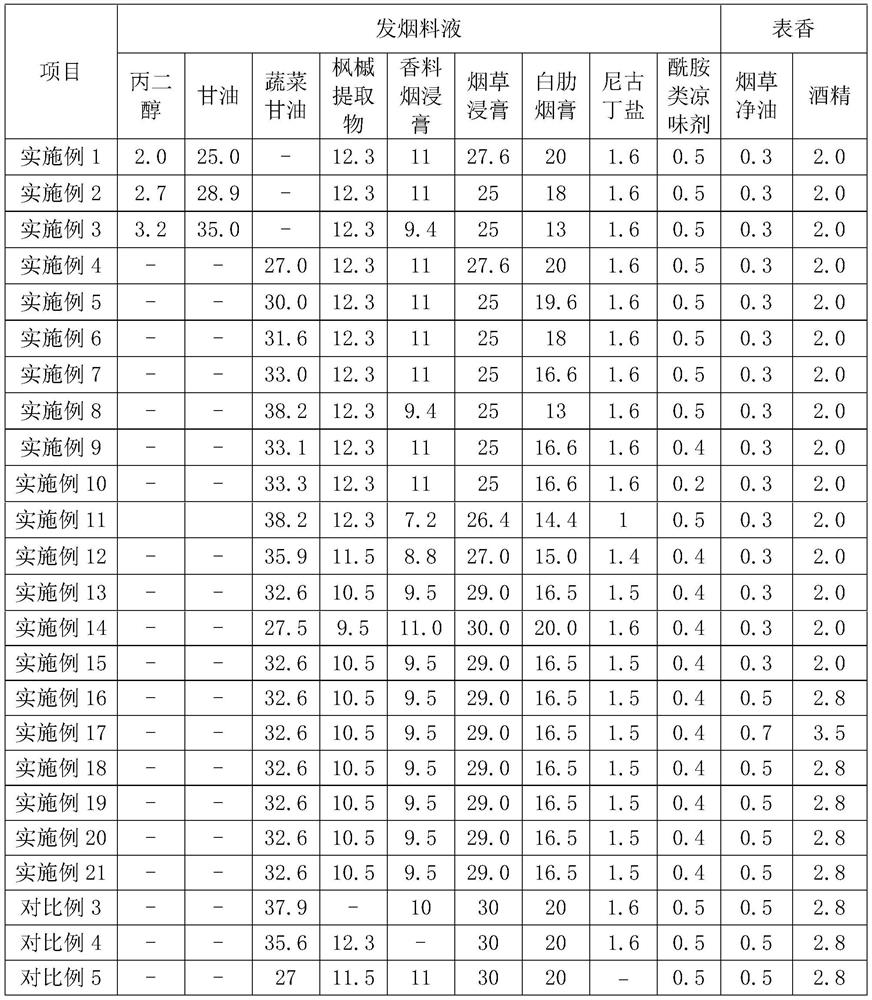

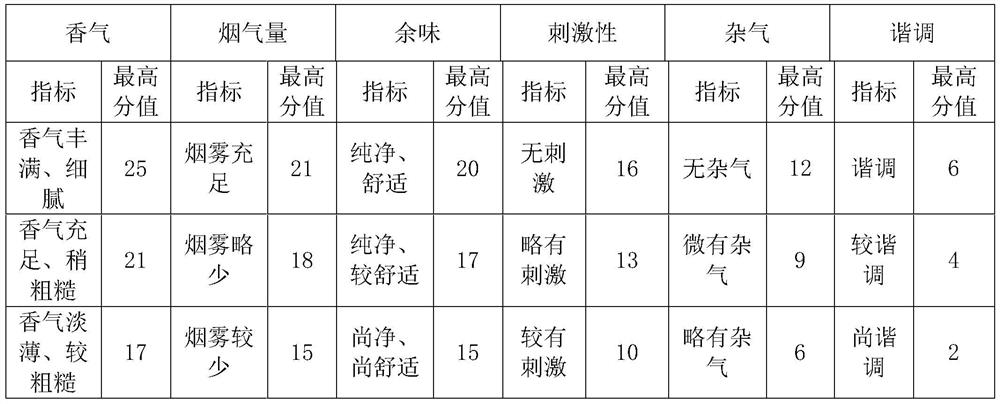

Examples

preparation example Construction

[0036] A method for preparing heat-not-burn fuming particles, comprising the steps of:

[0037] (1) Weigh the carrier and the fuming material liquid according to the mass ratio of 1:1, put them into the mixing container for mixing in turn, let the carrier stand to fully absorb the fuming material liquid after mixing, sieve, and take a particle size of 20- 50 mesh particles for follow-up tests;

[0038] (2) Put the granules prepared in (1) into a drying container for drying until the water content of the granules is 15%, and obtain semi-finished fuming granules;

[0039](3) Mix tobacco absolute and alcohol, add it into the semi-finished product of smoking particles by spraying and flavoring after mixing, and then add the wrapping agent according to the mass ratio of semi-finished product of smoking particles: wrapping agent to block the flavor, and obtain the fragrance. smoke particles.

Embodiment 18

[0040] The difference between Example 18 and Example 17 is that the ratio of the carrier to the smoking liquid is 1:1.1.

Embodiment 19

[0041] The difference between Example 19 and Example 17 is that the ratio of the carrier to the smoking liquid is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com