Cheese powder essence and preparation method thereof

A powder essence and cheese technology, which is applied in the field of flavor and fragrance, can solve problems such as coordination, poor high temperature stability, high use cost, and aroma loss, and achieve the effects of good fluidity, low preparation temperature, and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

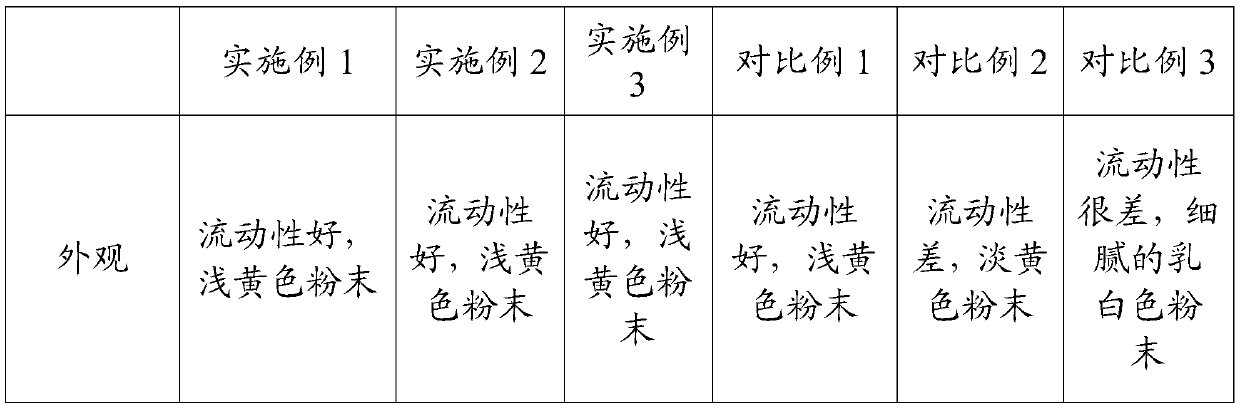

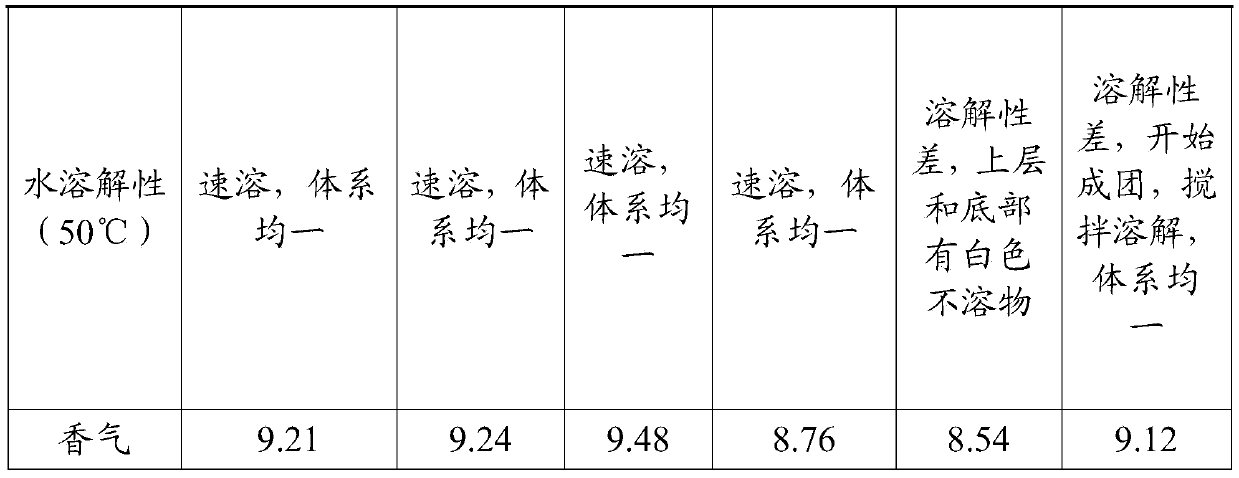

Examples

Embodiment 1

[0053] A cheese powder flavor, in parts by weight, prepared from raw materials including the following components:

[0054] 3 parts by weight of sulfur-containing flavor ester composition, 0.03 parts by weight of glycerol monooleate, 60 parts by weight of casein hydrolysate, 3 parts by weight of sodium starch octenyl succinate, 2 parts by weight of sodium caseinate, and 79.97 parts by weight of maltodextrin Parts by weight, 12 parts by weight of water.

[0055] The preparation method includes the following steps:

[0056] (1) Weigh the casein hydrolysate and water into a clean stainless steel tank I according to the above ratio;

[0057] (2) Weigh maltodextrin, sodium starch octenyl succinate and sodium caseinate into the mixer according to the above-mentioned proportions. After mixing uniformly, slowly add them to stainless steel tank I under stirring, and stir at room temperature until completely dissolved, then Heat to 60~65℃ to keep warm, it is water phase;

[0058] (3) Weigh the ...

Embodiment 2

[0062] A cheese powder flavor, in parts by weight, prepared from raw materials including the following components:

[0063] 4 parts by weight of sulfur-containing flavor ester composition, 0.04 parts by weight of glycerol monooleate, 55 parts by weight of casein hydrolysate, 4 parts by weight of sodium starch octenyl succinate, 2.5 parts by weight of sodium caseinate, and 78.46 of maltodextrin Parts by weight, 16 parts by weight of water.

[0064] The preparation steps are the same as in Example 1.

Embodiment 3

[0066] A cheese powder flavor, in parts by weight, prepared from raw materials including the following components:

[0067] 5 parts by weight of sulfur-containing flavor ester composition, 0.05 parts by weight of glycerol monooleate, 50 parts by weight of casein hydrolysate, 5 parts by weight of sodium starch octenyl succinate, 3 parts by weight of sodium caseinate, and 76.95 parts of maltodextrin Parts by weight, 20 parts by weight of water.

[0068] The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com