Sulfur-containing flavor ester composition and its preparation method and cheese essence

A technology of composition and flavor ester, which is applied in the field of flavors and fragrances, can solve the problems of top aroma irritation, large amount of addition, and aroma distortion, and achieve the effect of improving high temperature stability, good high temperature stability, and flavor coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

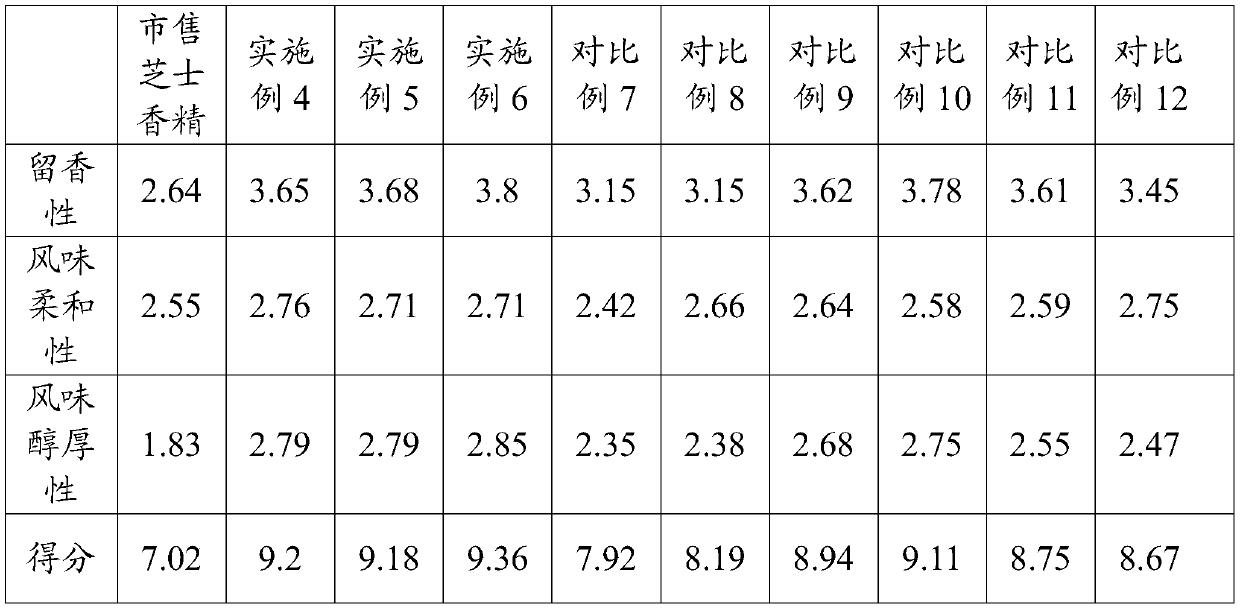

Examples

Embodiment 1

[0035] A sulfur-containing flavor ester composition prepared by the following method:

[0036] (1) Using anhydrous butter and 3-methylthiopropanol as raw materials, add 300U of Rhizomucor miehei lipase Lipozyme RM IM to each gram of raw materials and carry out enzymatic hydrolysis reaction at 52°C for 6 hours to obtain Product, wherein the addition of 3-methylthiopropanol is 30% of the quality of anhydrous cream;

[0037] (2) The enzymolysis product obtained in step (1) is subjected to secondary molecular distillation with a secondary molecular distillation device 2XMDS80, and the secondary molecular distillation includes I-level molecular distillation and II-level molecular distillation, wherein the enzymolyzed product is first subjected to I-level molecular distillation Molecular distillation, the vacuum of grade I molecular distillation is 32.7Pa, after removing the fractions in the temperature range below 70°C, continue to carry out grade II molecular distillation; the vac...

Embodiment 2

[0039] A sulfur-containing flavor ester composition prepared by the following method:

[0040] (1) Using anhydrous butter and 3-methylthiopropanol as raw materials, add 200 U of Rhizomucor miehei lipase Lipozyme RM IM to each gram of raw materials and carry out enzymatic hydrolysis reaction at 55°C for 5 hours to obtain Product, wherein the addition of 3-methylthiopropanol is 36% of the quality of anhydrous cream;

[0041] (2) The enzymolysis product obtained in step (1) is subjected to secondary molecular distillation with a secondary molecular distillation device 2XMDS80, and the secondary molecular distillation includes I-level molecular distillation and II-level molecular distillation, wherein the enzymolyzed product is first subjected to I-level molecular distillation Molecular distillation, the vacuum degree of the first-stage molecular distillation is 40Pa, and the second-stage molecular distillation is continued after removing the fraction at a temperature below 70°C; ...

Embodiment 3

[0043] A sulfur-containing flavor ester composition prepared by the following method:

[0044] (1) Using anhydrous butter and 3-methylthiopropanol as raw materials, add 400 U of Rhizomucor miehei lipase Lipozyme RM IM to each gram of raw materials and carry out enzymatic hydrolysis reaction at 50°C for 7 hours to obtain Product, wherein the addition of 3-methylthiopropanol is 33% of the quality of anhydrous cream;

[0045] (2) The enzymolysis product obtained in step (1) is subjected to secondary molecular distillation with a secondary molecular distillation device 2XMDS80, and the secondary molecular distillation includes I-level molecular distillation and II-level molecular distillation, wherein the enzymolyzed product is first subjected to I-level molecular distillation Molecular distillation, the vacuum degree of the first-stage molecular distillation is 30Pa, after removing the fraction at a temperature below 70°C, proceed to the second-stage molecular distillation; the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com