Intelligent efficient three-phase separator

A technology of three-phase separator and separator, which is applied in the direction of filtration separation, separation method, and dispersed particle separation, etc., which can solve the problems of inconvenient and inconvenient sludge transportation, and inability to export air filtration, etc., to achieve Avoid the effect of easy opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

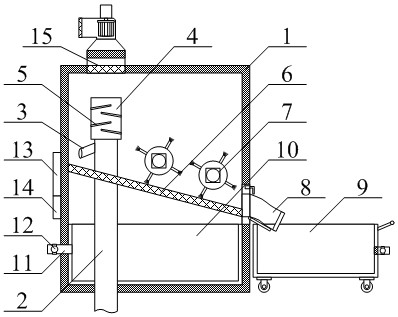

[0041] as attached figure 1 And attached figure 2As shown, the present invention provides an intelligent high-efficiency three-phase separator, including a separator main body 1, a feed pipe 2, a liquid outlet pipe 3, a gas discharge frame 4, a gas buffer plate 5, a sludge separation screen 6, and auxiliary isolation Conveyor frame structure 7, sludge export protection frame structure 8, sludge collection transport frame structure 9, water liquid collection box 10, water liquid export pipe 11, water liquid export valve 12, control panel 13, controller 14 and gas export filter frame structure 15, the feed pipe 2 is plugged into the left side of the separator main body 1; the liquid outlet pipe 3 is plugged into the upper left side of the feed pipe 2; the gas discharge frame 4 Installed on the upper part of the feed pipe 2; the gas buffer plate 5 is screw-installed on the inside of the gas discharge frame 4; the sludge separation screen 6 is installed in the middle position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com