Mold for producing centrifugal fan blade

A technology of centrifugal fan blades and molds, which is used in household appliances, other household appliances, applications, etc., can solve the problems of different strength, easy damage of blades, and long overall structure of centrifugal blades, so as to achieve the process of improving quality and demoulding handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

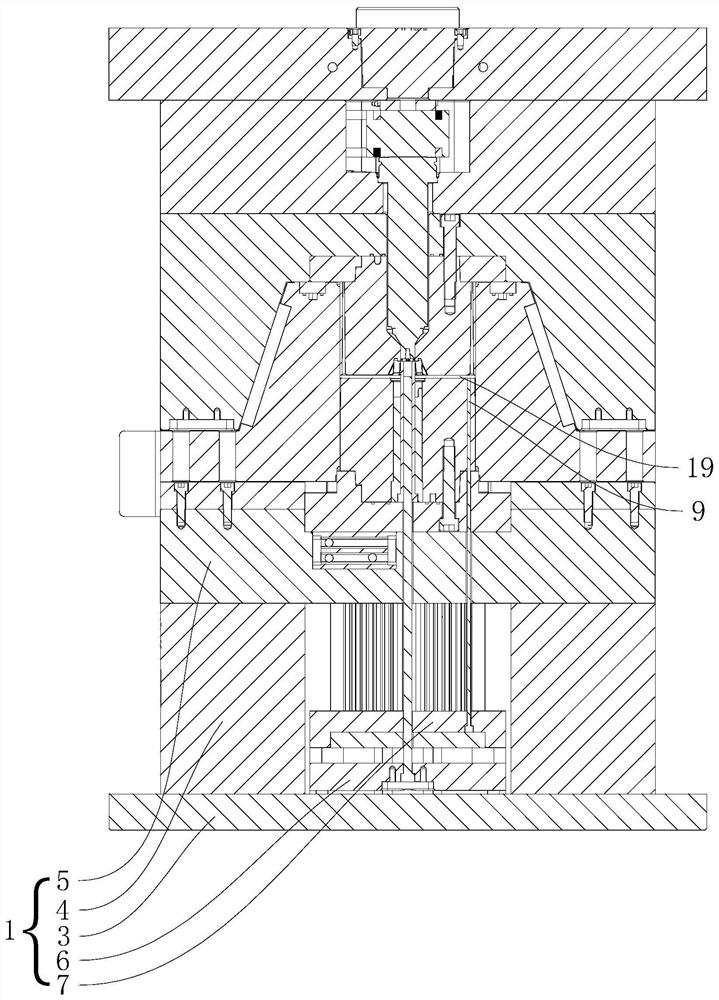

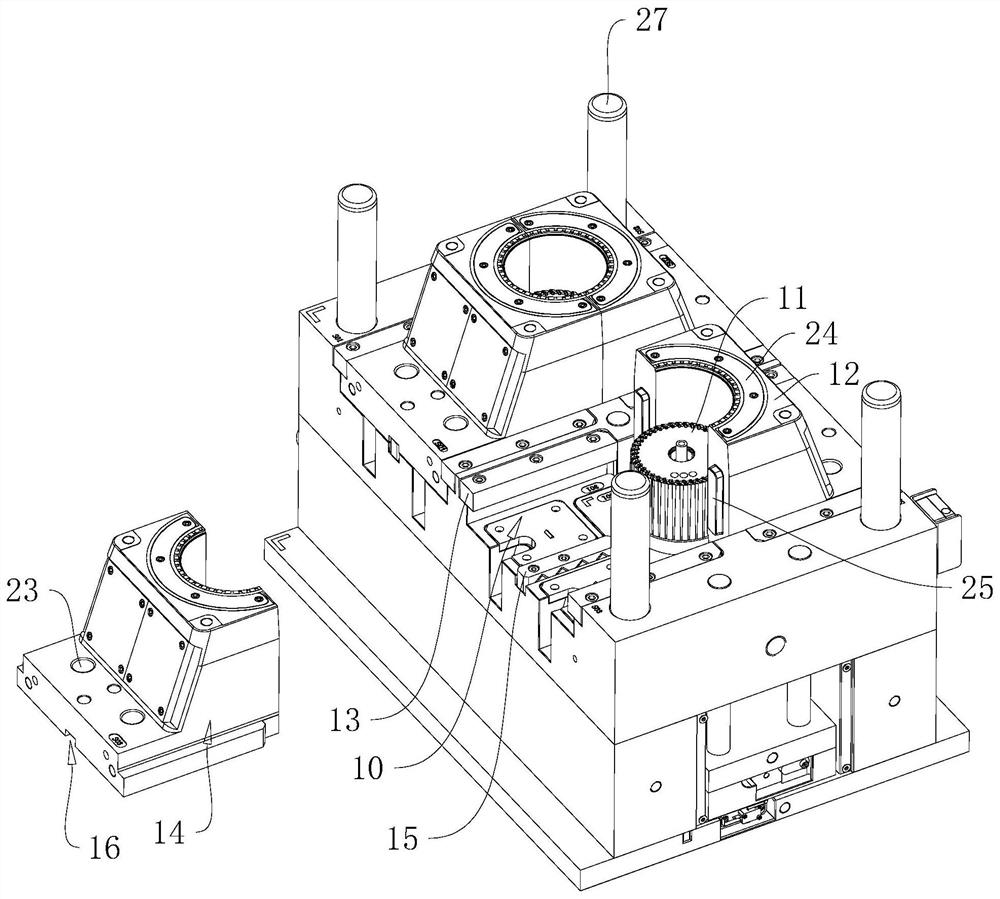

[0039] The following is attached Figure 1-7 The application is described in further detail.

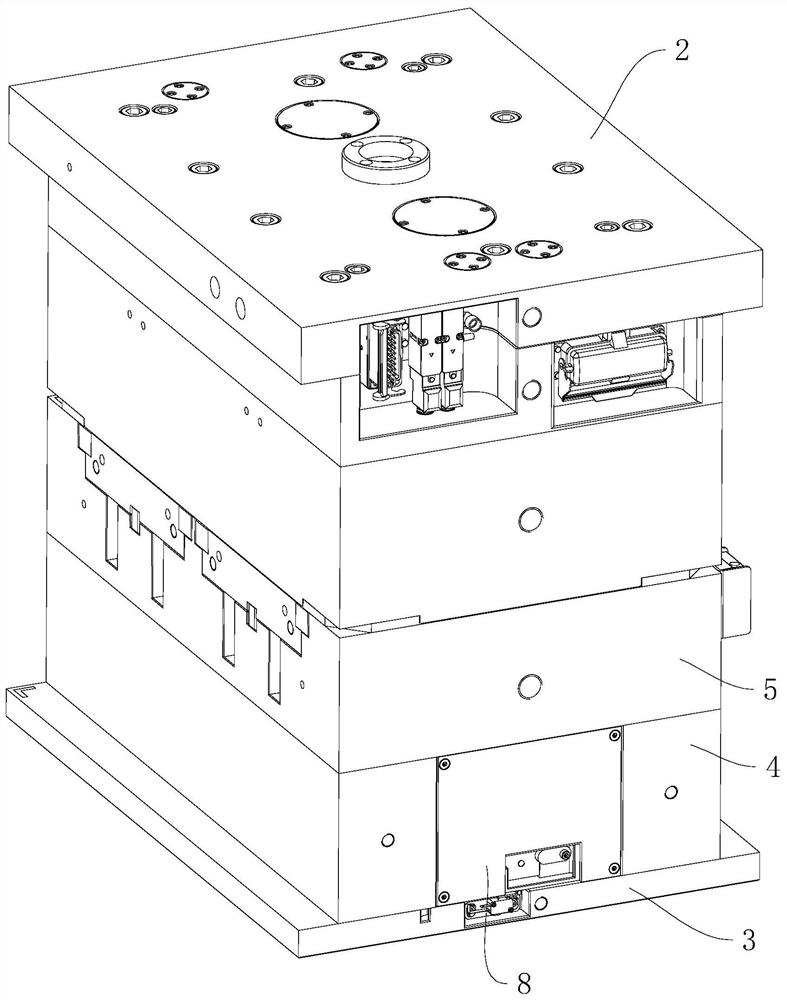

[0040] see figure 1 and figure 2 ,, a mold for producing centrifugal fan blades, including a movable mold 1 fixed in the injection molding machine that moves with the internal mechanism of the injection molding machine and a fixed mold 2 fixed in the injection molding machine, the movable mold 1 and the fixed mold 2 are interlocked combine.

[0041] The movable mold 1 includes a lower template 3 that can be fixed inside the injection molding machine by bolts, two square irons 4 that are fixed on one end of the lower template 3 by bolts at parallel intervals, and fixed on the bottom of the square iron 4 away from the end of the lower template 3 by bolts. Template 5, thimble plate 6 installed between two square irons 4, face needle plate 7 located at the end of thimble plate 6 close to lower formwork 5, two pieces of square iron 4 form ejector plate 6 and face needle plate 7. A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com