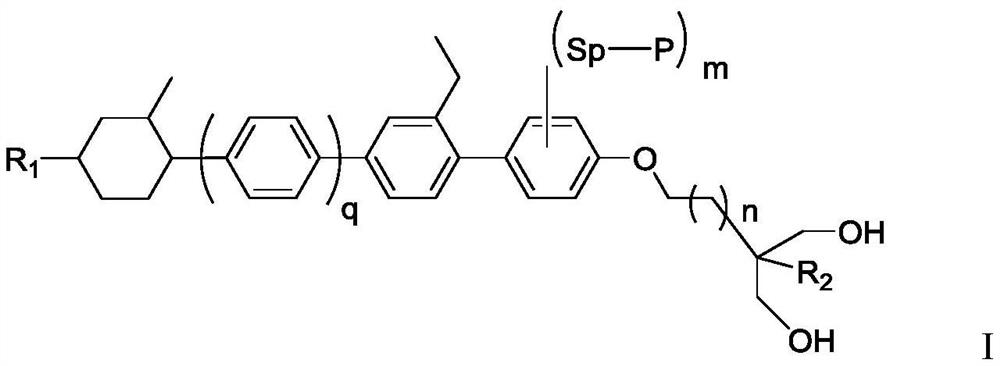

Negative liquid crystal composition and application thereof

A technology of liquid crystal composition and negative liquid crystal, which is applied in liquid crystal materials, nonlinear optics, optics, etc., can solve the problems of VA display resistance reduction and achieve good low-temperature mutual solubility, suitable for optical anisotropy, and high VHR effects

- Summary

- Abstract

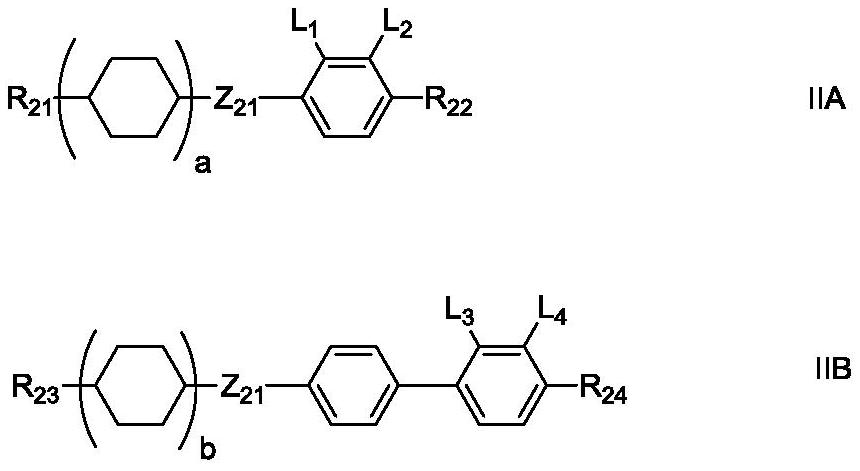

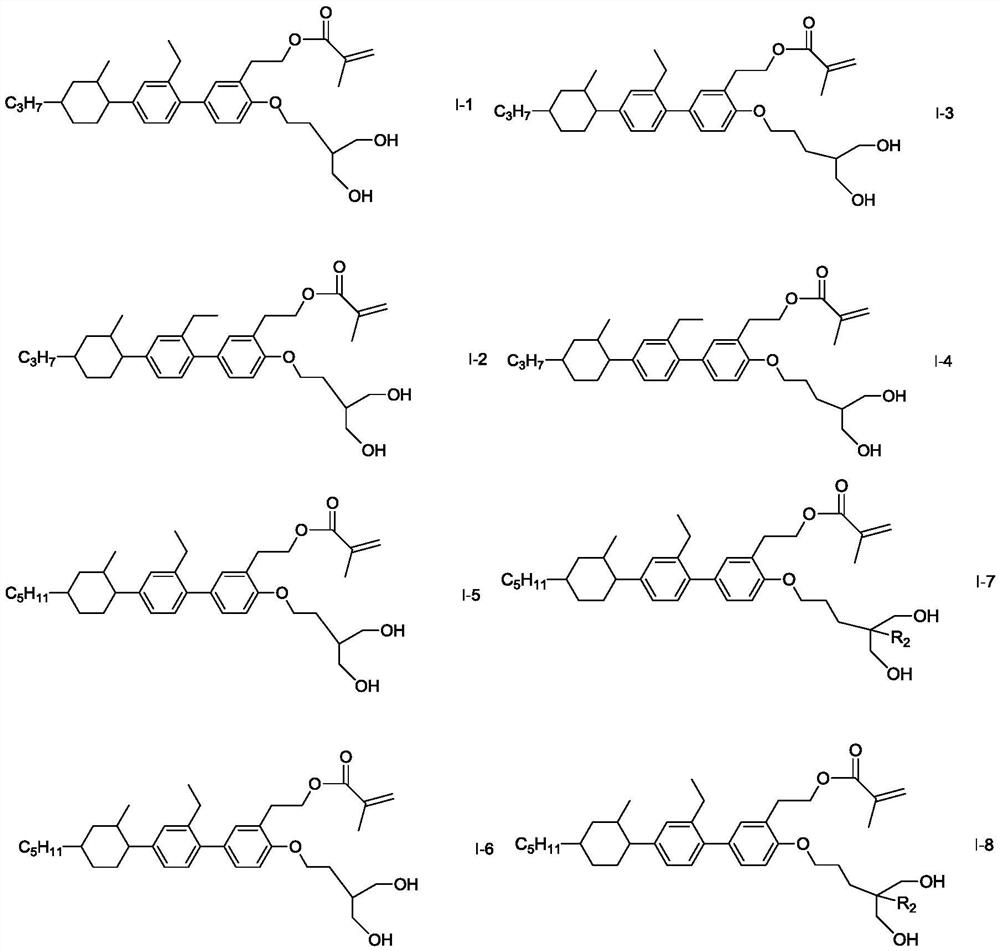

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] M1:

[0092] Configure the liquid crystal according to the following proportions to obtain the mixture M1, which is filled between the two substrates of the liquid crystal device for performance testing. The test data are shown in the following table:

[0093] Table 2 Nematic liquid crystal M1

[0094] components content% performance 3CCO1 2 Cp 74.8℃ 3CPO1 6 Dn 0.101 3CCV1 10 De -3.6 3CWO2 11 gamma 1

95 4CC3 8 K11 15.4 3PWO2 19 K33 14.9 5CC3 6 Ts-N <-30℃ 3CPP1 8 V2CCP1 5 3CPP2 8 3CCWO2 9 3CPWO2 4 2CPP2 4

[0095] M2:

[0096] Configure the liquid crystal according to the following proportions to obtain the mixture M2, which is filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0097] Table 3 Nematic liquid crystal M2

[0098]

[0099] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com