Pile sinking construction process for overlong inclined socketed pile of offshore bearing platform

A construction technique and pile sinking technology, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of inaccurate slope and penetration of super-long piles, meet the requirements of support strength, avoid displacement, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

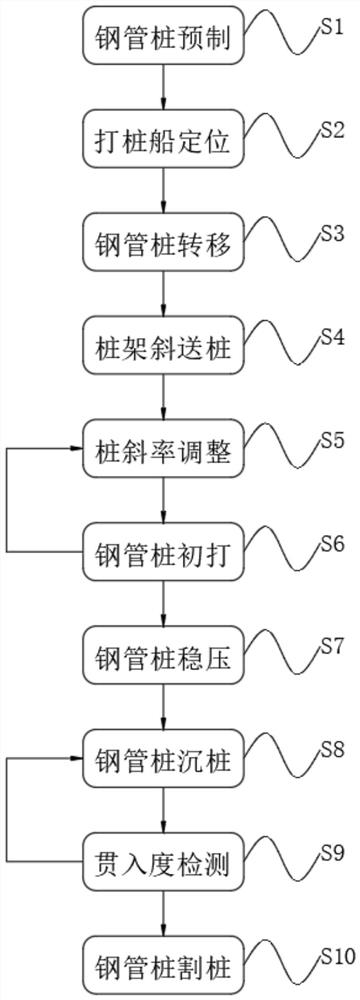

[0026] see figure 1 , a pile sinking construction process of super-long inclined rock-socketed piles for offshore caps in this embodiment, the construction process includes the following steps carried out in sequence:

[0027] S1 steel pipe pile prefabrication, generally using Q235 steel plate as raw material, cut by a professional cutting machine, curled into a spiral shape by a high-power plate rolling machine, and welded into a cylindrical shape by an automatic welding machine, the weld seam requires X Optical damage detection to ensure the quality of welding. After the welding constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com