Underground diaphragm wall joint water seepage treatment method

A technology of an underground diaphragm wall and a treatment method, which is applied in the field of water seepage treatment of the joints of the underground diaphragm wall, can solve the problems of untimely sealing of the gaps at the seepage, limited storage time of the grouting body, and inability to solidify in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-4 The application is described in further detail.

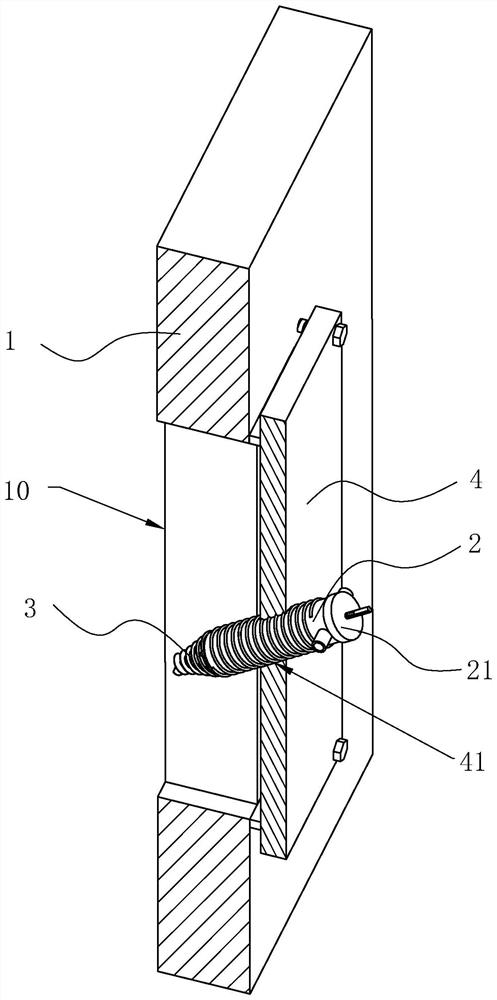

[0041] The embodiment of the present application discloses a method for treating water seepage in the joints of underground diaphragm walls. figure 1 and figure 2 , including the following steps:

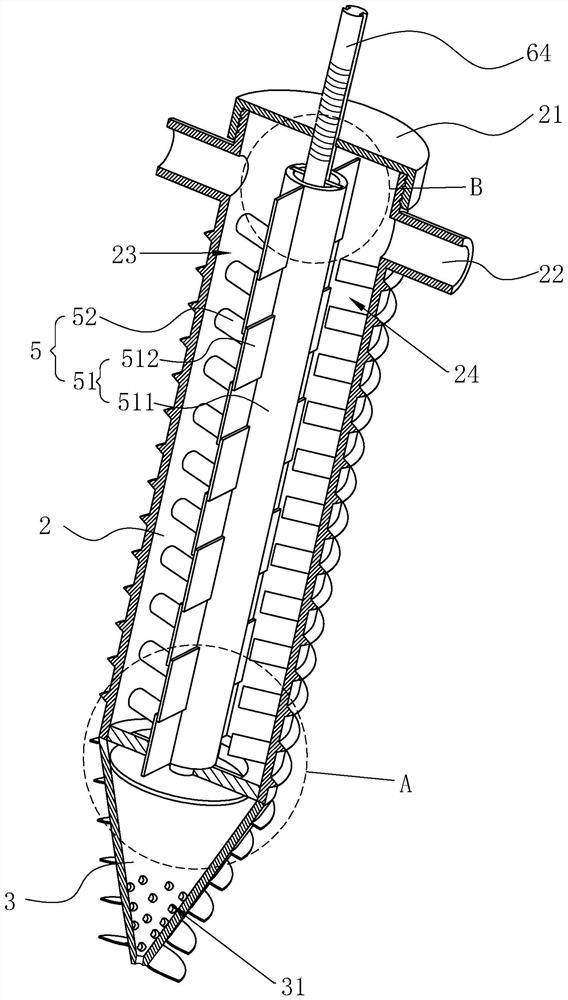

[0042] S1: The prefabricated installation plate 4, the installation plate 4 is obliquely downwardly penetrated with the grouting pipe 2; it is convenient for the grouting body to flow downward by its own gravity.

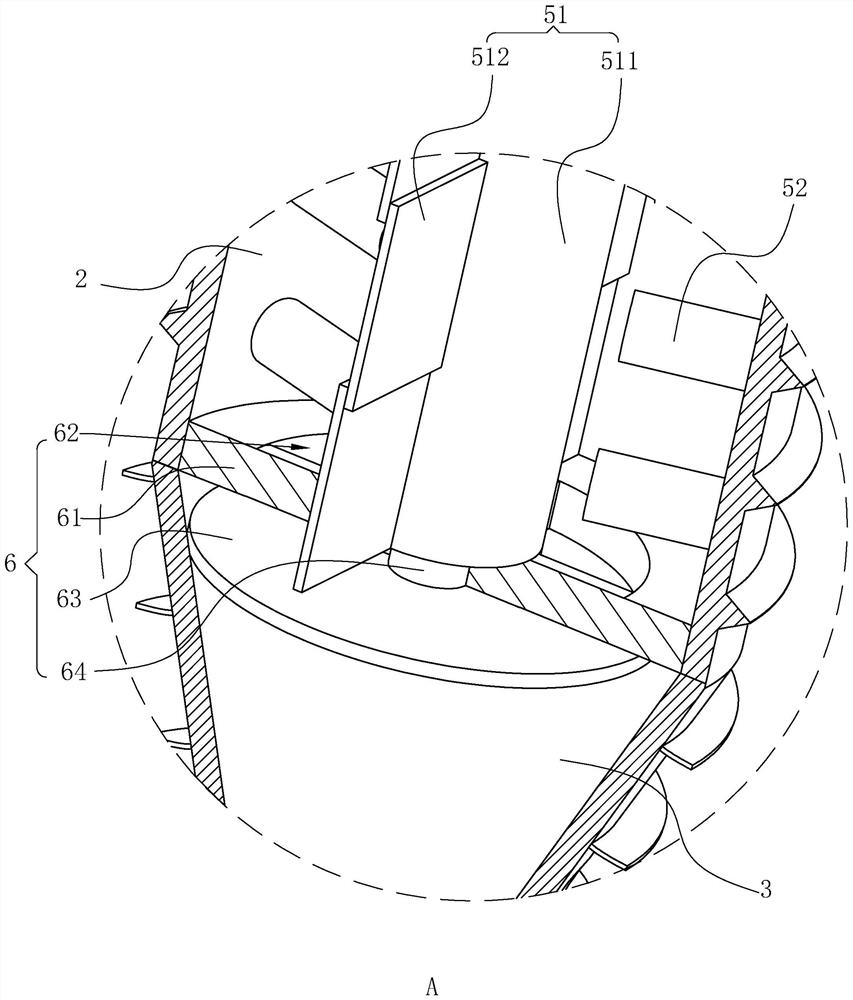

[0043] refer to figure 1 and figure 2 , the grouting pipe 2 is provided with an independent first chamber 23 and a second chamber 24, and the grouting pipe 2 is also provided with a mixing assembly 5 for mixing the grout of the first chamber 23 and the second chamber 24 , the inclined lower end of the grouting pipe 2 is coaxially connected with a grouting pipe 3 , and the diameter of the grouting pipe 3 gradually shrinks away from the grouting pipe 2 . The end of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com