Two-way ejector for storage tank

A storage tank and ejector technology, applied in general water supply conservation, chemical instruments and methods, waterway systems, etc., can solve the problems of inability to realize rainwater mixing and sludge flushing, low flushing efficiency of single nozzle structure, etc., and achieve excellent mechanics Balance performance, improve agitation and flushing efficiency, flow balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

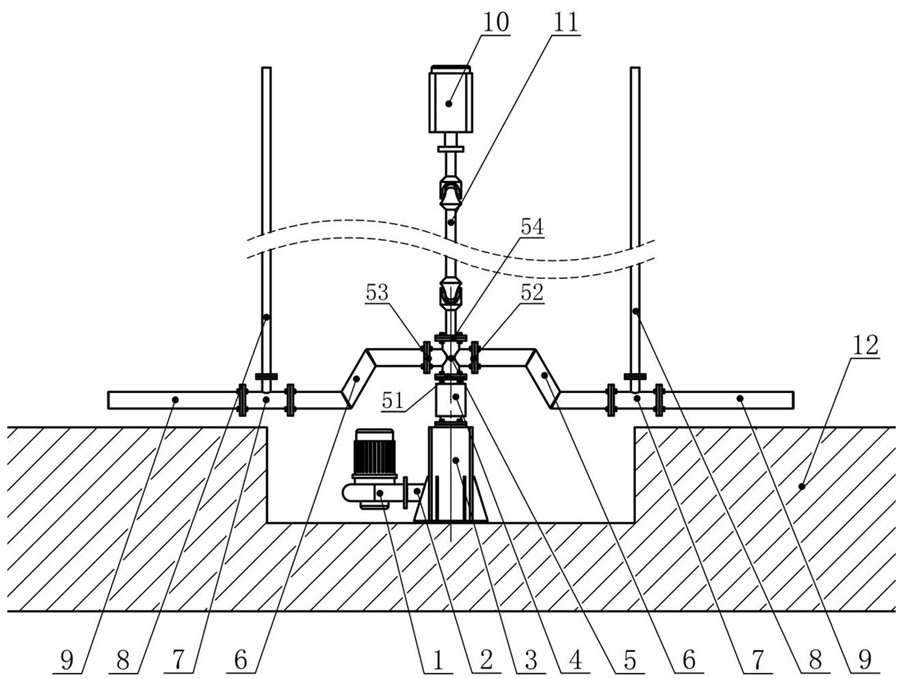

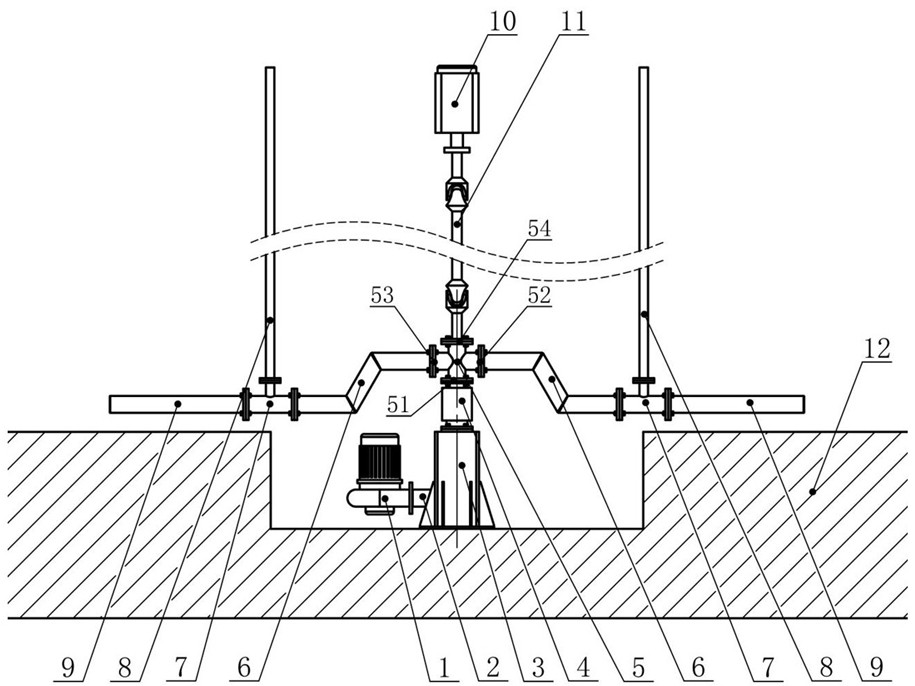

[0024] Such as figure 1 As shown, a double-pipeline rotary injector consists of a submersible pump 1, a connecting elbow 2, a base 3, a rotating seat 4, a tee pipe 5, an injection assembly and a driving device. The injection assembly is fixed in the storage tank 12 through the base 3 . In order to make the spray assembly close to the bottom of the pool and improve the flushing effect, the base and the submersible pump are installed in the sunken inner groove at the bottom of the storage tank. One end of the connecting elbow 2 is connected to the water outlet of the submersible pump 1 , and the other end is connected to one end of the rotating seat 4 through the base 3 . The bottom of the rotating seat 4 is fixed on the base 3. The rotating seat 4 is composed of a cylindrical seat body and a turntable. In the inner cavity, the three-way pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com