Protective glass defect detection equipment

A defect detection and glass protection technology, applied in mechanical equipment, measuring devices, instruments, etc., can solve the problems of easy deviation, limit, and scratches on the glass surface of the detection camera position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

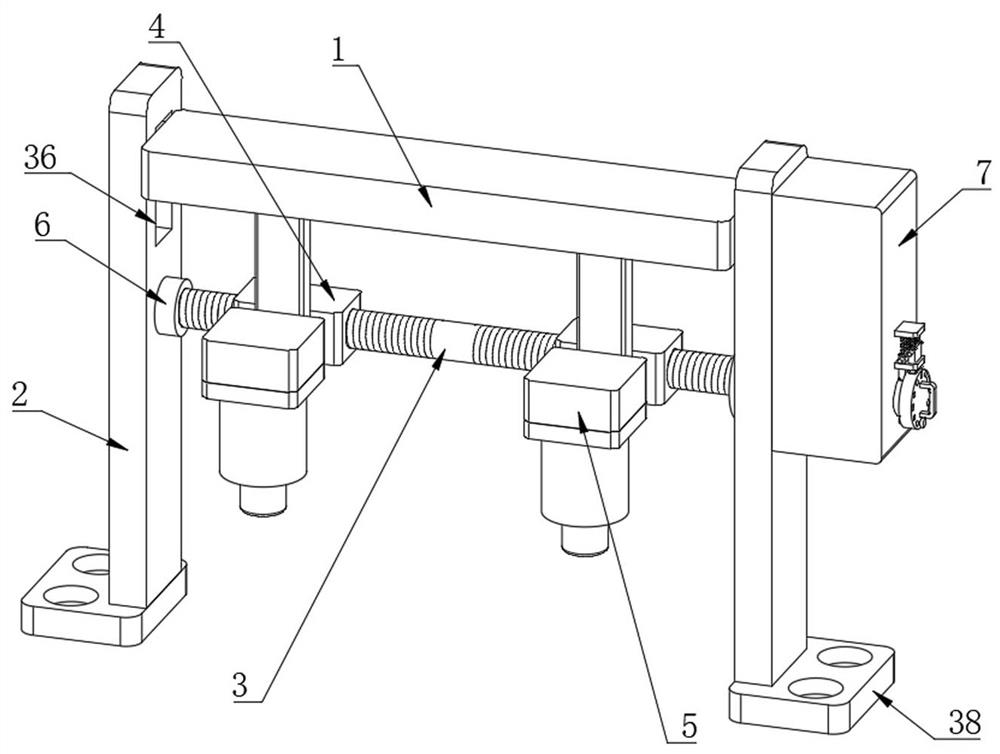

[0033] Embodiment one, by Figure 1 to Figure 8 Given, the present invention includes a support top plate 1, both sides of the support top plate 1 are provided with support side plates 2, a two-way screw rod 3 is provided below the support top plate 1, and two movable blocks are arranged between the two support side plates 2 4. The two-way screw rod 3 runs through two movable blocks 4, and the connection between the movable block 4 and the two-way screw rod 3 is threaded connection. There are two detection camera bodies 5 under the supporting top plate 1, and the detection camera body 5 and the movable block 4 is provided with a limit slide unit matched with the supporting top plate 1, one end of the two-way screw rod 3 is connected with one side of one of the supporting side plates 2 through the first bearing 6, and the other end of the two-way screw rod 3 runs through the other The side plate 2 is supported, and the second bearing 11 is provided at the penetration of the two...

Embodiment 2

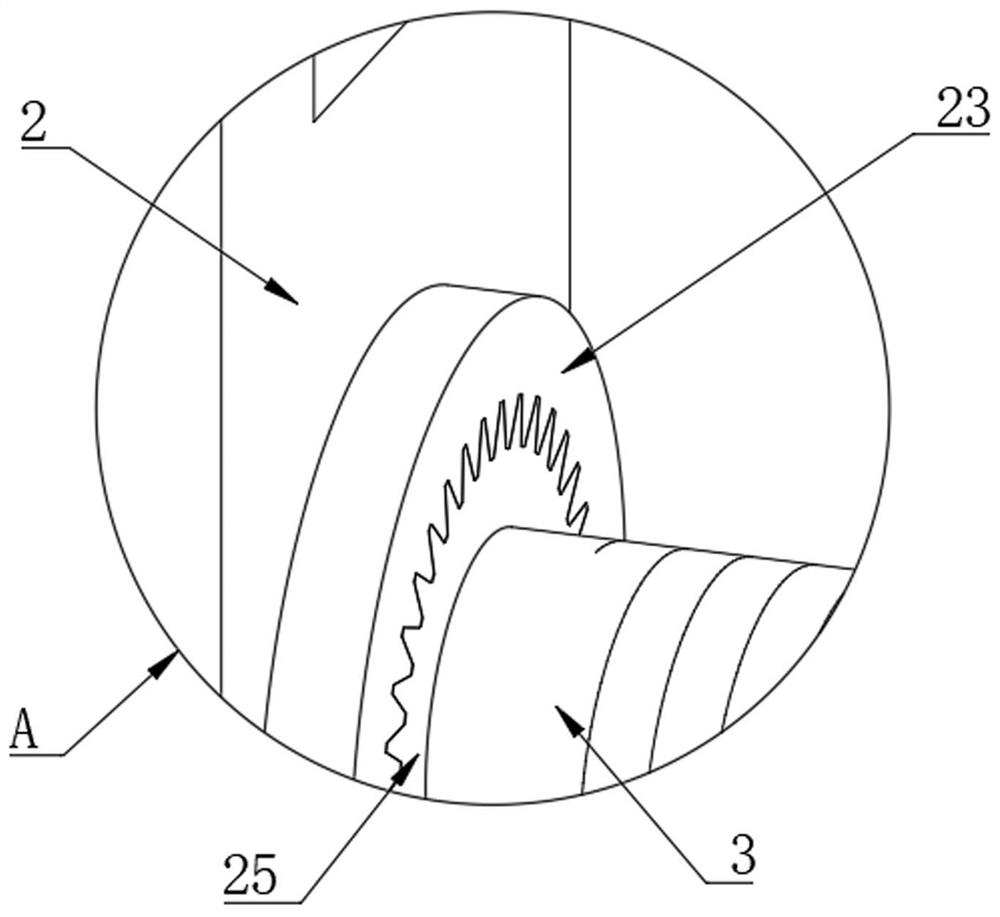

[0035] Embodiment two, on the basis of embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 with Figure 7 Given, the limiting rotation assembly includes a groove 16 provided at one end of the two-way screw rod 3, and one side of the inner wall of the groove 16 is provided with a card groove 17, and one end of the rotating shaft 13 is fixedly connected with a guide post 18, and one end of the guide post 18 Located in the groove 16, the end of the guide column 18 away from the rotating shaft 13 is fixedly connected with a block 19, and one side of the supporting side plate 2 is provided with a first gear 25, and the two-way screw rod 3 runs through the first gear 25, and the two-way wire The rod 3 is fixedly connected with the first gear 25, and the outside of the first gear 25 is provided with a gear ring 23. The gear ring 23 and the rotating shaft 13 are connected through a rotating part. The rotating part includes a fixed ring 21 sleeved on the outs...

Embodiment 3

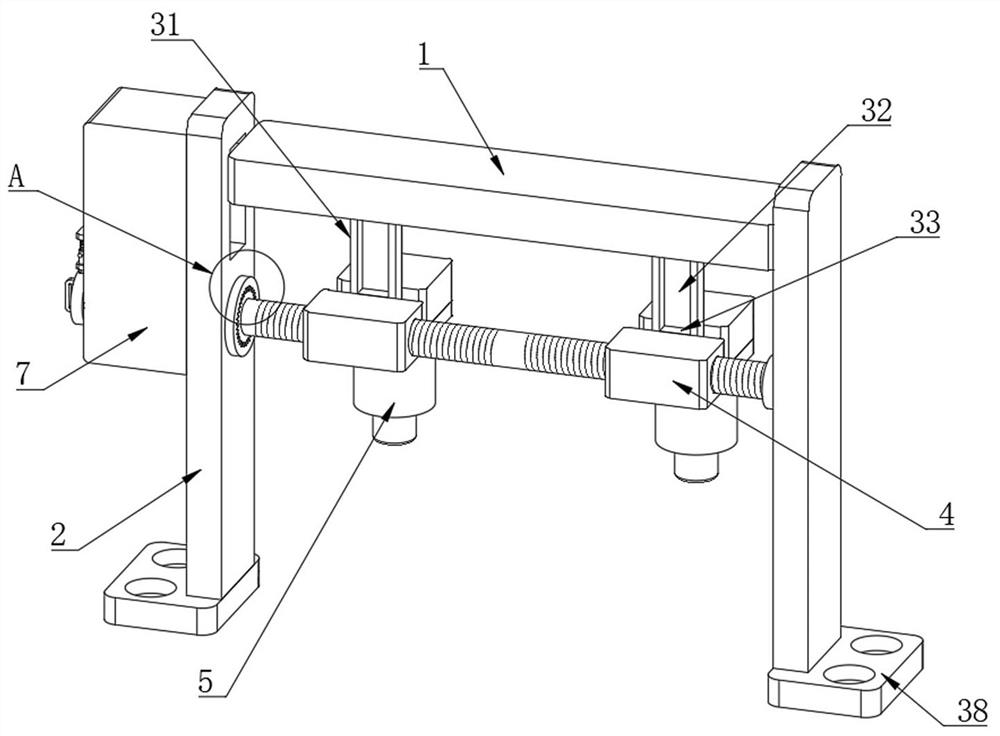

[0037] Embodiment three, on the basis of embodiment one, by figure 1 , Figure 4 , Figure 5 with Figure 8 Provided, the movable engagement limit assembly includes a movable plate 26 arranged in the control box 7, the rotating shaft 13 runs through the movable plate 26, the fifth bearing 29 is provided at the penetration of the rotating shaft 13 and the movable plate 26, and the inner wall of one side of the control box 7 Fixedly connected with a positioning plate 30, and the positioning plate 30 runs through the movable plate 26, one side of the movable plate 26 is fixedly connected with a tooth plate 28, the control box 7 is provided with a second gear 27, and the threaded column 10 runs through the second gear 27, And the threaded column 10 is fixedly connected with the second gear 27, the limit sliding unit includes a connecting plate 31 arranged between the movable block 4 and the detection camera body 5, one side of the connection plate 31 is fixedly connected with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com