Display device and manufacturing method thereof

A technology of display device and manufacturing method, which is applied in the direction of electric solid device, semiconductor device, electrical components, etc., can solve the problems of increasing the surface height difference of the display device and affecting the QLED packaging effect, and achieve the effect of improving the packaging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

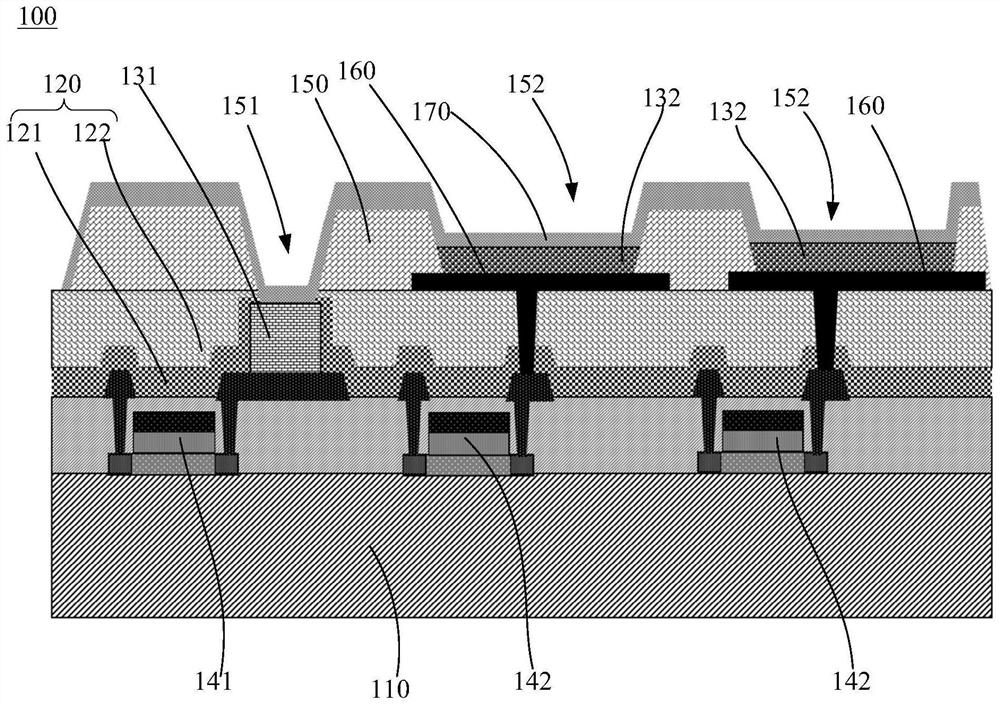

[0083] This embodiment provides a display device 100 .

[0084] Please refer to figure 1 As shown, the display device 100 of this embodiment includes a substrate 110 , a first driving TFT 141 , a second driving TFT 142 , a passivation layer 121 , a flat layer 122 , a pixel defining layer 150 , a first sub-pixel 131 and a second sub-pixel 132 .

[0085] The first driving TFT 141 and the second driving TFT 142 are arranged in an array on the substrate 110 .

[0086] The first sub-pixel 131 is a blue Micro-LED chip with a vertical structure. The first sub-pixel 131 is arranged on the source of the second driving TFT 142. The surface of the first sub-pixel 131 near the substrate 110 is completely connected to the first driving TFT 141 source contact.

[0087]The passivation layer 121 covers the first driving TFT 141 and the second driving TFT 142 . The planarization layer 122 covers the passivation layer 121 . The first sub-pixel 131 is buried in the intermediate layer 120 com...

Embodiment 2

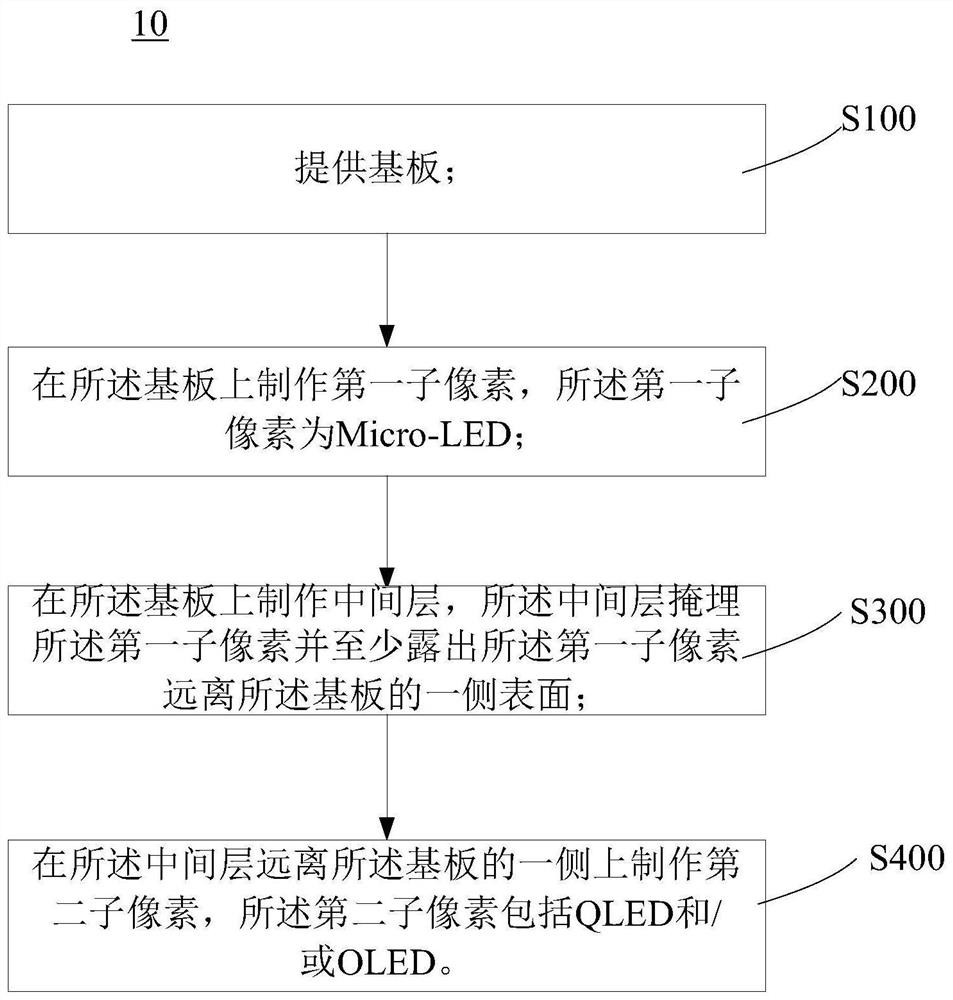

[0091] This embodiment provides a manufacturing method of the display device 100 . In this embodiment, some conventional processes for manufacturing the display device 100 may be omitted between steps and between specific steps before and after operations, and those skilled in the art may add process steps according to actual needs during the manufacturing process.

[0092] Please refer to Figure 3 to Figure 8 As shown, the manufacturing method of the display device 100 of this embodiment includes the following steps:

[0093] Step 1, providing a substrate 110 .

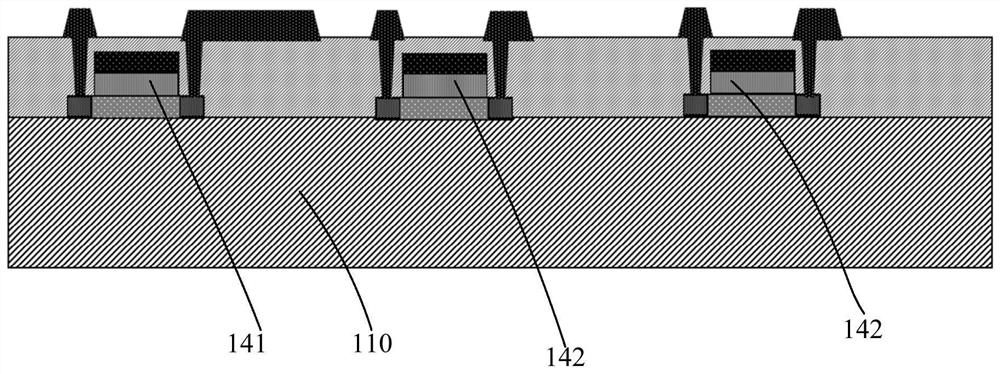

[0094] Step 2, such as image 3 As shown, the first driving TFT 141 and the second driving TFT 142 are fabricated on the substrate 110 , wherein the source surface area of the first driving TFT 141 is larger.

[0095] Step 3, such as Figure 4 As shown, the first sub-pixel 131 is transferred to the source of the first driving TFT 141 by a transfer process, and the first sub-pixel 131 is a blue Micro-LED chip w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com